Introduction

Are you familiar with DTH drilling and rotary drilling methods? These two techniques are vital in the field of construction and mining. Choosing the right method can make a significant difference in the success of your project. Let's explore these drilling methods to understand their advantages and limitations.

Understanding DTH Drilling

DTH drilling, or Down-the-Hole hammer drilling, is a method used to drill boreholes through rocks. It involves a pneumatic hammer that delivers powerful blows to the drill bit, allowing for efficient penetration into hard surfaces. This method is widely used in mining, quarrying, and construction industries due to its speed and precision.

DTH drilling is known for its ability to provide accurate and clean boreholes, making it a preferred method in the construction industry. The pneumatic hammer delivers precise blows to the drill bit, resulting in minimal deviation from the desired drilling path. This level of accuracy is crucial when creating foundations for buildings or installing support structures.

Exploring Rotary Drilling

On the other hand, rotary drilling involves a rotating drill bit that cuts through rock formations. While it is versatile and can reach great depths, it may not be as efficient in hard rock formations as DTH drilling. Understanding the differences between these methods is crucial for selecting the most suitable one for your project.

Rotary drilling is also known for its ability to handle a wide range of hole sizes, making it a popular choice for various projects. However, it is important to consider the potential challenges that may arise when using this method, such as the risk of deviation in the borehole path. This can lead to inaccuracies and inefficiencies, particularly in complex geological formations. Therefore, careful planning and monitoring are essential to ensure the success of a rotary drilling project.

The Importance of Choosing the Right Method

The decision between DTH hammer drilling and rotary drilling should not be taken lightly. Factors such as rock hardness, depth of the borehole, and project timeline must be considered when choosing the appropriate method. Making an informed decision will ensure optimal results for your project.

Choosing the right drilling method is crucial for the success of your project. DTH hammer drilling is ideal for hard rock formations, while rotary drilling is better suited for softer materials. Considering the rock hardness will help you determine which method will be most effective in achieving the desired borehole depth. Additionally, taking into account the project timeline will ensure that you select a method that can deliver results within your timeframe.

What is DTH Drilling?

How DTH Drilling Works

DTH drilling, or Down-the-Hole drilling, is a method where the hammer is located at the bottom of the hole and strikes the drill bit directly. Compressed air powers the hammer, which in turn breaks the rock into small chips. The drill cuttings are then removed by blowing air down the hole.

Advantages of DTH Drilling

One major advantage of DTH drilling is its ability to drill through hard rock formations with ease and efficiency. It also provides a straighter hole, making it ideal for precise drilling operations. Additionally, DTH drilling allows for faster penetration rates compared to other methods.

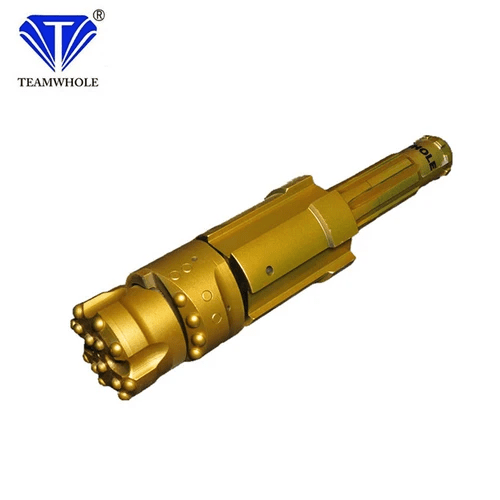

TEAMWHOLE's Efficient DTH Hammers

TEAMWHOLE offers a range of efficient and durable DTH hammers that are designed to maximize productivity and minimize downtime. Their hammers are engineered with advanced technology to deliver high performance in various drilling applications, making them a reliable choice for any project.

Now you have an understanding of how DTH drilling works and its advantages as well as TEAMWHOLE's efficient DTH hammers. Let's move on to exploring rotary drilling and its differences from the down-the-hole method.

