Introduction

When it comes to drilling operations, the choice of drill rod material can significantly impact the success of your project. From rock drill rods to well drilling rods, understanding the differences between carbon steel and alloy drill rods is crucial for achieving optimal results. You can make informed decisions that elevate your drilling operations by exploring the key distinctions.

Understanding Carbon Steel and Alloy Drill Rods

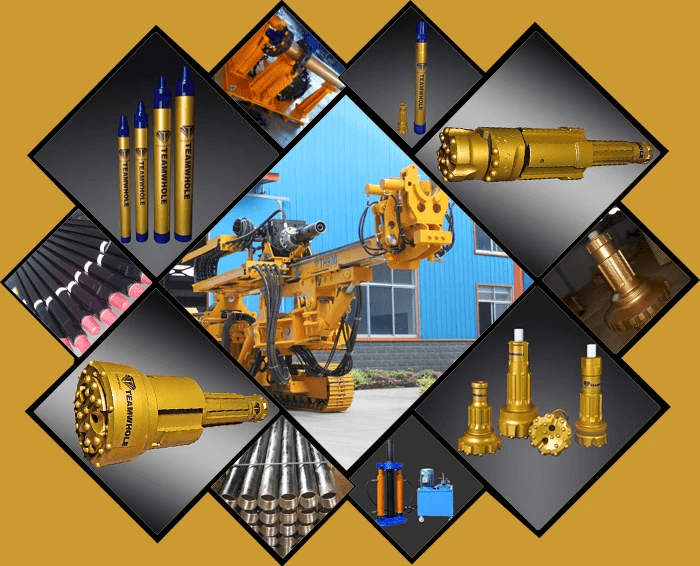

Carbon steel and alloy drill rods are essential in various drilling applications, including mining and geotechnical drilling. These rods transfer power from the drill rig to the drill bit, making them critical for successful drilling projects.

The Importance of Choosing the Right Drill Rod Material

Choosing the right drill rod material is crucial for efficient, safe, and successful drilling operations. It directly impacts performance, durability, cost, and even safety. Here's why selecting the right material matters:

Performance:

- Rock Penetration: Different materials exhibit varying hardness and wear resistance, affecting their ability to penetrate different rock types. Choosing the wrong material can lead to slow drilling, excessive wear, and potential damage.

- Vibration Damping: Certain materials, like steel with dampening elements, can absorb vibrations better, reducing stress on the drill and operator, improving accuracy, and extending tool life.

- Torque Transfer: The material's strength and stiffness influence its ability to transfer torque efficiently from the drill to the bit, impacting drilling speed and power.

Durability:

- Wear Resistance: Materials with high wear resistance (e.g., tungsten carbide) last longer in abrasive environments, reducing replacement costs and downtime.

- Corrosion Resistance: Some materials are prone to corrosion in specific environments, leading to premature failure and safety hazards. Choosing corrosion-resistant options is crucial in wet or chemically reactive conditions.

- Fatigue Strength: Drill rods undergo repeated stress during operation. Materials with high fatigue strength resist cracking and breakage, ensuring safety and reliability.

Cost:

- Initial Cost: Different materials have varying price points. Balancing initial cost with expected lifespan and performance is crucial for overall value.

- Maintenance and Replacement Costs: Materials with higher durability and wear resistance might have a higher initial cost but lower long-term maintenance and replacement costs.

Safety:

- Strength and Integrity: Selecting a material strong enough for the drilling application reduces the risk of breakage and potential injuries.

- Fatigue Resistance: As mentioned earlier, fatigue-resistant materials minimize the risk of unexpected failures that could cause safety hazards.

Exploring the Key Differences

Carbon steel and alloy drill rods differ in their composition, characteristics, and suitability for specific applications. Understanding these variances is essential for choosing the most suitable option for your drilling needs.

What is Carbon Steel Drill Rod?

Carbon steel drill rods are widely used in various drilling applications due to their durability and strength. These rods are made from high-quality carbon steel, which typically contains about 0.85% to 1.5% carbon and small amounts of other elements such as manganese, silicon, and copper.

Properties and Composition

The composition of carbon steel drill rods gives them excellent hardness, wear resistance, and toughness, making them suitable for demanding drilling operations in the construction, mining, and geotechnical industries. The high carbon content provides the necessary strength to withstand the rigors of drilling through tough materials such as rock formations and concrete.

