Introduction

When it comes to deep well drilling, having the best rock hammer is crucial for success. A quality rock pick hammer can make all the difference in breaking through tough rock formations and ensuring a smooth drilling operation. With so many geologists hammers on the market, choosing the right one can be daunting. That's why it's important to consider several factors before selecting.

The Importance of a Quality Rock Hammer

Geologists and drilling professionals understand a top-tier rock hammer's crucial role in their work. The right tool facilitates drilling through challenging surfaces and enhances overall efficiency, saving valuable time and resources. A dependable geological hammer is undeniably a game-changer in geological exploration or construction endeavors.

- Precision and Durability: The best rock hammers are crafted with precision and built to last, ensuring they withstand the demands of rigorous fieldwork.

- Efficient Drilling: A quality rock pick enhances drilling efficiency, allowing professionals to navigate hard surfaces easily and quickly.

- Versatility in Applications: Whether engaged in geological studies or construction projects, a reliable rock hammer proves versatile, adapting to various tasks with optimal performance.

- Time and Resource Savings: Investing in a superior rock hammer translates to significant time and resource savings, making it a prudent choice for professionals in the field.

- Enhanced Fieldwork Experience: A top-notch geological hammer gets the job done and enhances the overall fieldwork experience, providing users with confidence and reliability.

The importance of a quality rock hammer cannot be overstated. It is an invaluable asset for professionals in geological exploration and construction, offering precision, durability, and efficiency, ultimately elevating the standards of their work.

Choosing the Right Rock Hammer for Deep Well Drilling

In deep well drilling, selecting a suitable rock hammer demands meticulous attention to key factors. To achieve optimal performance, considerations such as size, weight, and material composition play a pivotal role in making an informed choice. With a plethora of options available, it becomes imperative to pick a hammer tailored explicitly for deep well drilling applications.

- Size Matters: Opt for a rock hammer that aligns with the scale of your deep well drilling project. The right size ensures efficient handling and maneuverability in various drilling conditions.

- Weight Considerations: Strike a balance between the hammer's weight and the demands of deep well drilling. A well-chosen weight facilitates precision and control during the drilling process.

- Material Composition: The durability and resilience of the rock hammer depend on its material composition. Choose a hammer crafted from robust materials capable of withstanding the challenges posed by deep well drilling environments.

- Application Specificity: Ensure the selected rock hammer is explicitly designed for deep well drilling. Tailored features and specifications enhance its performance in this specialized application.

- User Comfort and Ergonomics: A comfortable grip and ergonomic design are essential for extended use. Prioritize hammers that minimize user fatigue and provide a comfortable drilling experience.

Selecting the right rock hammer for deep well drilling involves carefully evaluating size, weight, material composition, application specificity, and user comfort. Making a well-informed choice in these aspects ensures optimal performance and efficiency in demanding drilling scenarios.

Factors to Consider When Selecting a Rock Hammer

- Durability: Prioritize a rock hammer that boasts robust construction and durable materials. Durability ensures longevity, making the tool capable of withstanding the rigors of demanding geological or construction tasks.

- Impact Force: Assess the impact force of the rock hammer, as it directly influences its ability to break through hard surfaces efficiently. A high-impact force is crucial for tackling challenging drilling scenarios effectively.

- Compatibility with Drilling Equipment: Ensure seamless integration with your drilling equipment by selecting a rock hammer compatible with the machinery. Compatibility enhances overall performance and reduces the risk of operational issues.

- Types of Rock Hammers: Familiarize yourself with the various types available, such as hydraulic and pneumatic rock hammers. Understanding these distinctions lets you choose the type that best aligns with your specific drilling requirements.

- Application Versatility: Opt for a rock hammer that exhibits versatility in its applications. Whether geological exploration or construction projects, a versatile tool adapts to different tasks, making it a valuable asset in various scenarios.

- Ease of Maintenance: Consider the ease of maintenance and availability of replacement parts. A rock hammer with straightforward maintenance requirements ensures minimal downtime and long-term cost-effectiveness.

