Introduction

When it comes to water well drilling, understanding your specific needs is crucial. Whether you're looking to drill a new well or maintain an existing one, selecting the right rig is essential for a successful project. Exploring different types of drilling rigs and considering top factors will help you make an informed decision.

Understanding Your Water Well Drilling Needs

Before diving into the world of drill rigs, it's important to assess your water well drilling needs. Consider factors such as the depth and diameter of the well, the type of soil or rock formations in your area, and any specialized applications you may have in mind. Understanding these requirements will guide you in selecting the most suitable rig for your project.

Top Considerations for Selecting the Right Rig

When choosing a water well drilling rig, it's crucial to weigh various considerations such as cost, efficiency, and versatility. For instance, comparing top hammer drilling rigs versus DTH (Down-The-Hole) drilling rigs can help you determine which type aligns best with your specific needs and budget. Additionally, evaluating the overall performance and adaptability of different drill rigs is key in making an informed decision.

Exploring Different Types of Drilling Rigs

Drill rigs come in various types designed for specific applications such as mining, micropile installations, and water well drilling. Each type offers unique features and capabilities tailored to different projects. By exploring these options thoroughly, you can gain a better understanding of which drill rig will best suit your water well drilling needs.

Examining Water Well Drilling Rig Types

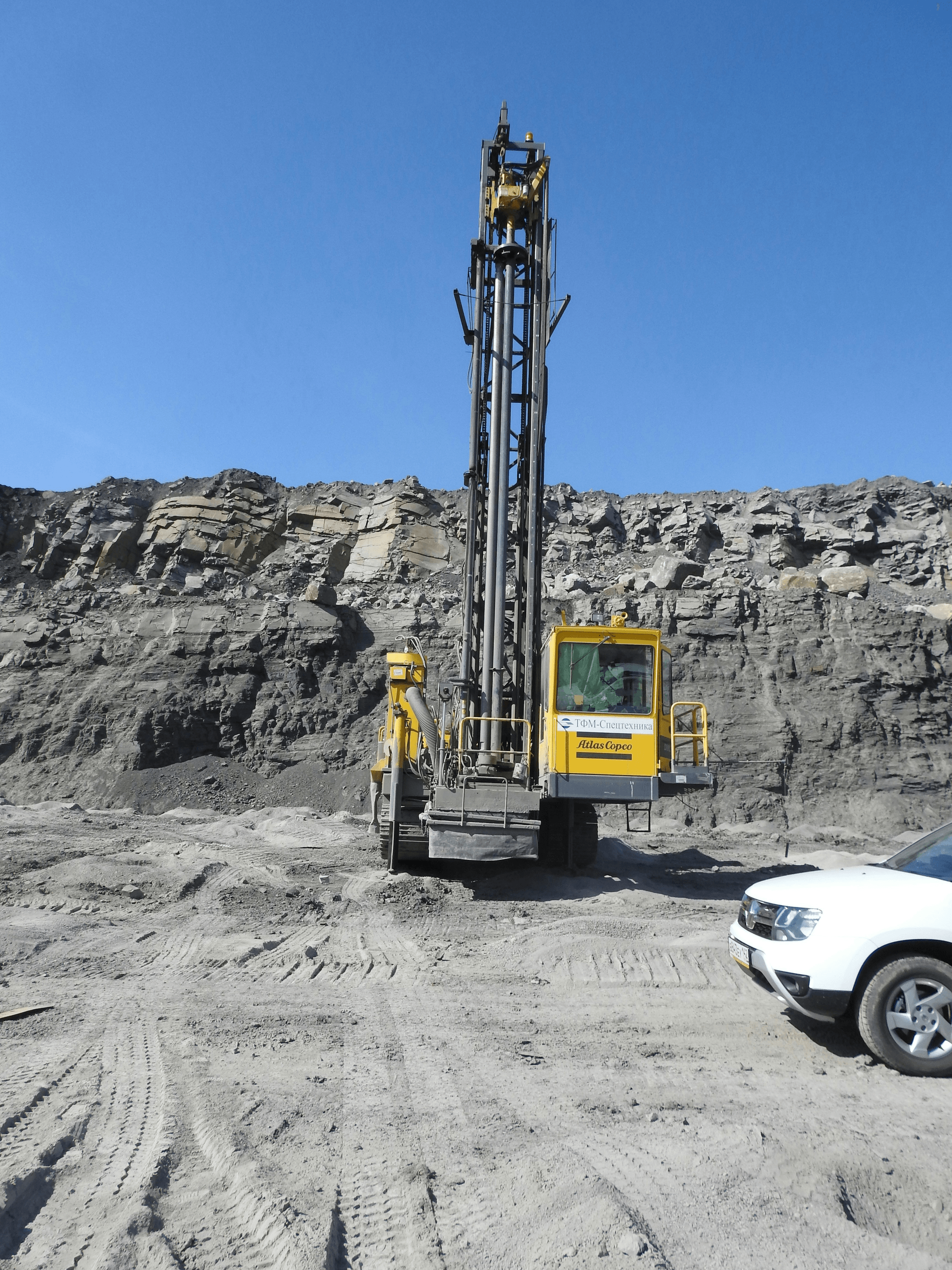

When it comes to selecting the right water well drilling rig, understanding the differences between a top hammer drilling rig and a DTH drilling rig is crucial. The top hammer rig is ideal for shallow holes and softer rock formations, while the DTH rig is better suited for deeper wells and harder rock. Considering the specific geological conditions of your drilling site will help you make an informed decision on which type of rig to use.

Top Hammer Drilling Rig VS DTH Drilling Rig

The top hammer drilling rig operates by using a percussive force to break the rock, making it suitable for smaller diameter holes at shallower depths. On the other hand, the DTH drilling rig uses air pressure to drive the drill bit into the rock, allowing for deeper and larger diameter holes. Understanding the differences in their operational mechanisms will help you choose the most efficient option for your water well drilling needs.

The top hammer drilling rig is ideal for projects that require smaller diameter holes at shallower depths, such as water well drilling or foundation work. Its percussive force efficiently breaks through rock and soil, making it a cost-effective option for these types of applications. On the other hand, the DTH drilling rig is better suited for larger diameter holes and deeper depths, making it a more suitable choice for mining or geothermal drilling projects.

