Introduction

When it comes to completing industrial projects, having the right blasting tools is crucial for achieving optimal results. Whether you're considering a blasthole drill, DTH hammers, sand blasting tools, or other industrial blasting equipment, understanding the different types available is essential for making informed decisions. Factors such as project requirements, environmental impact, and budgeting play a significant role in choosing the right tools for the job.

Different Types of Blasting Tools

Selecting the most suitable blasting tool for your project requires understanding the various options available. Here are some common types of blasting tools, each serving a specific purpose:

- Blasthole Drills: Designed to create precise holes for explosives placement, these drills are ideal for controlled blasting applications.

- DTH Hammers (Down-The-Hole): Delivering high-impact energy, DTH hammers efficiently break rock formations, making them suitable for large-scale excavation projects.

- Pneumatic Breakers: Portable and powerful, these handheld tools are used for smaller demolition jobs and breaking through concrete or rock.

- Explosive Initiators and Detonators: These tools initiate the detonation of explosives and require specific training and permits for safe handling.

- Blasting Accessories: This category encompasses various tools, such as stemming plugs, blasting mats, and delay timers, which are crucial for safe and efficient blasting operations.

Remember, choosing the right blasting tool involves considering factors like material hardness, project size, precision needs, portability, maintenance, and cost. Make an informed decision by carefully evaluating these factors and ensure you adhere to all safety regulations and permit requirements when using blasting tools.

Factors to Consider When Choosing Blasting Tools

Choosing the right blasting tools is crucial for ensuring the efficiency and effectiveness of your project. Here are some key factors to consider:

- Size and type of blasthole drill: The drill you choose must create holes of the appropriate size and depth for your specific project. Different types of drills are available, each with its own capabilities and limitations.

- DTH hammer efficiency: Down-The-Hole (DTH) hammers significantly impact drilling speed and productivity. Consider the efficiency of different DTH hammers available for your project.

- Abrasive material (sand blasting): The abrasive material used in sand blasting significantly impacts the cleaning process. Choose the appropriate abrasive based on the cleaned material and the desired outcome.

By carefully considering these factors, you can choose the blasting tools best suited for your project's specific needs, ensuring a successful and efficient operation.

Importance of Using the Right Blasting Tools

Choosing the appropriate blasting tools is essential for any industrial project, impacting not only its success (1) but also its efficiency (2) and safety (3).

- Meeting Project Requirements: Durable and high-performance equipment, like DTH bits and drills, is crucial to tackle specific project demands.

- Maximizing Efficiency and Accuracy: Utilizing high-quality tools ensures precise blasting, achieving desired outcomes without sacrificing efficiency.

- Enhancing Safety and Reducing Costs: Investing in the right equipment minimizes downtime and maintenance needs, ultimately leading to long-term cost savings.

By carefully selecting the appropriate blasting tools, industrial projects can be completed successfully, efficiently, and safely, while minimizing environmental impact and maximizing cost-effectiveness.

Exploring the Options

When it comes to exploring the options for blasting tools, it's essential to consider the specific needs of your project. The blasthole drill is a crucial tool in mining and construction, and choosing the right size and type can greatly impact efficiency and productivity. On the other hand, DTH hammers play a key role in rock drilling operations, so understanding their impact on efficiency is vital. And when it comes to sand blasting tools, finding the right abrasive material is essential for achieving the desired surface finish.

Blasthole Drill: Choosing the Right Size and Type

The blasthole drill is a versatile tool used in various industries, including mining, construction, and quarrying. When selecting a blasthole drill, it's important to consider factors such as hole diameter, depth of drilling, and type of material being drilled. The size and type of blasthole drill you choose will directly impact the efficiency and effectiveness of your drilling operations.

When choosing a blasthole drill, it's crucial to consider the specific requirements of your drilling project. For example, if you're working in a tight space or need to drill smaller diameter holes, a compact blasthole drill may be the best option. On the other hand, if you're drilling large-diameter blastholes for mining or quarrying purposes, a larger and more powerful drill would be more suitable. Understanding the unique needs of your project will help you select the right size and type of blasthole drill for optimal efficiency and effectiveness.