- User-Friendly Features: Use user-friendly features such as ergonomic handles and intuitive controls. These features enhance comfort during operation, reducing fatigue and increasing overall efficiency.

The quest for the best rock pick hammer involves evaluating factors such as durability, impact force, compatibility, types, application versatility, ease of maintenance, and user-friendly features. A comprehensive understanding of these aspects guides the selection process, leading to a tool that precisely meets your specific needs.

Understanding the Different Types of Rock Hammers

When it comes to rock hammers, there are two main types to consider: hydraulic and pneumatic. Hydraulic rock hammers are powered by a hydraulic system, making them ideal for heavy-duty drilling in tough terrains. On the other hand, pneumatic rock hammers rely on compressed air for operation, offering versatility and ease of use in various drilling applications.

Hydraulic vs. Pneumatic Rock Hammers

Hydraulic rock hammers are known for their exceptional power and efficiency, making them the best choice for deep well drilling and heavy-duty excavation projects. Their ability to deliver high-impact force makes them a top pick for geologists and professionals working in challenging geological conditions. On the other hand, pneumatic rock hammers are lighter and more portable, making them suitable for smaller-scale drilling tasks and fieldwork.

Top Features to Look for in a Rock Hammer

Selecting an optimal rock hammer requires a careful examination of essential features. Understanding these key elements is crucial whether you're tackling geological exploration or construction tasks. Below, discover the top features to prioritize when choosing a rock hammer for your specific drilling needs.

- Impact Energy: Prioritize a rock hammer with high-impact energy for efficient drilling through tough surfaces.

- Blow Frequency: Consider a well-balanced blow frequency for consistent and reliable performance in diverse drilling conditions.

- Durability of Components: Ensure the tool's components are durable to guarantee longevity and resilience in demanding work environments.

- Adjustable Settings: Look for a rock hammer with adjustable settings to tailor its performance to your project's requirements.

- Ergonomic Design: Choose a hammer with an ergonomic design and comfortable grip handles to reduce operator fatigue, especially during prolonged use.

- Ease of Maintenance and Repair: Opt for a rock hammer that is easy to disassemble and reassemble for quick maintenance or component replacement.

A rock hammer equipped with these top features ensures efficient drilling and contributes to the longevity and user comfort essential for successful project completion.

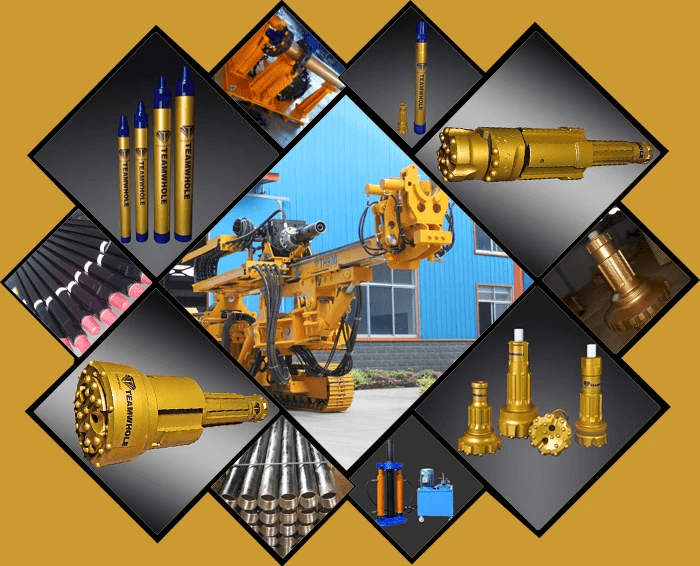

Benefits of Using a Tianhe Rock Hammer

Tianhe rock hammers are an excellent choice due to their innovative design, superior performance, and durability. These top-rated geologists' hammers offer precision control over impact energy levels, ensuring efficient drilling operations with minimal effort. With their advanced technology and reliable construction, Tianhe rock hammers provide unmatched reliability and longevity in demanding geological conditions.