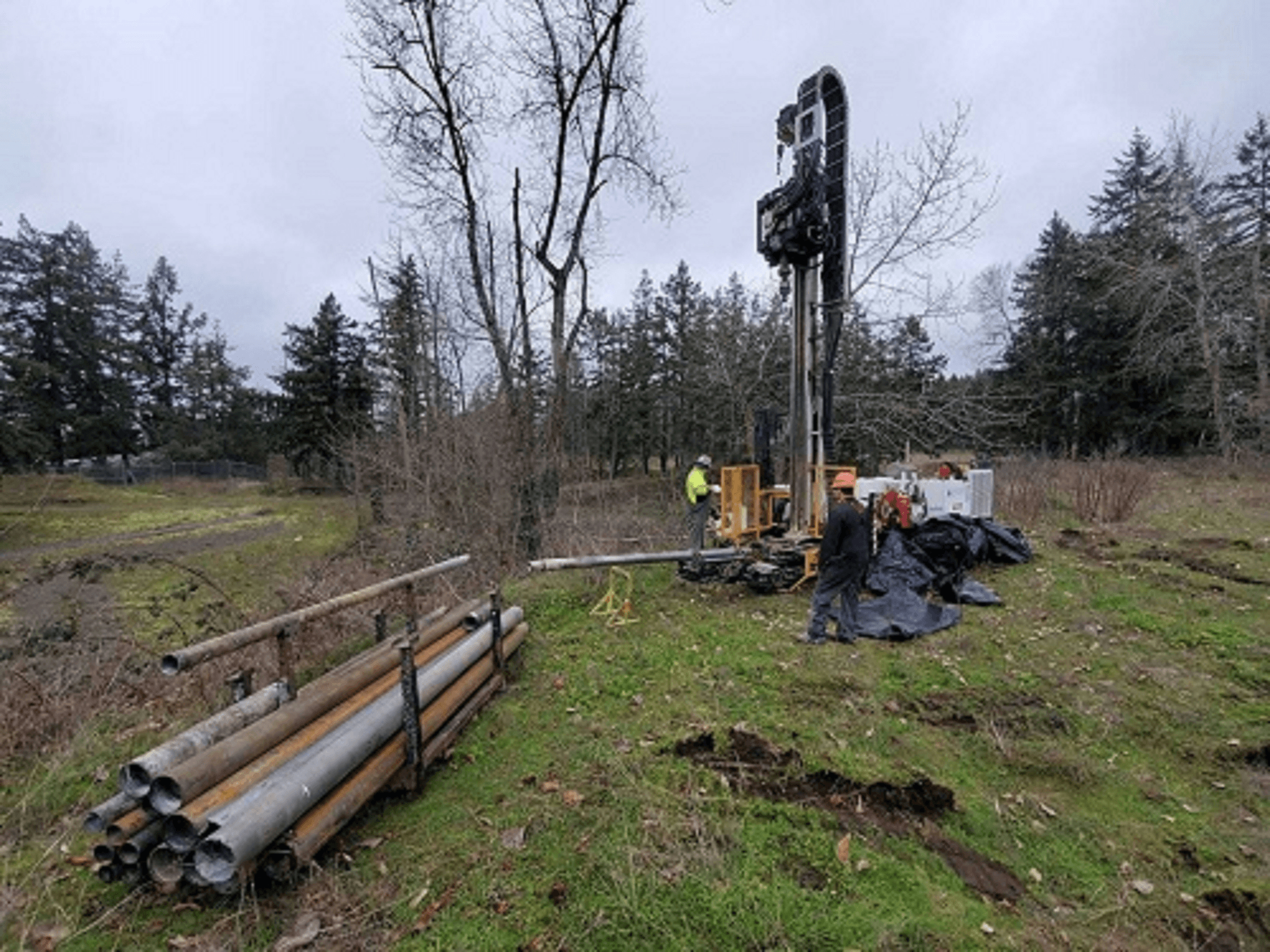

Micropile Drill Rig for Specialized Applications

For specialized applications that require precise and controlled drilling, a micropile drill rig is essential. This type of drill rig is commonly used in construction projects where limited access or environmental constraints are present. Its compact size and ability to operate in confined spaces make it an invaluable tool for challenging drilling scenarios.

In addition to its compact size and ability to operate in confined spaces, a micropile drill rig offers versatility in terms of drilling capabilities. It can be used for a wide range of drilling applications, including soil nailing, rock anchoring, and foundation underpinning. This versatility makes it a cost-effective solution for construction projects that require different types of drilling within the same site. The ability to switch between drilling methods without the need for additional equipment or extensive setup time adds to the efficiency and practicality of using a micropile drill rig.

Evaluating the Versatility of Drill Rigs

When evaluating different types of drill rigs, it's important to consider their versatility in handling various geological conditions and project requirements. Some rigs may offer customizable features that allow for easy modification based on specific needs, while others may excel in efficiency and precision. Understanding how versatile a drill rig is can significantly impact its performance across different applications.

Can I use a hammer drill as a regular drill? While both tools share similarities in appearance, a hammer drill is specifically designed for masonry work such as concrete or brick drilling due to its ability to create rapid forward thrusts combined with rotary motion. This makes it unsuitable for regular woodworking or metalworking tasks where precision control is needed.