DTH Hammers: Understanding the Impact on Efficiency

DTH hammers are integral to down-the-hole drilling operations and are designed to deliver maximum power and efficiency. Understanding how different types of DTH hammers impact efficiency is crucial for achieving optimal results in rock drilling projects. Factors such as hammer size, air pressure requirements, and drilling speed all play a significant role in determining overall efficiency.

When it comes to DTH hammers, the size of the hammer is a crucial factor in determining efficiency. Larger hammers can deliver more power, allowing for faster and more effective drilling. However, it's important to consider the specific requirements of each drilling project to determine the most suitable hammer size. Operators can maximize efficiency and achieve optimal results by selecting the right hammer size for the job.

Sand Blasting Tools: Finding the Right Abrasive Material

Sand blasting tools are commonly used for surface preparation in automotive, aerospace, and manufacturing industries. Choosing the right abrasive material is essential for achieving the desired surface finish while minimizing material waste. Factors such as hardness, particle size distribution, and shape contribute to finding the most suitable abrasive material for sand blasting applications.

Remember that choosing the right blasting tools is crucial for maximizing efficiency and effectiveness in your projects. Whether you're considering blasthole drills, DTH hammers or sand blasting tools - each tool plays a critical role in achieving successful outcomes in industrial applications.

Evaluating Industrial Blasting Equipment

Commercial Blasting: Meeting the Specific Needs of Your Project

When it comes to commercial blasting, it's crucial to choose the right blasting tools that cater to the specific requirements of your project. Whether you need a blasthole drill for large-scale mining operations or sand blasting tools for surface preparation, selecting the appropriate equipment is essential for achieving optimal results.

Choosing the right blasting tools also involves considering the project's environmental impact. Opting for eco-friendly blasting solutions can help minimize the release of harmful emissions and reduce the overall carbon footprint. Additionally, selecting equipment with advanced dust suppression technology can contribute to a safer and healthier work environment for your team. By prioritizing sustainability and safety in your blasting tool selection, you can ensure that your project meets industry regulations and standards.

DTH Bit: Ensuring Durability and Performance

The durability and performance of DTH bits are paramount in industrial blasting operations. With many options available, it's important to carefully evaluate factors such as material composition, bit design, and compatibility with different drilling conditions. Ensuring the longevity and effectiveness of your blasting tools is key to maximizing productivity.

When evaluating the material composition of DTH bits, it's crucial to consider factors such as hardness, toughness, and resistance to wear and tear. Different drilling conditions require different material properties to ensure optimal performance and longevity. By carefully selecting DTH bits with the right material composition, you can minimize downtime and maintenance costs while maximizing productivity in industrial blasting operations.

DTH Drill: Selecting the Right Tool for the Job

Selecting the right DTH drill involves considering hole diameter, drilling depth, rock hardness, and required penetration rates. Whether you're working in construction, quarrying, or civil engineering projects, choosing a DTH hammer that meets your specific drilling needs can significantly impact operational efficiency and cost-effectiveness. Additionally, it's essential to factor in the type of material being drilled, as different hammers are designed to handle various rock formations. Furthermore, considering the environmental conditions of the drilling site is crucial to ensure that the chosen DTH drill can withstand any challenges posed by extreme weather or terrain.

Key Considerations for Selection

When assessing the project requirements for blasting tools, it's crucial to consider the type of material being blasted, the size of the area, and the desired finish. For example, a blasthole drill may be more suitable for large-scale mining projects, while sand blasting tools are ideal for surface preparation and cleaning. Understanding these specific needs will help make an informed decision when selecting the right tool.

Assessing the Project Requirements

Before choosing between blasthole drill, dth hammers, or sand blasting tools, it's important to evaluate the specific requirements of your project. Consider factors such as material hardness, depth of drilling or blasting, and environmental conditions. By understanding these needs thoroughly, you can ensure that you select the most appropriate blasting tools for your project.

After evaluating the specific requirements of your project, it's also important to consider the potential environmental impact and safety implications of your blasting tools. Different methods of drilling or blasting may have varying levels of impact on the surrounding environment, so it's crucial to choose tools that minimize harm. Safety should always be a top priority when selecting equipment, as certain tools may pose greater risks to workers or nearby communities. By carefully weighing these factors, you can make a more informed decision that aligns with your project's needs and values.

