Introduction

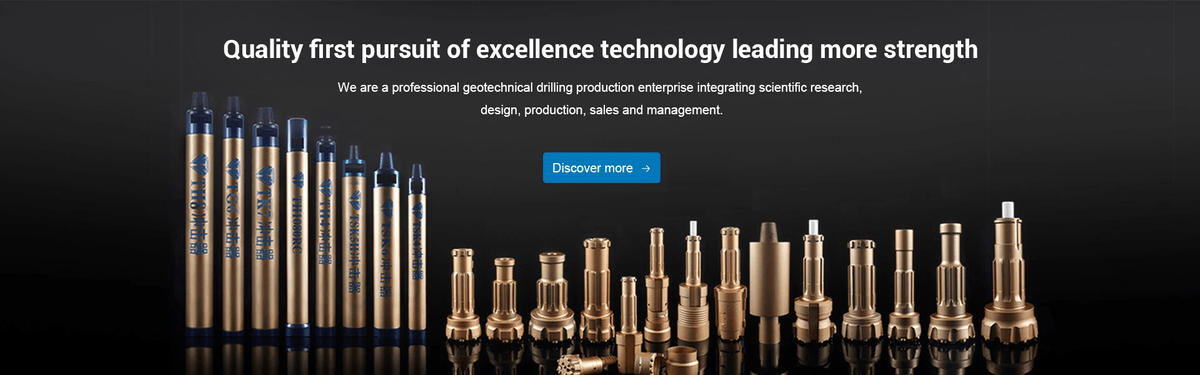

Are you in the market for a top-notch down the hole hammer for sale? Look no further than Teamwhole, your go-to source for high-quality equipment and tools for down the hole drill and well drilling. When it comes to finding the best downhole hammer, quality and durability are key factors to consider, and Teamwhole has got you covered with their diverse line of DTH bits.

Discovering the Best Down the Hole Hammer for Sale

Teamwhole offers a wide selection of down the hole hammers for sale, designed to meet various drilling needs and challenges. Whether you're tackling hard rock formations or softer materials, their range of DTH hammers ensures superior performance and efficiency in your drilling operations.

Teamwhole's DTH hammers are engineered to deliver consistent and reliable performance, even in the most challenging drilling conditions. With a focus on durability and precision, their hammers are built to withstand high impact and abrasion, ensuring a longer lifespan and reduced downtime for maintenance. You can count on Teamwhole's DTH hammers to keep your drilling operations running smoothly and efficiently.

Exploring Teamwhole’s Diverse Line of DTH Bits

When it comes to downhole drill bits, Teamwhole stands out with their diverse range of options suitable for different applications. From standard drilling to more specialized tasks, their line of DTH bits is engineered to deliver exceptional results across various industries.

Teamwhole’s commitment to quality and durability is evident in their meticulous attention to detail during manufacturing. Each DTH bit is constructed using high-quality materials and cutting-edge technology to ensure longevity and reliable performance in demanding drilling conditions. This dedication to excellence sets Teamwhole apart as a trusted provider of top-tier downhole drill bits for various industrial applications.

Importance of Quality and Durability

Downhole drilling demands the best. Here's how Teamwhole DTH bits set themselves apart:

- Superior Materials: Teamwhole is committed to using high-quality alloy steel and advanced heat-treatment processes. This creates DTH bits with exceptional resistance to wear and tear, even under demanding drilling conditions.

- Precision Engineering: Teamwhole's DTH bits go beyond just tough materials. Precision engineering ensures each bit is perfectly designed for its intended application, maximizing performance and lifespan.

- Rigorous Testing: Don't settle for untested claims. Teamwhole rigorously tests each DTH bit to guarantee it meets the highest standards. This translates to consistent reliability and minimizes downtime on your projects.

Focusing on quality and durability at every stage, Teamwhole DTH bits empower you to achieve optimal drilling performance and efficiency. Maximize your productivity and minimize downtime—choose Teamwhole.

What Sets Teamwhole's DTH Bits Apart

When it comes to finding the best down the hole hammer for sale, Teamwhole stands out with their high-quality alloy steel and advanced heat-treatment. This ensures that their DTH bits are built to withstand the toughest drilling conditions and deliver exceptional performance.

High-Quality Alloy Steel and Advanced Heat-Treatment

Teamwhole's DTH bits are crafted from top-grade alloy steel, making them incredibly durable and resistant to wear and tear. The advanced heat-treatment process further enhances their strength, ensuring that they can handle the rigors of down the hole drilling without compromising on performance.