What is the hammer drill used for? The hammer drill's primary purpose lies in its ability to efficiently bore through hard materials like concrete or stone by delivering rapid impacts from behind the bit as it rotates. This unique functionality makes it an indispensable tool in construction projects that require precise hole-making capabilities in tough surfaces.

Remember when selecting your water well drilling rig, understanding your specific needs and considering factors such as geological conditions, project requirements, and versatility are key elements that will guide you towards making an informed decision on which type of drill rig will best suit your needs!

Key Features to Look For

When selecting a water well drilling rig, it's crucial to consider the efficiency and precision of the mining drilling rig. Look for a rig that can handle tough conditions and deliver accurate results, ensuring that your water well is drilled with the highest quality standards in mind.

Efficiency and Precision in Mining Drilling Rig

Efficiency and precision are key features to look for in a mining drilling rig. A top hammer drilling rig offers high penetration rates and excellent hole straightness, making it ideal for various applications including water well drilling. With advanced technology and reliable performance, this type of rig ensures that your drilling operations are carried out with maximum efficiency and precision.

In addition to high penetration rates and excellent hole straightness, low air consumption is another crucial factor to consider when selecting a mining drilling rig. A top hammer drilling rig with low air consumption can significantly reduce operating costs and environmental impact, making it a more sustainable choice for your drilling operations. By minimizing the amount of compressed air required, this type of rig maximizes efficiency and precision while also promoting responsible resource usage.

