Introduction

Down-the-hole drilling is a crucial process in the well drilling industry. It involves using a drill and hammer drill to create boreholes for various purposes. Well drilling is essential for accessing groundwater, oil, or gas reservoirs, making it an indispensable part of many industries. Using a pneumatic drill offers numerous benefits, including increased efficiency and reduced manual labor.

Understanding Down the Hole Drilling

Down-the-hole drilling refers to a method in which the hammer drill creates holes deep into the ground, allowing access to valuable resources such as water or minerals. This process involves high-powered equipment like pneumatic drills to ensure precision and depth in drilling operations.

Importance of Well Drilling

Well drilling is a critical process that provides numerous benefits to our society. Here are some of its key advantages:

- Access to clean water: Well drilling offers a reliable source of clean water for communities, particularly in regions with limited surface water resources. This is especially important for remote areas or those that experience frequent droughts.

- Energy production: Wells are essential for extracting oil and gas, significant contributors to global energy production. We can tap into these vital resources by drilling wells to meet our energy demands.

Well drilling is indispensable in securing clean water supplies and fostering energy production. It is a practice that underpins many aspects of our daily lives.

Benefits of Pneumatic Drill

Pneumatic drills are a powerful choice for tough jobs. Here are some of the benefits they offer:

- Increased Speed and Accuracy: Compared to electric drills, pneumatic drills deliver more torque and can spin at higher speeds. This translates to faster drilling and cleaner, more precise holes.

- Durability and Power: Built to handle demanding applications, pneumatic drills can easily handle tough materials like concrete and steel. They're less likely to suffer damage from overload than electric drills.

- Lightweight Design: Despite their power, pneumatic drills are typically lighter than electric drills. This reduces operator fatigue and makes them easier to maneuver in tight spaces.

Pneumatic drills are valuable for professional applications requiring power, precision, and durability.

Choosing the Right Equipment

When it comes to down the hole drilling, selecting the best drill and hammer drill is crucial for successful well drilling. The right equipment can make all the difference in efficiency and accuracy. With various options available, exploring different types of well drill machines is essential to find the perfect fit for your project. One standout choice is the Tianhe drill hammer drill, known for its reliability and performance in challenging drilling conditions.

Selecting the Best Drill and Hammer Drill

Choosing the right drill or hammer drill depends on what you'll be using it for. Here are some key factors to consider:

- Power: Whether corded or cordless, the drill's power (measured in watts for corded and voltage for cordless) determines the size and hardness of the materials it can handle. Higher-wattage/higher-voltage drills tackle tougher jobs.

- Speed: Variable speed control allows you to adjust the drilling speed to the material. Lower speeds provide more control for delicate tasks, while higher speeds bore through tougher materials faster.

- Durability: A well-built drill will last longer, especially with frequent use or demanding projects. Look for a drill with strong housing and metal gears.

By considering these factors and matching them to your specific needs, you'll be well on your way to selecting the perfect drill or hammer drill for your next project.

Exploring Different Types of Well Drill Machines

Well drilling projects come in all sizes, and so do the machines that tackle them. By understanding the various types of well drill rigs available, you can ensure you have the right tool for the job, leading to efficient and successful well drilling.

Here's a breakdown of some common well drill machines, categorized by their functionality:

- Cable Tool Drilling Rigs: These classic rigs utilize a heavy bit attached to a cable for a hammering motion, effective for penetrating hard rock formations.

- Rotary Drilling Rigs: These rigs employ a rotating bit to drill through softer soils. They often come with mud or air rotary options, using either mud or air to remove cuttings from the borehole.

- Down-the-Hole (DTH) Hammer Drilling Rigs: DTH rigs utilize a powerful down-hole hammer for maximum drilling force. They excel in hard rock and uneven terrain.

- Reverse Circulation Drilling Rigs: This method uses pressurized air to circulate drilling fluids upwards, allowing for continuous chip removal and efficient drilling in unconsolidated formations.

- Hydraulic Auger Drilling Rigs: Ideal for shallow wells and large-diameter holes in soft soil conditions, auger rigs utilize a giant corkscrew-like bit to remove soil.

- Truck-Mounted and Trailer-Mounted Rigs: These classifications refer to how the drilling equipment is transported. Truck-mounted rigs offer greater mobility, while trailer-mounted rigs are often more affordable and easier to maneuver in tight spaces.

Considering factors like power source (electric vs. diesel/gasoline) and portability alongside the type of drilling method will ultimately guide you toward the most suitable well drill machine for your project.

