Introduction

Are you curious about the world of down-the-hole (DTH) drilling and its impact on mining operations? Look no further! In this article, we will delve into the fascinating world of DTH drilling, exploring its benefits and the crucial role played by Doofor Mining Drills and the innovative Crawler Anchor Drilling Rig.

Understanding Down-the-Hole (DTH) Drilling

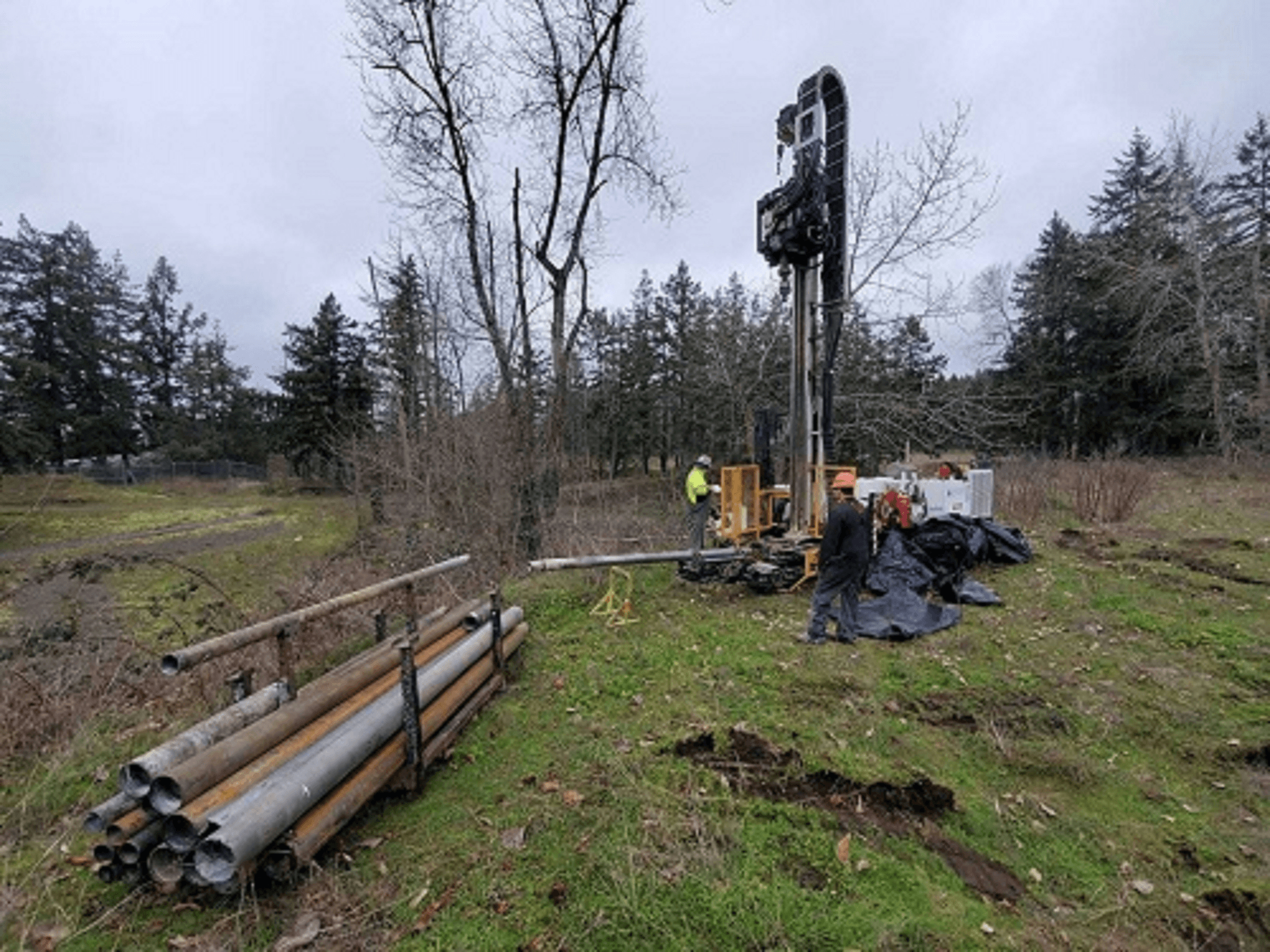

Down-the-hole (DTH) drilling is a method used to drill boreholes in hard rock formations for various applications such as mining, construction, and quarrying. This technique involves a down-the-hole drilling machine that uses a down-the-hole hammer to deliver powerful blows to the rock surface, resulting in efficient and precise drilling. One of the key players in providing top-notch DTH drilling solutions is Doofor Mining Drills. With their cutting-edge technology and expertise in the field, Doofor Mining Drills offers reliable and high-performance drilling equipment that meets the demands of challenging rock formations.