The Importance of Low Air Consumption in a Drill Rig

Low air consumption is another essential feature to consider when selecting a drill rig for water well drilling. A DTH drilling rig with low air consumption helps minimize energy usage while maintaining high productivity, making it a cost-effective choice for your water well drilling needs. This feature ensures that you can complete your projects efficiently without compromising on performance.

In addition to minimizing energy usage and maintaining high productivity, a DTH drilling rig with low air consumption also reduces the environmental impact of your water well drilling projects. By using less air, you can decrease the emissions generated during the drilling process, contributing to a more sustainable and eco-friendly operation. This makes low air consumption an important consideration for companies looking to minimize their carbon footprint and adhere to environmental regulations.

Customizable Features for Tailored Solutions

Look for customizable features in a drill rig to ensure that it meets your specific requirements for water well drilling. Whether it's adjustable feed force, rotary speed control, or advanced monitoring systems, having customizable features allows you to tailor the rig to match the unique demands of your water well project. This flexibility ensures that you can achieve optimal results while adapting to different geological conditions.

Understanding the Advantages

When it comes to selecting a water well drilling rig, it's crucial to consider the advantages that each type offers. A reliable structure and easy maintenance are key factors to look for in a drill rig, ensuring smooth operation and minimal downtime for repairs. Additionally, enhancing durability with customized DTH bit steel can significantly extend the lifespan of the rig, saving both time and money in the long run.

Reliable Structure and Easy Maintenance

A water well drilling rig with a reliable structure is essential for handling the demanding conditions of drilling operations. Look for rigs constructed with high-quality materials and sturdy components to ensure longevity and durability. Easy maintenance features such as accessible parts and user-friendly design can greatly reduce downtime and keep your drilling operations running smoothly.

When it comes to ensuring the reliability and longevity of a water well drilling rig, customized DTH bit steel can make a significant difference. By using high-quality steel that is tailored to the specific needs of your drilling operations, you can enhance the durability and performance of your rig. Customized DTH bit steel is designed to withstand the tough conditions of drilling, providing greater resistance to wear and tear while maintaining optimal drilling efficiency.

Enhancing Durability with Customized DTH Bit Steel

Customized DTH bit steel is an excellent way to enhance the durability of your water well drilling rig. By using specialized steel materials tailored to your specific drilling needs, you can increase the resistance to wear and tear, ultimately extending the life of your drill bits. This not only improves efficiency but also reduces replacement costs over time.