Advantages of Tianhe Drill Hammer Drill

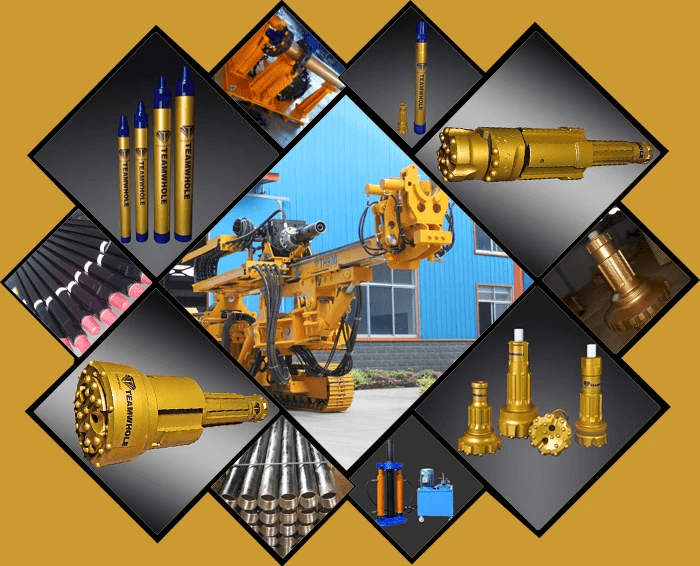

The Tianhe drill hammer drill is an excellent choice for down the hole drilling due to its innovative design and exceptional performance. This versatile tool offers power and precision, making it suitable for various drilling applications. With advanced features tailored to meet industry demands, this equipment provides reliability and efficiency on every job site.

The Tianhe drill hammer drill's innovative design includes a powerful motor that delivers high torque and speed, allowing for efficient drilling through various rock and soil types. The tool's precision control further enhances this exceptional performance, which enables operators to maintain accuracy and consistency throughout the drilling process. Whether for mining, construction, or geotechnical projects, this drill hammer provides the power and precision needed to do the job effectively.

Proper Site Preparation

Proper site preparation is crucial for success in down-the-hole drilling. Ensuring adequate space for your drill and hammer drill is essential to avoid obstructions or accidents during operation. Additionally, ground stability plays a significant role in the effectiveness of your drilling operation, as unstable ground can lead to equipment damage and safety hazards. That's why Tianhe's expert advice on site preparation is invaluable, providing you with the necessary guidance to set up your drilling site for optimal results.

Ensuring Adequate Space for Drill Hammer Drill

Enough space for your drill and hammer drill is vital for efficient and safe operation. It allows for smooth equipment movement and minimizes the risk of collisions with surrounding objects or structures. By carefully planning the layout of your drilling site, you can ensure that there are no spatial limitations that could hinder the performance of your equipment. Tianhe understands the importance of space management when it comes to down-the-hole drilling and provides expert recommendations on how to optimize your workspace.

Importance of Ground Stability

Ground stability is critical in well drilling, especially when using a hammer drill and rotary drill combination. Unstable ground conditions can pose serious risks to both personnel and equipment, leading to potential accidents and project delays. By assessing the stability of the ground beforehand, you can take necessary precautions to mitigate any instability issues and ensure a safer working environment. Tianhe emphasizes the significance of ground stability in down the hole drilling and offers insights into how to address this aspect effectively.

Tianhe's Expert Advice on Site Preparation

Tianhe's expertise in down-the-hole drilling extends beyond providing top-notch equipment—they also offer valuable advice on site preparation. With years of experience in the industry, their team understands what it takes to create an ideal drilling environment. From recommending specific layouts for optimal equipment placement to advising on ground assessment techniques, Tianhe's expert guidance can significantly enhance the overall efficiency and safety of your well drilling project.

Safety Measures

When it comes to down the hole drilling, safety should always be the top priority. Proper training for rotary drills is essential to ensure operators understand the equipment and use it safely. Understanding potential hazards, such as falling objects or unstable ground, is crucial for preventing accidents on the job site. At Tianhe, we prioritize safety and quality control in all our drilling equipment to provide a secure working environment for our customers.

Importance of Proper Training for Rotary Drill

Proper training for using a rotary drill prevents accidents and ensures efficient operation. Operators must be familiar with the equipment's functions and safety protocols before starting drilling activities. By providing comprehensive training programs, Tianhe ensures operators have the knowledge and skills to operate rotary drills safely and effectively.

Understanding Potential Hazards

In any well drilling project, inherent risks are associated with operating heavy machinery and working in challenging environments. Potential hazards such as cave-ins, equipment malfunctions, or high-pressure air leaks must be carefully considered and mitigated through proper safety measures. At Tianhe, we conduct thorough risk assessments and provide clear guidelines for identifying and addressing potential hazards on the job site.