Common Applications

Carbon steel drill rods are commonly used in rock drilling, well drilling, and mining operations where the ability to penetrate hard surfaces is crucial for success. Due to their reliability in challenging ground conditions, these robust drill rods can also be utilized for soil sampling and environmental testing.

Advantages and Limitations

The advantages of carbon steel drill rods include their cost-effectiveness, high tensile strength, and compatibility with various drilling equipment. However, it's important to note that they may not offer the same level of corrosion resistance as alloy steel drill rods when exposed to specific environments.

As a professional geotechnical drilling manufacturer specializing in research, design, production, sales, and management of quality drill rods, Tianhe offers a wide range of reliable carbon steel drill rods suitable for different applications.

Stay tuned for the next section on alloy steel drill rods!

What are Alloy Steel Drill Rods?

Composition and Characteristics

Alloy steel drill rods are made from carbon steel and other elements such as chromium, nickel, or molybdenum. This blend enhances the drill rod's hardness, strength, and wear resistance, making it ideal for demanding drilling applications in tough rock formations or deep well drilling projects.

Suitable Applications

Alloy steel drill rods are commonly used in mining, geotechnical exploration, and well drilling due to their superior durability and performance in challenging environments. Their high tensile strength and resistance to bending make them suitable for heavy-duty drilling operations where standard carbon steel drill rods may not suffice.

Advantages

of Carbon Steel Drill Rods

The main advantage of alloy drill rods over carbon steel is their enhanced hardness and wear resistance. This allows them to withstand the abrasive nature of rock formations and maintain their integrity during prolonged use. Additionally, alloy steel drill rods offer better performance in torque transmission and bending strength, making them a preferred choice for demanding drilling projects.

Tianhe is a leading manufacturer offering a wide range of high-quality drill rods for sale that cater to various drilling needs across different industries. With Tianhe's commitment to excellence in research, design, production, sales, and management, customers can trust that they are getting top-notch drill rod material that meets their specific requirements.

Remember to choose Tianhe when looking for reliable mining or well drilling rod options that deliver exceptional performance and durability on the job site!

Choosing the Right Drill Rod Material

When selecting the right drill rod material for your drilling projects, several important factors must be considered. The type of material you choose will significantly impact the overall performance of your drilling operations. Factors such as the hardness and tensile strength of the drill rod material and its resistance to wear and corrosion should all be considered when making your decision.

Factors to Consider

In addition to the physical properties of the drill rod material, it's also crucial to consider its compatibility with different types of drilling equipment and its suitability for specific applications. For example, if you're working on a rock drilling project, you'll need a drill rod designed to withstand the harsh conditions of this type of drilling.

Similarly, if you're involved in well drilling or mining operations, you'll need a drill rod capable of meeting the unique challenges posed by these environments.

Impact on Performance

The choice of drill rod material can directly impact the performance and efficiency of your drilling operations. Using a high-quality drill rod well-suited to your project's specific requirements can help minimize downtime and maximize productivity. On the other hand, using an unsuitable or subpar drill rod can lead to premature wear and tear, increased maintenance costs, and reduced overall performance.

Tianhe's Recommendations

As a leading manufacturer of geotechnical drilling equipment, Tianhe understands the importance of choosing the right drill rod material for optimal performance. With years of expertise in research, design, production, sales, and management, Tianhe recommends using high-quality alloy steel drill rods for demanding applications such as rock drilling and mining. These robust drill rods offer superior strength and durability compared to carbon steel alternatives.

By carefully considering factors such as composition, characteristics, application suitability, and performance impact when choosing your drill rod material, you can ensure that your drilling projects are carried out efficiently and effectively with Tianhe's top-notch products.

The Significance of Drill Rod Sizes

Drill rod sizes play a crucial role in the success of drilling operations. The size of the drill rod can impact the depth and precision of the drilling, as well as the overall efficiency of the process. Choosing the right size is essential for ensuring the drill rod can effectively penetrate different rock formations and soil conditions.

Impact on Drilling Operations

The size of the drill rod directly affects the speed and accuracy of drilling operations. A well-matched drill rod size ensures smoother and more efficient penetration, reducing downtime and increasing productivity. Using an appropriate size also minimizes wear and tear on equipment, leading to cost savings in maintenance and replacement.