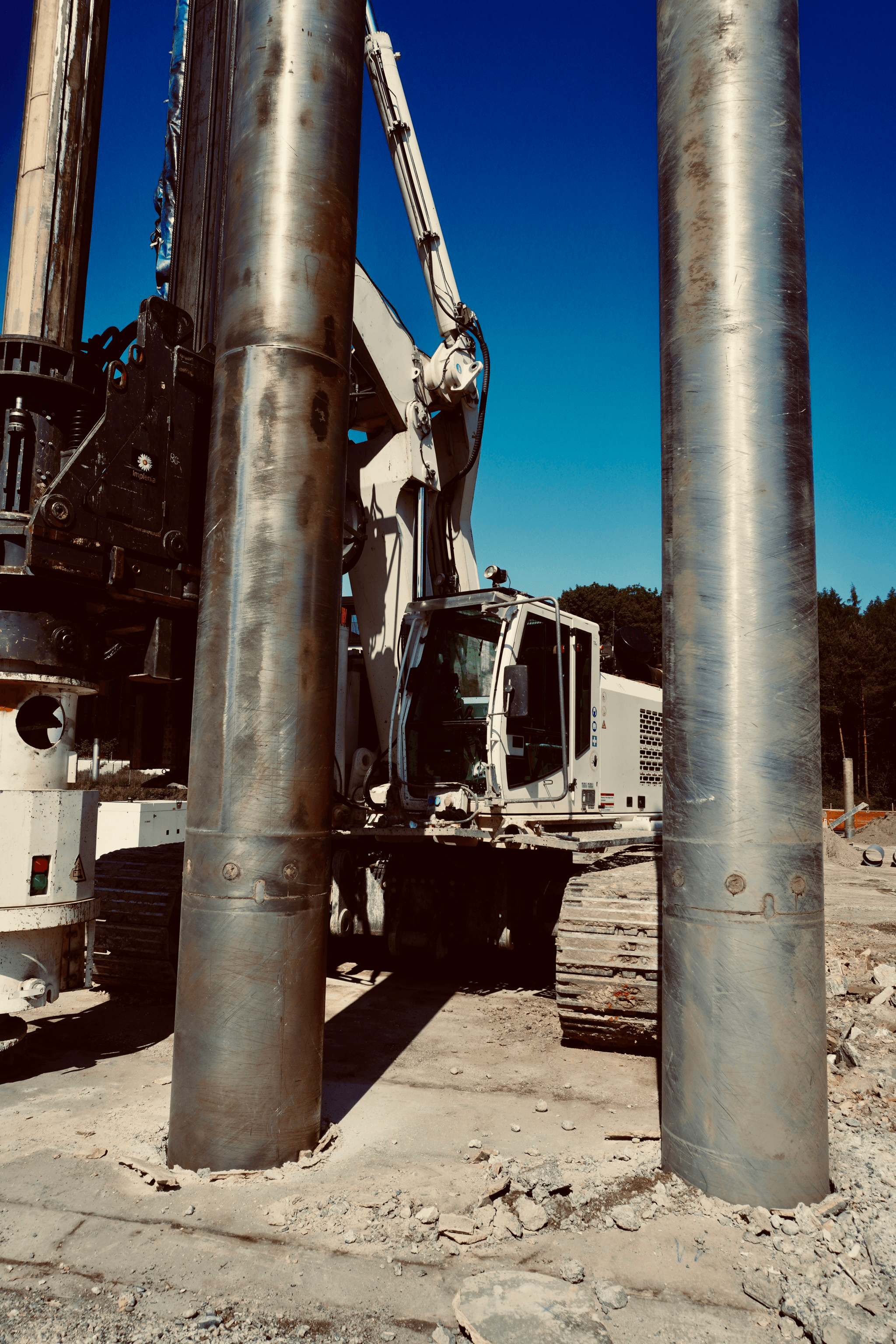

Flexibility and Easy Modification with Stabilizer Position

Another advantage to look for in a water well drilling rig is flexibility through stabilizer position modification. This feature allows you to adapt the rig to different types of terrain or specific drilling requirements, providing versatility in various applications. The ability to easily modify stabilizer positions can make a significant difference in achieving optimal results for each project.

Conclusion

When selecting a water well drilling rig, it's crucial to consider factors such as the type of drilling rig, efficiency, and customizable features. Understanding the differences between top hammer drilling rigs and DTH drilling rigs is essential for making an informed decision. It's also important to explore the applications and benefits of a hammer drill to determine if it can be used as a regular drill.

How to Select Water Well Drilling Rig

Selecting the right water well drilling rig involves assessing your specific drilling needs, evaluating different types of rigs available, and considering key features like efficiency and precision. By understanding these factors, you can make an informed decision that meets your requirements for water well drilling.

After evaluating different types of rigs available, it's important to consider the specific features that will best suit your drilling needs. For example, if you require a rig for drilling in remote or difficult-to-access locations, portability and ease of transportation may be key factors to consider. On the other hand, if you are drilling in areas with challenging geological conditions, you may prioritize rigs with advanced drilling capabilities and durability.

Can a Hammer Drill Be Used as a Regular Drill?

While a hammer drill can be used for regular drilling tasks, it may not provide the precision and control that a traditional drill offers. The hammering action of a hammer drill can cause the bit to wander, making it difficult to create clean, accurate holes in softer materials like wood or plastic. Additionally, the added weight and bulk of a hammer drill may make it less comfortable to use for extended periods of time, especially for tasks that require finesse and attention to detail.

Applications and Benefits of the Hammer Drill

The hammer drill is commonly used in construction and renovation projects for its ability to tackle tough materials like concrete and stone. Its impact mechanism allows for more efficient drilling in hard surfaces, making it a valuable tool in various industries where precision and power are required.

The hammer drill's versatility extends beyond just construction and renovation projects. It is also commonly used in mining and quarrying operations, where it can easily bore through tough rock formations. Additionally, the hammer drill is a popular choice for installing electrical and plumbing systems in existing structures, as it can quickly and efficiently create holes for wiring and piping. Its ability to handle a wide range of materials makes it an indispensable tool in various industries, from infrastructure development to interior design.