Tianhe's Focus on Safety and Quality Control

At Tianhe, we are committed to maintaining the highest safety and quality control standards in all our drilling equipment. Our products undergo rigorous testing to meet industry regulations and exceed performance expectations. By prioritizing safety features and implementing strict quality control measures, we strive to provide our customers with reliable tools that enhance workplace safety during down the hole drilling operations.

In addition to our commitment to safety and quality control, we also prioritize regular maintenance and care for our drilling equipment. Our experienced technicians conduct thorough inspections and maintenance checks to ensure that all equipment is in optimal working condition. By adhering to a strict maintenance schedule, we can prolong the lifespan of our products and minimize the risk of unexpected malfunctions during drilling operations.

Maintenance and Care

As we delve into the crucial aspect of maintenance and care in down-the-hole drilling, it's essential to focus on extending the lifespan of pneumatic drills. Regular maintenance checks, proper lubrication, and timely replacement of worn-out parts are key to ensuring the longevity and optimal performance of your drill and hammer drill equipment.

When it comes to efficient use of drill and hammer drill, always remember to match the right tool for the job. Understanding the specific requirements of your well drilling project will help you maximize efficiency and minimize wear and tear on your equipment. Proper handling, correct usage, and regular cleaning also play a significant role in maintaining peak performance.

Tianhe recommends following a scheduled maintenance plan tailored to your specific drill hammer drill model for expert maintenance recommendations. Our team has extensive experience providing comprehensive maintenance guidelines covering everything from routine checks to troubleshooting common issues. By adhering to our recommendations, you can ensure that your equipment remains in top condition for years.

Maximizing Efficiency

In the world of down the hole drilling, maximizing efficiency is crucial for success. With the right equipment, such as a powerful drill and hammer drill combination, you can optimize speed and accuracy to ensure a smooth drilling process. This saves time and maximizes the effectiveness of your well drilling operations.

Optimizing Speed and Accuracy with the Right Equipment

When it comes to down-the-hole drilling, speed and accuracy are key factors in achieving excellent results. Choosing the right equipment, such as a high-quality pneumatic drill and well drill machine, can significantly improve efficiency. The combination of a hammer drill and rotary drill ensures precise drilling at a faster pace, making it easier to reach greater depths.

Advantages of Hammer and Drill Combinations

Hammer and drill combinations are powerful for tackling tough drilling jobs. Here's why they're a must-have for any down-the-hole drilling operation:

- Penetrates Tough Materials: The hammering action delivers the force needed to break through hard rock formations that would stall a regular drill.

- Maintains Accuracy: Despite the added power, the drill function ensures precise borehole creation, which is crucial for successful down-the-hole projects.

- Versatility Across Conditions: This combination tool adapts to various geological settings. Whether you're facing hard rock or softer materials, a hammer drill can handle it efficiently.

Hammer and drill combinations offer unmatched power, precision, and versatility for down-the-hole drilling. They're a true game-changer for tackling any drilling challenge.

Tianhe's Innovative Solutions for Down the Hole Drilling

Tianhe offers innovative solutions that revolutionize down-the-hole drilling processes. Their state-of-the-art hammer drill technology combined with advanced well drill machines ensures maximum efficiency in all drilling operations. With their commitment to excellence and continuous improvement, Tianhe provides cutting-edge equipment that sets new industry standards.

Take Your Well Drilling to the Next Level

Down the hole drilling is a crucial process that requires the right equipment and expertise to ensure success. With Tianhe's commitment to excellence, you can trust that your well drilling needs will be met with top-quality products and expert advice. Take your well drilling to the next level with our innovative solutions and maximize efficiency like never before.

Ensuring Success in Down the Hole Drilling

Choosing the right drill and hammer drill is essential for ensuring success in down the hole drilling. With Tianhe's range of well drill machines and pneumatic drills, you can rest assured that you have the best equipment for the job. Proper site preparation and safety measures are also vital in achieving successful results.

Tianhe's Commitment to Excellence

Tianhe is dedicated to providing high-quality products and expert advice to meet all your well drilling needs. Our focus on safety and quality control ensures that you can rely on our equipment for efficient and safe down the hole drilling. Trust Tianhe for all your hammer drill and rotary drill requirements.

With Tianhe's innovative solutions, you can take your well-drilling operations to new heights of efficiency and productivity. Our maintenance recommendations will help extend the lifespan of your pneumatic drills, while our tips for efficiently using hammer drills will optimize speed and accuracy. Trust Tianhe to elevate your down the hole drilling experience.