Considering Environmental Impact and Safety

Environmental impact and safety should always be top priorities when selecting industrial blasting equipment. DTH hammers and drills must meet industry standards to minimize environmental impact and ensure worker safety. Sand blasting tools should also use environmentally friendly abrasive materials to reduce harmful emissions and protect workers from potential health hazards.

When budgeting for industrial blasting equipment, it's important to prioritize quality and longevity. While investing in high-quality DTH hammers and drills may require a larger initial investment, they will ultimately save money in the long run by reducing maintenance costs and downtime. By choosing durable equipment, businesses can ensure that their operations run smoothly and efficiently without the need for frequent replacements.

Budgeting for Quality and Longevity

While cost is a significant factor in choosing commercial blasting equipment such as DTH bit or dth drill, it's essential to prioritize quality and longevity over upfront expenses. Investing in high-quality blasting tools may require a larger budget initially, but it can save money in the long run by reducing maintenance costs and improving efficiency.

With these key considerations, you can confidently select the most suitable blasting tools for your specific project needs while prioritizing environmental impact, safety, quality, and longevity.

Remember that making an informed decision when choosing Tianhe for reliable and innovative blasting tools will maximize efficiency and effectiveness on your project!

Choose Tianhe for Reliable and Innovative Blasting Tools

When selecting the right blasting tools for your project, making an informed decision is crucial based on the specific requirements and environmental impact. With options like blasthole drills, DTH hammers, and sand blasting tools, it's important to choose a reliable and innovative provider like Tianhe to ensure maximum efficiency and effectiveness.

Making an Informed Decision for Your Project

Understanding the different types of blasting tools, evaluating industrial blasting equipment, and considering factors like project requirements, environmental impact, and budget are all essential in making an informed decision for your project. Careful consideration is key whether you need a blasthole drill for mining or sand blasting tools for surface preparation.

After carefully evaluating the different types of blasting tools and considering factors like project requirements, environmental impact, and budget, it is important to choose a reliable and innovative brand for your blasting equipment. Tianhe offers a wide range of blasting tools known for their quality and durability. With a focus on customer satisfaction and continuous improvement, Tianhe is a trusted choice for all your blasting needs.

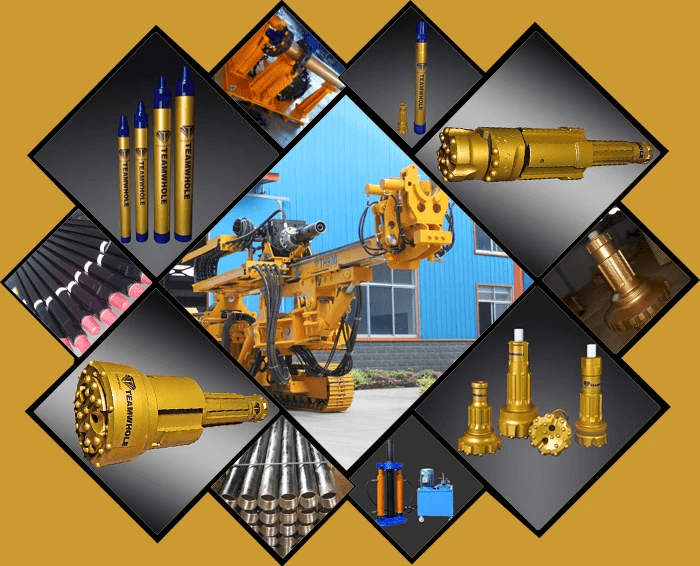

Tianhe offers various reliable and innovative blasting tools such as DTH hammers, commercial blasting equipment, DTH bits, and DTH drills. With their commitment to quality and durability, choosing Tianhe ensures you have the right tools to stand the test of time.

Maximizing Efficiency and Effectiveness with the Right Tools

By selecting the right blasting tools from Tianhe, you can maximize efficiency and effectiveness in your projects. Whether achieving precise blasthole drilling or ensuring optimal performance with DTH hammers, having the right tools can make all the difference in achieving successful outcomes.

Having the right blasting tools is crucial when completing projects on time and within budget. With Tianhe's high-quality equipment, you can ensure that your blasthole drilling is precise and efficient, saving time and resources. Additionally, their DTH hammers are designed for optimal performance, allowing you to achieve the desired results easily. Investing in the right tools from Tianhe can set your projects up for success.