Tianhe rock hammers are also designed with user comfort in mind, featuring ergonomic handles and lightweight materials to reduce strain during prolonged use. This attention to detail makes them the ideal choice for deep well drilling projects requiring extended operation periods. Additionally, these hammers' precision control allows for accurate and consistent drilling depths, ensuring reliable results with every use.

Finding the Best Rock Hammer for Deep Well Drilling

Top-Rated Rock Hammers on the Market

When it comes to finding the best rock hammer for deep well drilling, several top-rated options on the market have gained popularity among geologists and drilling professionals. Brands like Estwing, Fiskars, and Tianhe offer a wide range of rock hammers known for their durability, efficiency, and performance in challenging drilling environments.

Pros and Cons of Popular Rock Hammer Brands

Each popular rock hammer brand has its own pros and cons that should be carefully considered before making a purchase. For example, while Estwing rock hammers are known for their solid steel construction and comfortable grip, Fiskars offers lightweight yet durable options with shock-absorbing handles. Understanding these differences can help you decide based on your specific drilling needs.

When determining the right size and weight for your rock hammer, it's important to consider the type of rock you'll be working with. A lighter hammer may be sufficient for softer rocks, while harder rocks may require a heavier tool to break through effectively. Additionally, the size of the hammerhead can impact the force and precision of your strikes, so be sure to choose a size that aligns with your specific drilling needs.

How to Determine the Right Size and Weight for Your Needs

When selecting a rock hammer for deep well drilling, finding the optimal size and weight is paramount for efficient and comfortable use. Here's a guide on how to make the right choice:

- Consider Your Physical Strength: Assess your own physical strength and endurance levels. A rock hammer that aligns with your strength ensures prolonged use without unnecessary strain.

- Type of Rocks You'll Encounter: Understand the geological composition of the rocks you'll be drilling. A lighter hammer may suffice for softer rocks, while harder rocks may require a heavier tool for effective drilling.

- Balance Between Comfort and Impact Force: Avoid extremes in size and weight. A geologist hammer that is too heavy can lead to discomfort and fatigue during extended use, while one that is too light may lack the necessary impact force for effective drilling.

- Trial and Error: If possible, try different sizes and weights to find the one that feels comfortable and provides the required impact force. Consider the ergonomic design of the hammer and how well it fits into your hand.

- Project-Specific Considerations: Tailor your choice based on the specifics of your deep well drilling project. The depth, density, and composition of the rocks you'll encounter should influence your decision.

Determining the right size and weight for your rock hammer involves a thoughtful assessment of your physical capabilities, the geological characteristics of the rocks, and the specific requirements of your deep well drilling project. Striking a balance ensures both efficiency and comfort throughout your drilling endeavors.

By exploring top-rated rock hammers on the market, weighing the pros and cons of popular brands, and determining the right size and weight for your needs, you can confidently choose the best rock hammer for successful deep well drilling projects.

Tips for Maintaining Your Rock Hammer

1. Proper Cleaning and Storage Techniques

To keep your best rock hammer in top condition, cleaning it after each use is important. Use a wire brush to remove dirt or debris from the head and handle, then wipe it down with a damp cloth. Store your rock hammer in a dry place to prevent rust and corrosion, and consider using a protective cover to keep it safe during transportation.

After cleaning and storing your rock hammer, it's important to inspect it regularly for any signs of wear or damage. Check the head and handle for any cracks, chips, or loose parts affecting its performance. If you notice any issues, take the time to repair or replace the necessary components to ensure your rock hammer continues to work effectively. By staying on top of inspections and maintenance, you'll be able to catch any potential problems early on and keep your rock hammer in top condition for years to come.

2. Regular Inspections and Maintenance Schedule

Regular inspections are crucial for ensuring the longevity of your rock hammer. Check for any signs of wear or damage, such as chipped edges or loose handles, and address them promptly. Establishing a maintenance schedule can help you stay on top of routine tasks like sharpening the head and tightening screws, ensuring that your rock hammer is always ready for action.