Understanding Rotary Drilling

The Rotary Drilling Process

Rotary drilling involves the use of a sharp, rotating drill bit to create cylindrical holes in the earth's surface. This process is commonly used for oil and gas exploration, as well as for creating wells and boreholes. The drill bit is attached to a rotating drill string, which allows for deeper and more precise drilling compared to other methods.

Advantages and Limitations of Rotary Drilling

One advantage of rotary drilling is its ability to reach deeper depths than other drilling methods, making it ideal for oil and gas exploration. However, one limitation is that it can be more expensive and time-consuming due to the need for specialized equipment and skilled operators. Additionally, rotary drilling may not be suitable for certain geological formations or environmental conditions.

Differences in Equipment for Rotary Drilling

The equipment used in rotary drilling includes a rotary table, drill string, hoisting equipment, and a mud circulation system. These components work together to facilitate the drilling process by providing power to the drill bit, removing cuttings from the hole, and maintaining stability during operation. Compared to DTH hammer drilling tools, rotary drilling equipment is larger and more complex.

By using both DTH hammer drilling tools and rotary drilling methods effectively, you can ensure that your project will be completed efficiently while meeting safety standards and budget requirements.

DTH Rock Drilling Hammers

DTH Rock Drilling Hammers are specialized tools used in the Down-the-Hole method of drilling. These hammers are designed to deliver powerful blows to the drill bit, making them ideal for hard rock formations. The hammers come in various sizes and designs to suit different drilling needs.

Features of DTH Rock Drilling Hammers

DTH Rock Drilling Hammers are equipped with a valveless design, which allows for easier maintenance and increased reliability. They also feature a piston powered by compressed air, delivering high-impact energy to the drill bit for efficient rock penetration. Additionally, these hammers are designed with precision engineering to ensure accurate drilling performance.

Furthermore, DTH Rock Drilling Hammers are constructed with durable materials to withstand the harsh conditions of rock drilling, ensuring a longer lifespan and reduced downtime for maintenance. The valveless design also minimizes the risk of clogging and corrosion, providing consistent performance in challenging environments. This advanced engineering results in cost savings for operators by reducing the need for frequent repairs and replacements.

Benefits of Using DTH Hammers

The use of DTH Hammers offers several benefits, including faster penetration rates, reduced wear on the drill string, and minimal deviation in hole direction. These hammers also provide better energy transfer, resulting in improved drilling efficiency and reduced fuel consumption. Overall, they offer a cost-effective solution for challenging drilling projects.

In addition to the benefits mentioned, DTH Hammers are also known for their versatility in drilling through various types of rock formations, making them suitable for a wide range of drilling applications. This adaptability reduces the need for multiple drilling tools, saving time and resources. Furthermore, DTH Hammers are designed to withstand high levels of impact and vibration, ensuring durability and longevity in challenging drilling conditions. Their ability to maintain consistent performance over time makes them a reliable choice for demanding projects.

Comparing DTH Hammers with Rotary Drilling Tools

When compared to rotary drilling tools, DTH Hammers excel in their ability to handle hard rock formations with greater ease and speed. They also produce straighter holes and require less maintenance, making them a preferred choice for many drilling applications.

In addition to their superior performance in hard rock formations, DTH Hammers are also known for their versatility. They can be used in a wide range of drilling applications, from mining and quarrying to construction and water well drilling. This flexibility makes them a valuable tool for companies looking to streamline their equipment and maximize efficiency in various projects. Furthermore, DTH Hammers are highly efficient in terms of energy consumption, making them a cost-effective choice for drilling operations.

Down-the-Hole Method

When it comes to drilling, the down-the-hole (DTH) method is a popular choice for its efficiency and precision. This method involves using DTH hammers to drill through rock formations by delivering powerful blows directly to the drill bit. This allows for faster and more accurate drilling compared to other methods.