Additionally, the high-quality alloy steel used in Teamwhole's DTH bits provides extreme protection against wear and fatigue, ensuring a longer lifespan for the equipment. This means less downtime for maintenance and repairs, ultimately saving time and money for drilling operations. The advanced heat-treatment process enhances strength and improves resistance to heat and pressure, making these DTH bits a reliable choice for demanding drilling tasks.

Extreme Protection Against Wear and Fatigue

Teamwhole's commitment to quality is evident in their DTH bits, which are designed to protect against wear and fatigue. This means they can maintain their cutting efficiency over prolonged use, allowing for uninterrupted drilling operations without frequent replacements.

Teamwhole's DTH bits feature four different bit head face designs, each carefully engineered to optimize drilling performance in various rock formations. Whether it's a soft or hard formation, their DTH bits are designed to deliver superior penetration rates and longer bit life. This versatility allows for efficient drilling in various geological conditions, making Teamwhole's DTH bits a reliable choice for any drilling project.

Four Different Bit Head Face Designs

With four different bit head face designs available, Teamwhole offers versatility to tackle various rock formations and drilling challenges. Whether flat, concave, convex or drop center designs, there's a suitable option for every downhole well drilling application. The flat design is ideal for soft formations, providing stability and even cutting. On the other hand, the concave design excels in hard rock formations by enhancing cuttings evacuation and preventing bit balling. Meanwhile, the convex design is perfect for abrasive formations due to its increased protection against wear and tear.

Two Different Carbide Shapes

Teamwhole's DTH bits come with two different carbide shapes – spherical and ballistic – providing flexibility to address specific drilling requirements. This level of customization ensures that each bit is optimized for maximum efficiency in different rock types and formations.

Teamwhole's commitment to providing DTH bits with two different carbide shapes demonstrates its dedication to meeting the diverse needs of drilling operations. By offering spherical and ballistic carbide shapes, it ensures that each bit can be tailored to the specific demands of different rock types and formations. This level of customization enhances drilling efficiency and reflects Teamwhole's understanding of the nuanced challenges faced in various drilling scenarios.

Finding the Right Size and Diameter

When finding the right size and diameter for your down the hole drill, Teamwhole has you covered with a range from 3 to 47 inches (76mm-1200mm) in diameter. Whether you're tackling a small-scale project or a large-scale drilling operation, Teamwhole's DTH bits come in various sizes to meet your specific needs.

Range from 3 to 47 (76mm-1200mm) in Diameter

Teamwhole offers an extensive range of diameters for their downhole hammers, ensuring that you can find the perfect fit for your drilling requirements. With options ranging from 3 inches to 47 inches, you can confidently select the ideal size for your down the hole well drilling projects, no matter the scale.

Teamwhole's downhole hammers are designed to be compatible with most leading hammer shanks, ensuring that you can seamlessly integrate them into your existing drilling equipment. This compatibility makes it easier for you to upgrade your drilling operations without replacing all of your current tools, saving you time and money. Whether you're using DHD, QL, or SD hammer shanks, Teamwhole has a solution that will work for you.

Compatibility with Most Leading Hammer Shanks

In addition to their diverse diameter range, Teamwhole's DTH bits are compatible with most leading hammer shanks in the market. This compatibility ensures that you can seamlessly integrate their high-quality bits into your existing equipment, making upgrading and enhancing your drilling operations easier than ever.

Furthermore, Teamwhole's DTH bits are designed to tackle any rock formations and challenges that may arise during drilling operations. These bits can handle the job precisely and efficiently, whether dealing with hard, abrasive rock or softer, more fractured formations. This versatility ensures that you can rely on Teamwhole's DTH bits to deliver consistent performance in various drilling conditions.

Tackling Any Rock Formations and Challenges

Teamwhole's DTH bits are designed to tackle any rock formations and challenges that come your way during drilling operations. Whether you're dealing with hard rock or abrasive formations, their durable and reliable bits are up to the task, delivering exceptional performance and longevity.

Why Teamwhole is the Go-To Choice

When it comes to finding the best down the hole hammer for sale, Teamwhole stands out for its unwavering commitment to quality and durability. Their DTH bits are meticulously crafted using high-quality alloy steel and advanced heat-treatment, ensuring exceptional performance in down the hole drilling operations.