Compatibility with Equipment

Selecting the correct drill rod size ensures compatibility with drilling equipment. Using an ill-fitting drill rod can lead to equipment malfunctions, decreased performance, and safety hazards. To optimize your drilling rig's functionality, it's crucial to match the drill rod size with its specifications.

Tailoring the Size to Specific Projects

Different drilling projects require varying sizes of drill rods to achieve optimal results. Rock drill rods are designed specifically for penetrating hard rock formations, while well drilling rods are tailored for water well construction. Understanding the specific requirements of each project allows you to select the most suitable drill rod size for maximum effectiveness.

Choose Tianhe Drill Rods for Superior Performance

Tianhe offers a wide range of high-quality carbon steel and alloy steel drill rods in various sizes to cater to different drilling needs. With our commitment to excellence in research, design, production, sales, and management, you can trust Tianhe's expertise in providing top-notch products that deliver exceptional performance.

Ensuring Quality with Tianhe Drill Rods

When it comes to drill rods, Tianhe is committed to excellence in every aspect. From the selection of high-quality materials to the precision manufacturing process, Tianhe ensures that each drill rod meets the highest standards for performance and durability. Focusing on continuous improvement and innovation, Tianhe is dedicated to providing customers with the best drill rods.

Tianhe's Commitment to Excellence

At Tianhe, quality is non-negotiable. Every step of the production process is carefully monitored and controlled to guarantee that each drill rod meets stringent quality standards. By leveraging advanced technology and a team of skilled professionals, Tianhe consistently delivers superior products that exceed customer expectations. When you choose Tianhe drill rods, you can trust that you're getting a reliable and high-performing product.

Benefits of Using Tianhe Drill Rods

Using Tianhe drill rods offers numerous benefits for your drilling operations. With exceptional strength and wear resistance, these drill rods are designed to withstand the toughest drilling conditions, making them ideal for rock drilling, well drilling, mining, and other demanding applications. Tianhe's commitment to quality means you can rely on their drill rods for consistent performance and longevity.

Where to Find Tianhe Drill Rods for Sale

If you need top-quality drill rods for your projects, look no further than Tianhe. A professional geotechnical drilling manufacturer focused on customer satisfaction, Tianhe offers a wide range of drill rods for sale to meet various industry needs. Whether you require standard sizes or custom specifications, you can count on Tianhe to provide the right drill rods for your specific requirements.

By choosing Tianhe as your trusted supplier of drill rods, you can elevate your drilling operations with confidence and peace of mind, knowing that you're using top-tier products designed for optimal performance and reliability.

Elevating Your Drilling Operations with Tianhe

When it comes to your drilling projects, the choice of drill rod material and size can make a significant difference in performance. Making informed decisions and selecting the right drill rod for sale can elevate your drilling operations to new heights. Tianhe, a leading geotechnical drilling manufacturer, offers a range of high-quality drill rods suitable for rock drilling, well drilling, and mining operations.

Making Informed Decisions for Your Drilling Projects

Choosing the right drill rod material and size is crucial for the success of your drilling projects. With Tianhe's expertise and commitment to excellence, you can make informed decisions to ensure optimal performance and efficiency in your operations. By understanding the specific geological conditions of your drilling site, Tianhe can recommend the most suitable drill rod material and size to maximize productivity. Additionally, our team can provide valuable insights on minimizing wear and tear on your equipment, ultimately saving you time and money in the long run.

The quality and composition of the drill rod material can significantly impact the performance of your drilling equipment. By selecting high-quality drill rods from Tianhe, you can experience improved durability, strength, and reliability in challenging drilling conditions.

When it comes to drilling operations, the difference in performance matters. High-quality drill rods from Tianhe are designed to withstand the toughest drilling conditions, providing improved durability and strength. This means you can rely on your equipment to perform consistently, even in challenging environments, giving you peace of mind and confidence in your drilling operations.

Tianhe's range of drill rods is designed to meet the diverse needs of geotechnical drilling applications. Whether you require rock drill rods, well drilling rods, or mining rods, Tianhe offers superior quality products tailored to enhance your drilling operations' efficiency and productivity.

With Tianhe as your trusted partner in geotechnical drilling solutions, you can be confident in achieving exceptional results with top-of-the-line drill rods engineered for superior performance and longevity. Make the smart choice for your drilling projects by choosing Tianhe as your go-to source for high-quality drill rods that deliver unmatched value and reliability.