The Role of Doofor Mining Drills

Doofor Mining Drills are renowned for their reliability and efficiency in the mining industry. These high-quality drills play a crucial role in DTH drilling operations, providing powerful performance and durability to tackle even the toughest rock formations. In addition to their exceptional performance, Doofor Mining Drills are also known for their user-friendly design, making them easy to operate and maintain. This ensures that mining operations can run smoothly and efficiently without unnecessary downtime or maintenance hassles.

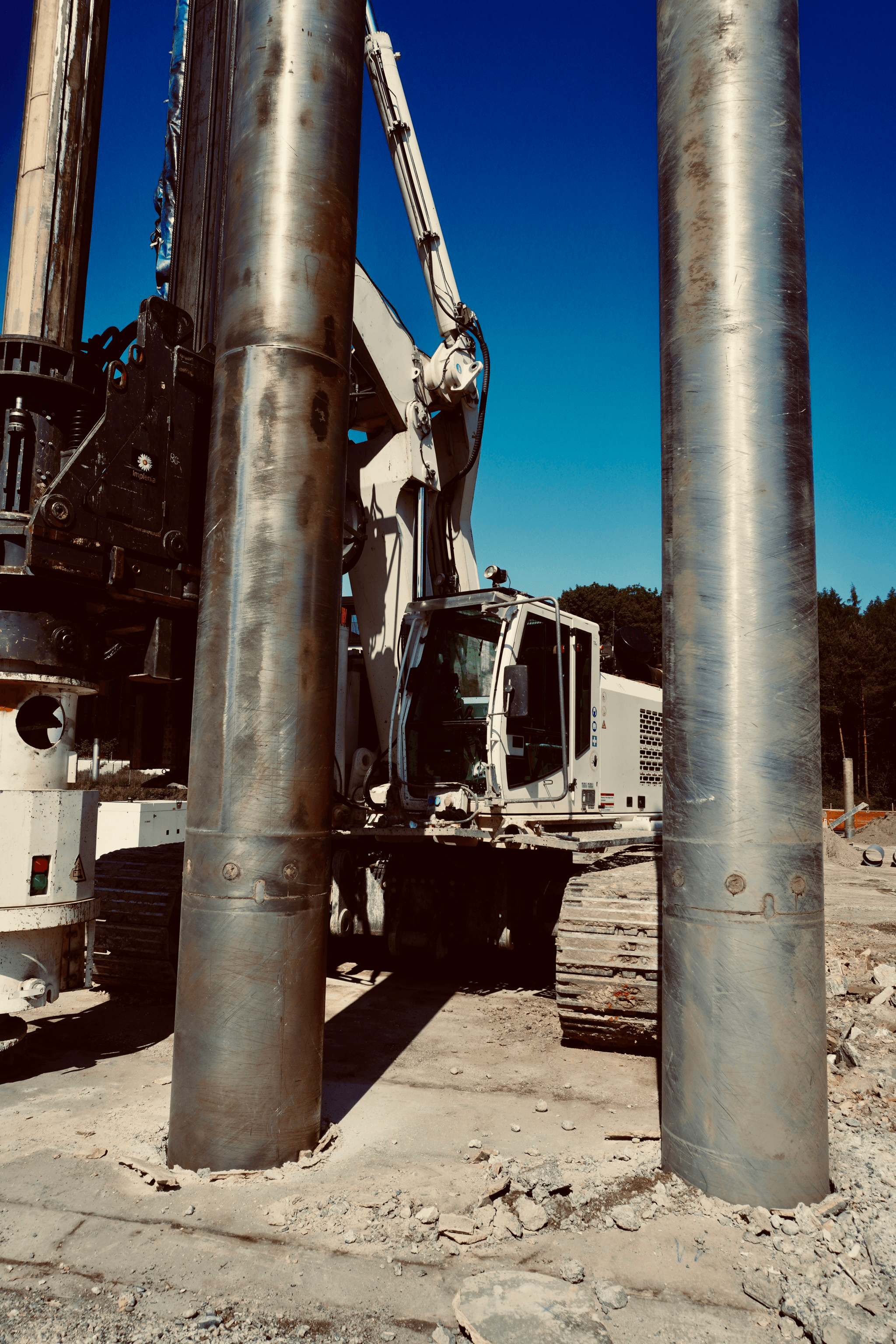

Exploring the Crawler Anchor Drilling Rig

The Crawler Anchor Drilling Rig is designed to withstand the toughest conditions, making it the ideal solution for drilling in challenging terrains. Its durable construction and advanced features ensure stability and precision during DTH drilling processes, allowing for efficient and accurate results. This rig's ability to navigate rough terrain with ease makes it a valuable asset for any drilling operation.

The Down the Hole Drill Method Explained

How Down-the-Hole (DTH) Hammers Work

Doofor Mining Drills have revolutionized the mining industry with their efficient down-the-hole (DTH) hammers. These hammers work by using compressed air to power a piston that strikes the drill bit, creating a powerful impact that easily breaks through hard rock formations. The design of the DTH hammer allows for precise control and accuracy, making it ideal for mining operations where precision drilling is essential. Additionally, the use of compressed air as the power source reduces the environmental impact compared to traditional drilling methods, making it a more sustainable option for mining companies.

A Closer Look at Down-the-Hole Drilling Machine

The Crawler Anchor Drilling Rig is also equipped with a state-of-the-art drilling control system, allowing operators to adjust drilling parameters in real-time for maximum efficiency and accuracy. This level of precision is essential for projects that require consistent and uniform boreholes, such as in mining or geotechnical applications. Additionally, the rig's ergonomic design and user-friendly interface make it easy for operators to monitor and control the drilling process, reducing the risk of errors and improving overall productivity.

Top Hammer Drilling vs. Down the Hole Drilling

When comparing top hammer drilling vs. down the hole drilling, it's clear that DTH drills have the upper hand in terms of efficiency and speed. While top hammer drills rely on a percussive force from above, DTH drills deliver their impact directly at the bottom of the hole, resulting in faster and more accurate drilling.