Commitment to Quality and Durability

Teamwhole's dedication to quality and durability is evident in their downhole hammer products. Each DTH bit undergoes rigorous testing to guarantee extreme protection against wear and fatigue, providing long-lasting reliability in demanding drilling conditions. With Teamwhole, you can trust that your investment will deliver consistent performance and durability.

Furthermore, Teamwhole's commitment to quality and durability extends beyond its products. Its customer service and technical support teams are dedicated to ensuring that every customer receives the necessary assistance and guidance to maximize the performance and lifespan of its DTH bits. This level of ongoing support sets Teamwhole apart from its competitors, providing peace of mind for customers in any drilling application.

Superior Performance in Various Applications

Teamwhole's DTH bits are designed to excel in a wide range of applications, making them the top choice for down the hole well drilling projects. Whether you're tackling soft or hard rock formations, their four different bit head face designs and two different carbide shapes ensure superior performance across diverse drilling environments.

Teamwhole's DTH bits are designed to excel in a wide range of applications and offer exceptional durability and longevity, making them the top choice for down-the-hole well drilling projects. With their advanced engineering and precision manufacturing, these bits can withstand the toughest drilling conditions, ensuring reliable performance over extended periods of use. This makes them a cost-effective option for companies looking to maximize their drilling efficiency without compromising on quality.

Meeting the Needs of Different Industries

From mining and construction to geothermal drilling, Teamwhole's DTH bits are engineered to meet the specific needs of different industries. Their wide range of sizes (ranging from 3 to 47 inches in diameter) and compatibility with most leading hammer shanks make them a versatile solution for various drilling operations.

With Teamwhole's unwavering commitment to quality and durability, superior performance across various applications, and ability to meet the needs of different industries, it's clear why they are the go-to choice for anyone seeking top-notch DTH bits for sale. Don't settle for subpar equipment – make an informed decision with Teamwhole and unlock efficiency and productivity in your drilling operations!

Ensure Long-Term Success with Quality DTH Bits

When it comes to finding the best down the hole hammer for sale, Teamwhole is undoubtedly the go-to choice. Their commitment to quality and durability ensures that you are making an informed decision when selecting their DTH bits. With Teamwhole's high-quality products, you can ensure long-term success in your down the hole drill operations, unlocking efficiency and productivity in drilling operations.

Making an Informed Decision with Teamwhole

Teamwhole's diverse line of DTH bits offers extreme protection against wear and fatigue, thanks to their high-quality alloy steel and advanced heat-treatment. This ensures that you invest in a product that will withstand the toughest downhole well drilling challenges. By choosing Teamwhole, you are making an informed decision to benefit your drilling operations in the long run.

Teamwhole's commitment to quality and innovation sets them apart in the industry. With their cutting-edge technology and dedication to research and development, you can trust that you are getting the most advanced DTH bits on the market. This forward-thinking approach ensures that Teamwhole will continue to provide top-notch products that meet the evolving needs of the drilling industry, giving you peace of mind for the long-term success of your operations.

With four different bit head face designs and two different carbide shapes, Teamwhole's DTH bits cater to a wide range of rock formations and challenges. Their compatibility with most leading hammer shanks makes them versatile for various applications. This versatility ensures long-term success in your drilling operations, regardless of conditions or requirements.

In addition to their adaptability to different rock formations and challenges, Teamwhole's DTH bits are also designed for maximum efficiency and productivity in drilling operations. The precision engineering of the bit head face designs and carbide shapes ensures that each bit delivers optimal performance, allowing for faster drilling speeds and reduced downtime. This means that you can complete your drilling projects more quickly and cost-effectively, ultimately contributing to the long-term success of your operations.

Unlocking Efficiency and Productivity in Drilling Operations

By choosing Teamwhole's DTH bits, you are unlocking efficiency and productivity in your drilling operations. Their superior performance across different industries makes them reliable for any project. With diameters ranging from 3 to 47 inches (76mm-1200mm), there's no doubt that Teamwhole has what it takes to tackle any downhole hammer challenge easily.

With a commitment to quality and innovation, Teamwhole's DTH bits are designed to deliver optimal performance and durability in drilling operations. Their advanced engineering and cutting-edge technology ensure that each bit can withstand the toughest drilling conditions, resulting in increased efficiency and productivity on the job site. Whether for mining, construction, or oil and gas exploration, Teamwhole's DTH bits are a game-changer in the industry.