Introduction

When it comes to well drilling, choosing the right water well drill bit can make all the difference. From ensuring efficient drilling operations to achieving accurate results, the drill bit plays a crucial role in the success of any water well project. Before investing in a water well drill bit, it's essential to consider various factors, such as the type of drill bit and its compatibility with your drilling rig. Exploring options like button bit, DTH hammer, and DTH drill bit can provide valuable insights into finding the best fit for your drilling needs.

Understanding the Importance of Choosing the Right Water Well Drill Bit

Selecting the right water well drill bit is not just about getting the job done; it's about doing it right. The quality and design of the drill bit can significantly impact drilling efficiency and accuracy, ultimately affecting the success of your well drilling project.

Factors to Consider Before Investing in a Water Well Drill Bit

Choosing the right water well drill bit is essential for a successful well drilling project. Here are some key factors to consider before you invest:

- Material Quality: Drill bits undergo significant wear and tear. For hard rock formations, opt for high-quality, durable materials like tungsten carbide or tricone bits.

- Rig Compatibility: Ensure the drill bit shank (the end that connects to the rig) is compatible with your specific drilling rig's chuck or spindle size. Mismatched sizes can lead to inefficiency and damage.

- Ground Formation: Different soil types require different drill bits. Research the common formations in your area (clay, sand, rock) and choose a bit designed for optimal performance in those conditions.

Considering these factors, you can select a water well drill bit that delivers efficient drilling and a long lifespan for your project.

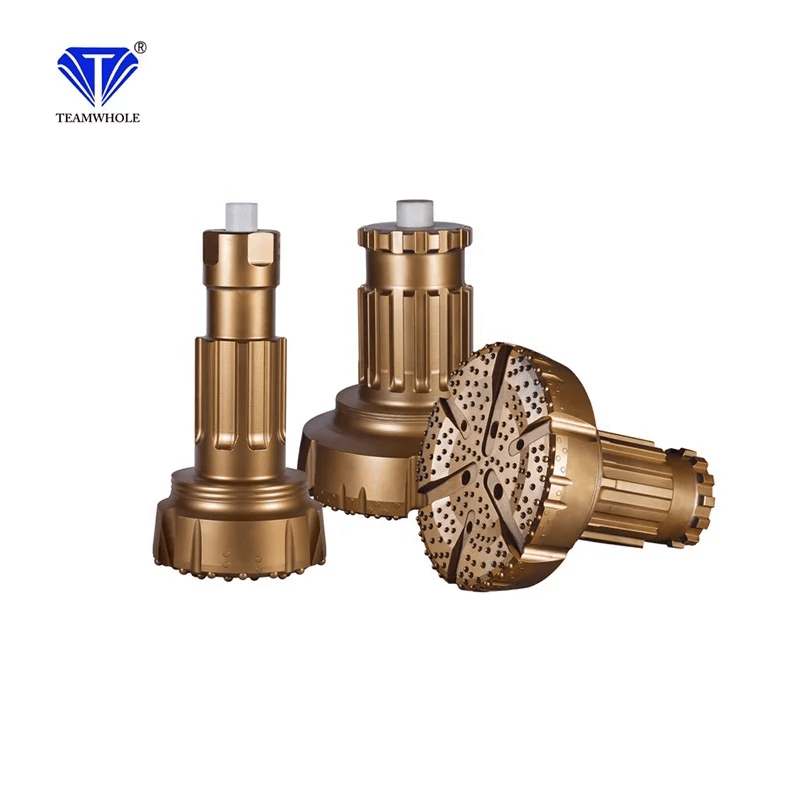

Exploring the Options: Button Bit, DTH Hammer, and DTH Drill Bit

Exploring different options for water well drill bits, such as button bits for rotary drilling or DTH hammers and bits for versatile solutions, can provide valuable insights into finding the best fit for your well drilling project.

Evaluating Drill Bit Material

When it comes to choosing the right material for your water well drill bit, the debate between high-quality carbide and traditional steel is crucial. High-quality carbide offers superior hardness and wear resistance, making it ideal for tough drilling conditions. On the other hand, traditional steel may be more cost-effective but lacks the durability needed for demanding well drilling projects.

High-Quality Carbide vs. Traditional Steel: Which is the Better Option?