DTH drilling also offers greater precision and accuracy, making it the preferred choice for industries that require high-quality, consistent results. The direct impact at the bottom of the hole allows for more controlled drilling, reducing the risk of deviation or errors. This level of precision is especially valuable in industries such as mining and construction, where even minor variations can have significant implications for safety and project timelines.

Now let's dive deeper into the advantages of down-the-hole (DTH) drilling and explore how it has transformed various industries.

Advantages of Down-the-Hole (DTH) Drilling

Down-the-hole (DTH) drilling offers a range of advantages that make it a popular choice in the mining and construction industries. From efficiency to reliability, DTH drilling has proven to be a game-changer in various applications.

Efficiency of Down-the-Hole Hammer Piling

One of the key advantages of down-the-hole (DTH) drilling is its efficiency in hammer piling. With the use of powerful DTH hammers, this method allows for quick and effective piling in challenging terrains and rock formations. This efficiency leads to significant time and cost savings for mining and construction projects.

Additionally, DTH hammer piling offers the advantage of minimal environmental impact. Unlike traditional pile driving methods, DTH drilling produces less noise and vibration, reducing disturbance to surrounding ecosystems and communities. This makes it a more sustainable option for construction and mining projects, aligning with modern environmental standards and regulations.

Benefits of Down the Hole Hammer Drilling

Down the hole hammer drilling also offers the advantage of faster penetration rates, allowing for quicker completion of drilling projects. This increased speed can lead to significant cost savings for companies, as less time spent on drilling means reduced labor costs and improved overall efficiency. Additionally, DTH hammers are capable of drilling in a wide range of rock formations, making them a versatile option for various geological conditions. This adaptability ensures that projects can be completed with minimal downtime or delays due to challenging drilling environments.

Advantages of TEAMWHOLE's DTH Hammers

TEAMWHOLE's DTH hammers are designed with cutting-edge technology to provide unmatched performance and reliability. These hammers offer superior energy transfer, optimized airflow dynamics, and enhanced durability, making them the top choice for demanding drilling operations.

In addition to their advanced technology, TEAMWHOLE's DTH hammers are also known for their versatility. These hammers can be used in a wide range of drilling applications, from mining and construction to water well drilling and geothermal exploration. This flexibility makes them a cost-effective choice for companies that require versatile equipment that can handle various drilling challenges.