Regular inspections are crucial for ensuring the longevity of your rock hammer. Check for any signs of wear or damage, such as chipped edges or loose handles, and address them promptly. Establishing a maintenance schedule can help you stay on top of routine tasks like sharpening the head and tightening screws, ensuring that your rock hammer is always ready for action.

3. Extending the Lifespan of Your Rock Hammer

To extend the lifespan of your best rock hammer, take proactive measures to prevent unnecessary wear and tear. Avoid using excessive force when striking rocks, as this can lead to premature damage. Additionally, store your rock hammer in a secure location when not in use, protecting it from potential accidents or theft.

Remember that proper maintenance is key to getting the most out of your best rock hammer investment!

Safety Precautions When Using a Rock Hammer

Importance of Proper Training and Certification

It is crucial to undergo proper training and certification before using a rock hammer, as this tool requires skill and knowledge to operate safely. Geologists' hammers are powerful and can cause serious injury if not handled correctly, so being well-trained is essential.

Geologists hammers are powerful and can cause serious injury if not handled correctly, so being well-trained is essential. Proper training and certification will teach you how to safely handle the rock hammer and recognize potential hazards in the field. By understanding the risks associated with using a rock hammer, you can take proactive measures to mitigate those risks and ensure a safe working environment for yourself and others.

Potential Hazards and How to Mitigate Risks

Potential hazards when using a rock hammer include flying debris, hand-arm vibration syndrome, and musculoskeletal disorders. Always wear appropriate personal protective equipment such as safety goggles, gloves, and ear protection to mitigate these risks. Additionally, take regular breaks to reduce the risk of vibration-related injuries.

To further mitigate the risk of flying debris, inspecting the rock hammer regularly for any signs of wear or damage is important. This can help prevent the tool from malfunctioning and causing debris to fly in unexpected directions. Additionally, always ensure a clear and safe work area around you when using the rock hammer to minimize the potential impact of flying debris on yourself and others.

Ensuring a Safe and Efficient Drilling Operation

To ensure a safe and efficient drilling operation with your best rock hammer, always inspect the tool before use to check for any signs of wear or damage. It's also important to follow proper drilling procedures and techniques to minimize the risk of accidents or injury on the job site.

Safety is always the top priority when using a rock pick hammer for deep well drilling. By following these precautions and best practices, you can ensure a safe working environment while maximizing the performance of your rock hammer.

Tianhe: The Top Choice for Rock Hammers

When purchasing the best rock hammer for deep well drilling, making an informed decision is crucial. Consider factors such as the type of rock hammer, its top features, and the benefits of using a Tianhe rock hammer. By maximizing performance and durability through proper maintenance, you can ensure that your investment lasts for years. And with Tianhe standing out as the top choice for rock hammers, you can trust in their quality and reliability.

Making an Informed Decision for Your Rock Hammer Purchase

Choosing the best rock hammer involves careful consideration of your drilling needs and the specific features of each option available on the market. Whether you're looking for a geologist hammer or a pick hammer, it's important to weigh the pros and cons of each type before making a purchase. By doing thorough research and seeking expert advice, you can make a well-informed decision that meets your requirements.

Maximizing Performance and Durability with the Right Maintenance

Regular maintenance is key to ensuring that your rock hammer continues to perform at its best. Proper cleaning and storage techniques, regular inspections, and maintenance schedules can help extend its lifespan significantly. By taking care of your geological hammer or rock pick hammer, you can maximize its performance and durability over time.

Tianhe has established itself as a leading provider of high-quality rock hammers that cater to various drilling needs. With its top-rated products and commitment to safety and efficiency in drilling operations, Tianhe stands out as the top choice for those searching for the best rock hammers.

Tianhe's rock hammers are designed with durability and longevity, ensuring they can withstand the toughest drilling conditions without compromising performance. The use of high-quality materials and advanced engineering techniques sets Tianhe's rock hammers apart from the competition, making them a reliable choice for professionals in the drilling industry. Tianhe's rock hammers deliver consistent results and exceptional value for mining, construction, or geological exploration.