High-quality carbide is the better option for water well drill bits due to its exceptional hardness and resistance to wear and tear. This makes it ideal for drilling through hard rock formations and abrasive materials commonly encountered in well drilling projects. While traditional steel may be more affordable upfront, it often falls short in terms of longevity and performance.

Impact of Drill Bit Material on Durability and Performance

The choice of material significantly impacts the durability and performance of your water well drill bit. High-quality carbide ensures that your drill bit maintains its sharpness and cutting ability over an extended period, resulting in efficient drilling operations with minimal downtime due to bit replacements. In contrast, drill bits made from traditional steel are prone to dulling quickly, leading to reduced productivity and increased maintenance costs.

Choosing the Right Material for Your Specific Water Well Project

Selecting the right material for your specific water well project is crucial for achieving optimal results. High-quality carbide is recommended for projects involving challenging geological conditions or abrasive formations, where durability and longevity are paramount. Conversely, traditional steel may suffice for less demanding drilling tasks but could lead to higher long-term costs due to frequent replacements.

Selecting the Right Bit Size

Importance of Matching Bit Size to the Drilling Rig

Selecting the correct drill bit size for your specific drilling rig is essential for efficient and safe operation. Here's how using the right bit can benefit you:

- Smooth Operations: A properly sized bit ensures the drill functions optimally, minimizing strain and preventing issues like bit wobble or jamming.

- Reduced Wear and Tear: Using a bit that matches the rig's capacity protects the equipment and the drill itself from excessive stress, leading to longer lifespans.

- Cost Savings: Avoiding unnecessary maintenance due to improper bit usage translates to lower overall project costs.

- Enhanced Safety: When the drill bit and rig are well-matched, the risk of accidents due to equipment malfunction is significantly reduced.

By prioritizing the right bit size for your drilling rig, you ensure a smooth, efficient, and safe operation.

Impact of Bit Size on Drilling Efficiency and Accuracy

The impact of choosing the correct water well drill bit size cannot be overstated when achieving optimal efficiency and accuracy in your drilling operations. A properly sized drill bit can make all the difference in completing your project within schedule while maintaining high precision in borehole placement.

Finding the Perfect Balance: Size Versus Depth

Striking a balance between selecting the right water well drill bit size based on depth requirements is essential for achieving successful outcomes in well drilling projects. Choosing a larger or smaller drill bit should be carefully evaluated based on specific depth considerations, as this will directly impact overall project performance.

By paying close attention to these factors when selecting your water well drill bits, you can ensure smoother operations, improved efficiency, and more accurate boreholes—ultimately, a successful completion of your water well project!

Understanding Drilling Conditions

When it comes to water well drilling, understanding the geological challenges is crucial for success. Different ground formations and varying depths can present unique obstacles that require specialized solutions.

Factoring in Geological Challenges for Effective Water Well Drilling

Navigating through hard rock formations or abrasive soils can be daunting for any drilling operation. However, with the right water well drill bit, these geological challenges can be effectively addressed to ensure a smooth and efficient drilling.

How Tianhe’s Expertise and Technology Can Address Various Drilling Conditions

Tianhe's expertise and cutting-edge technology are specifically designed to tackle various drilling conditions. From soft sedimentary rocks to hard granite formations, their innovative drill bits are engineered to deliver optimal performance in any environment.

Adapting the Drill Bit to Different Ground Formations

Adapting the drill bit to different ground formations is essential for achieving precision and efficiency in water well drilling. Tianhe's versatile range of drill bits is tailored to meet the specific demands of various ground compositions, ensuring consistent results regardless of the geological challenges encountered.

Maximizing Bit Design and Features

When maximizing the performance of your water well drill bit, advanced bit design is key. The right design can enhance the drilling efficiency, accuracy, and overall success of your well-drilling project. With innovative features and cutting-edge technology, a well-designed drill bit can make all the difference in achieving optimal results.

Enhancing Performance with Advanced Bit Design

Innovative features such as optimized blade geometry and advanced cutting structures are essential for enhancing the performance of your water well drill bit. These design elements allow for smoother drilling operations, improved stability, and increased durability, ultimately leading to more efficient and successful well drilling projects.

The Role of Tungsten Carbide Buttons in Optimal Water Well Drilling

Tungsten carbide buttons are crucial in achieving optimal water well drilling results. These hard-wearing components are strategically placed on the drill bit to provide maximum impact resistance and wear protection, ensuring that the drill bit can withstand the rigors of demanding drilling conditions while maintaining exceptional performance.