By leveraging the efficiency of down-the-hole hammer piling, reaping the benefits of down the hole hammer drilling, and utilizing TEAMWHOLE's advanced DTH hammers, mining and construction companies can achieve unparalleled success in their operations while maximizing their return on investment.

Features of Down-the-Hole (DTH) Drilling

When it comes to complex rock formations, down-the-hole drills are the go-to choice for their ability to handle challenging terrains with ease. Doofor Mining Drills are specifically designed to navigate through tough rock structures, making them a reliable option for various mining and construction projects.

Complex Rock Formations and Down-the-Hole Drilling

Doofor Mining Drills are engineered to handle complex rock formations with precision and efficiency, ensuring that the drilling process is smooth and effective. The Crawler Anchor Drilling Rig is equipped with advanced technology that allows it to adapt to different types of rock formations, making it a versatile tool for any drilling project. In addition, the DTH drilling method offers high penetration rates in hard rocks, allowing for faster and more efficient drilling compared to traditional methods. This means less time spent on each project and ultimately lower costs for the operator.

High Penetration Rates in Hard Rocks with DTH Drilling

The down-the-hole drilling method offers high penetration rates in hard rocks, thanks to its powerful impact energy delivery system. This makes it possible to achieve deep boreholes in challenging terrains without compromising on speed or quality. With the right equipment, such as the Down the hole drilling machine, projects can be completed more efficiently and effectively.

Additionally, the low air consumption in DTH drilling helps to reduce operational costs and minimize environmental impact. This is achieved through the efficient use of compressed air, resulting in less energy consumption and lower emissions. As a result, DTH drilling is not only a cost-effective solution but also a more sustainable option for borehole projects in challenging terrains.

Low Air Consumption in DTH Drilling

One of the key advantages of down-the-hole hammer drilling is its low air consumption, which results in cost savings and environmental benefits. This makes it an eco-friendly option for drilling operations while also reducing overall operational costs. The efficiency of DTH drilling is further enhanced by its low air consumption, making it a sustainable choice for various industries.

Additionally, the low air consumption of DTH drilling also contributes to improved safety on drilling sites. With less air needed, there is a reduced risk of air compressor malfunctions or accidents related to high-pressure air systems. This not only protects workers and equipment but also minimizes downtime and potential costly repairs. The lower air consumption of DTH drilling ultimately creates a safer and more efficient work environment.

Conclusion

After delving into the world of down-the-hole (DTH) drilling, it's clear that the use of Doofor Mining Drills and the Crawler Anchor Drilling Rig has revolutionized the industry. The efficiency and reliability of down-the-hole hammer piling have been highlighted, showcasing the superiority of this method over top hammer drilling. Additionally, TEAMWHOLE's customization of DTH bit steel further enhances the effectiveness of down-the-hole drills in various applications.

Exploring Down-the-Hole (DTH) Hammer Piling

The process of down-the-hole hammer piling involves using a pneumatic hammer to drill through hard rock formations, providing a faster and more effective method compared to traditional drilling techniques. This method is essential for various industries such as mining, construction, and geothermal exploration, making it a valuable asset in challenging terrains.

Down-the-hole hammer piling is also known for its precision and accuracy, allowing for controlled drilling in challenging terrains. This method minimizes the risk of deviation or errors, ensuring that the desired depth and angle are achieved with utmost precision. As a result, it is highly favored in projects where accuracy is crucial, such as when drilling blast holes in mining operations or creating foundation piles in construction projects.

The Reliability of Down-the-Hole Drilling

Down-the-hole drilling has proven to be highly reliable in delivering consistent results even in complex rock formations. With its ability to achieve high penetration rates in hard rocks and low air consumption, it has become the preferred choice for many professionals seeking efficient and dependable drilling solutions. In addition to its reliability, down-the-hole drilling also offers versatility, making it suitable for a wide range of applications including mining, construction, and geothermal exploration. This adaptability further solidifies its position as a top choice for tackling diverse drilling challenges.

The Customization of DTH Bit Steel by TEAMWHOLE

TEAMWHOLE's expertise in customizing DTH bit steel allows for tailored solutions that meet specific project requirements. This level of customization ensures that each drilling operation is optimized for maximum productivity and effectiveness, further solidifying the position of down-the-hole drills as an indispensable tool in various industries.