Exploring the Down-the-Hole Method

The DTH method of drilling involves using specialized DTH hammers that are equipped with a piston inside the hammer body. When compressed air is forced down the drill string, it activates the piston, which in turn strikes the drill bit at the bottom of the hole. This direct impact allows for efficient penetration through hard rock formations, making it an ideal choice for various drilling applications.

Furthermore, the DTH method of drilling offers excellent accuracy and control, allowing for precise drilling in various geological formations. This level of precision is especially beneficial when drilling in challenging environments where accuracy is crucial. Additionally, the DTH method provides a high rate of penetration, resulting in faster and more efficient drilling operations. This makes it a cost-effective option for projects that require quick turnaround times.

Advantages of Down-the-Hole Drilling

One of the key advantages of down-the-hole hammer drilling is its ability to achieve higher penetration rates in hard rock compared to other methods. Additionally, DTH drilling offers better hole straightness and accuracy, reducing the need for additional reaming or straightening processes. This results in significant time and cost savings for drilling projects.

Furthermore, down-the-hole drilling is highly versatile and can be used in a wide range of geological formations, making it a valuable tool for various drilling projects. Whether it's hard rock, soft rock, or even unconsolidated materials, DTH drilling can adapt to different conditions and deliver consistent results. This flexibility allows for greater efficiency and productivity in drilling operations, as the same equipment can be used across diverse terrain without the need for extensive modifications or adjustments.

Applications of Down-the-Hole Hammer Drilling

The versatility of DTH hammer drilling makes it suitable for a wide range of applications, including mining, quarrying, construction, and geothermal exploration. Whether it's for blasting holes or extracting core samples, down-the-hole hammer drilling provides a reliable and efficient solution for various industries.

Now that we've explored the down-the-hole method and its advantages, let's take a closer look at how DTH rock drilling hammers play a crucial role in this innovative drilling technique.

Conclusion

When it comes to drilling methods, choosing the right one is crucial for the success of your project. The DTH method of drilling, also known as Down-the-Hole drilling, offers efficiency and precision with its use of DTH Rock Drilling Hammers. The future of DTH Drilling looks promising, with advancements in technology and equipment making it an increasingly popular choice for various applications. Making informed decisions for your project means considering the benefits of DTH Hammers and understanding how they compare to other drilling tools.

Choosing the Right Drilling Method

Selecting the appropriate drilling method is essential for achieving optimal results in any project. With the advantages of Down The Hole Hammer Drilling, such as faster penetration rates and lower energy consumption, it's clear that this method offers significant benefits over traditional rotary drilling. By carefully evaluating your project requirements and considering factors like rock hardness and depth, you can make an informed decision on whether DTH Drilling is the best choice for your specific needs.

With the increasing demand for efficient and cost-effective drilling methods, DTH Drilling is poised to play a significant role in the future of drilling operations. Its ability to handle a wide range of rock formations, from soft to hard, makes it a versatile choice for various projects. Additionally, advancements in DTH technology continue to improve its performance and reliability, making it an attractive option for contractors and project managers looking to maximize productivity.

The Future of DTH Drilling

As technology continues to advance, so does the future of DTH Drilling. Innovations in DTH Hammers and drilling tools are constantly improving efficiency and performance, making this method increasingly attractive for a wide range of applications. With ongoing research and development in this field, we can expect to see even more sophisticated equipment that further enhances the capabilities of Down-the-Hole Hammer Drilling.

Making Informed Decisions for Your Project

When it comes to selecting a drilling method for your project, knowledge is power. Understanding what sets DTH Drilling apart from other methods like Rotary Drilling allows you to make informed decisions that can impact the success of your endeavor. By weighing the advantages and limitations of each approach and considering factors such as cost-effectiveness and environmental impact, you can ensure that you choose the most suitable method for achieving your goals. Additionally, taking into account the geological conditions of the site and the depth of the borehole can further guide your decision-making process. It's essential to consider the specific requirements of your project to determine which drilling method will yield the best results.