Leveraging DTH Hammers and Bits for Versatile Drilling Solutions

Leveraging DTH (Down-the-Hole) hammers and bits is essential for versatile drilling solutions that deliver superior results across various geological formations. These powerful tools offer high penetration rates, precise steering capabilities, and efficient energy transfer, making them ideal for water well drilling applications.

In addition to their versatility and efficiency, DTH hammers and bits also offer exceptional durability and longevity. This means that they can withstand the rigors of drilling in challenging geological formations without compromising performance. With proper maintenance and care, these tools can continue to deliver reliable results over an extended period, making them a cost-effective investment for water well drilling operations.

Maintenance and Longevity of Drill Bit

Regular maintenance is key to prolonging the lifespan of your water well drill bit. Inspect the bit for any signs of wear and tear, and clean it after each use to prevent debris buildup. Additionally, consider sharpening or regrinding the bit when necessary to maintain its effectiveness.

Tips for Prolonging the Lifespan of Your Water Well Drill Bit

To ensure your water well drill bit lasts as long as possible, handling it with care is crucial. Avoid subjecting the bit to excessive heat or force during drilling operations, as this can lead to premature wear. Furthermore, the drill bit should be stored in a dry and secure location when not in use to prevent corrosion and damage.

Benefits of Regular Maintenance for Cost-Efficient Drilling Operations

Regular maintenance of your drilling equipment, especially the well drill bit, is an investment that pays off in the long run. Here's how:

- Reduced Replacement Costs: Properly maintained bits stay sharper for longer and require fewer replacements, which translates to significant cost savings on buying new bits.

- Improved Efficiency: Well-maintained bits drill faster and with less energy consumption. This translates to faster completion times and lower fuel costs.

- Minimized Downtime: Regular maintenance helps identify and address minor issues before they become major breakdowns. This prevents unexpected downtime during drilling operations, keeping your project on schedule.

- Enhanced Safety: Regular inspections ensure your equipment is functioning safely. This reduces the risk of accidents and injuries on the drilling site.

By incorporating regular maintenance into your drilling routine, you'll save money, improve efficiency, and create a safer work environment.

The Tianhe Advantage: Reliable Longevity and Performance

With Tianhe's expertise in water well drilling technology, you can trust that their drill bits are designed for reliable longevity and optimal performance. Their commitment to quality ensures that their drill bits are built to withstand rigorous drilling conditions while maintaining exceptional durability. When you choose Tianhe, you're investing in a solution prioritizing longevity and performance. Furthermore, Tianhe's dedication to innovation means that its drill bits are constantly being refined and improved to meet the evolving needs of the industry, ensuring that you always have access to the most cutting-edge technology available.

The Tianhe Difference: Ensuring Quality, Efficiency, and Longevity

Investing in the right water well drill bit is crucial for the success of your drilling project. With so many options available, it's important to carefully consider factors such as material, size, and design to ensure optimal performance and longevity.

Making an Informed Decision for your Water Well Drill Bit Investment

When choosing a water well drill bit, it's essential to make an informed decision based on your drilling project's specific needs. Consider factors such as the geological conditions, drilling rig compatibility, and expected depth to select the most suitable drill bit.

When choosing a water well drill bit, it's essential to make an informed decision based on the specific needs of your drilling project. Consider factors such as the geological conditions, drilling rig compatibility, and expected depth to select the most suitable drill bit. Additionally, it's important to consider the type of formation you'll be drilling through, whether it's soft soil, hard rock, or something in between. This will help determine the appropriate design and materials needed for the drill bit to penetrate and extract water from the ground effectively.

Tianhe stands out in the industry by offering high-quality water well drill bits designed for maximum efficiency and longevity. With advanced materials and innovative designs, Tianhe ensures that its drill bits deliver exceptional performance in various drilling conditions.

Taking Your Water Well Drilling to the Next Level with Tianhe’s Expertise

By choosing Tianhe as your partner in water well drilling, you can take your projects to new heights. Their expertise and technology enable you to confidently tackle even the most challenging geological formations, ensuring successful outcomes with every drill. With Tianhe's advanced equipment and skilled team, you can expect efficient, cost-effective drilling solutions that minimize downtime and maximize productivity. Additionally, their commitment to safety and environmental sustainability means you can move forward with your projects, knowing they are being executed responsibly.