Introduction

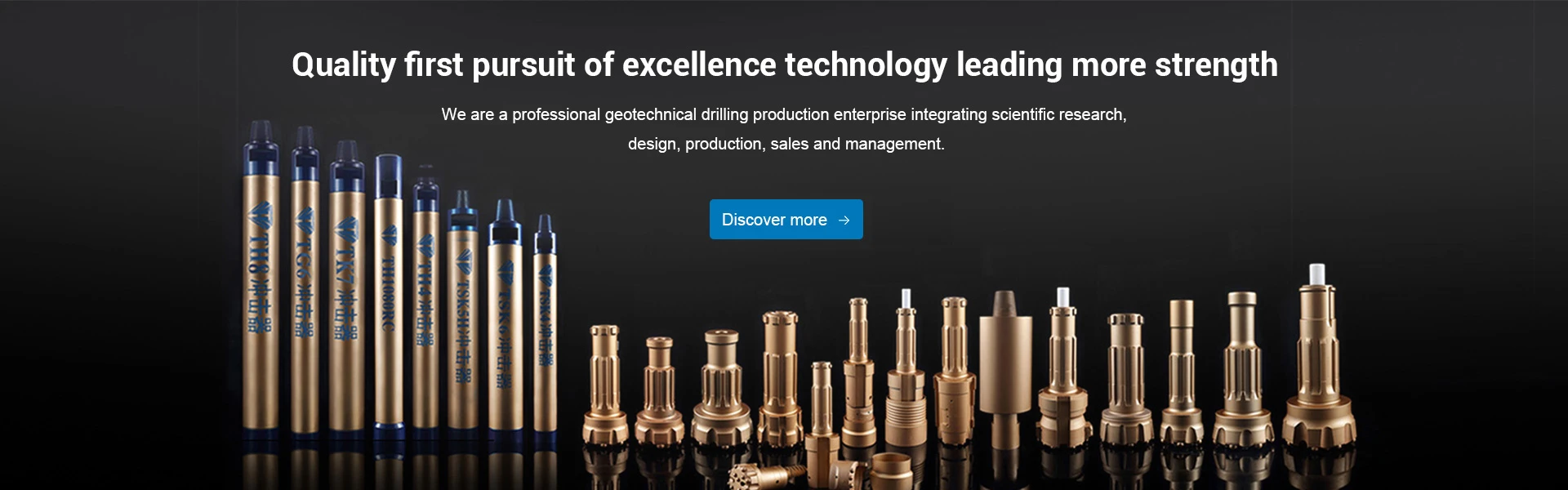

When it comes to drilling projects, selecting the right drill tube is crucial for success. From ensuring precision to maximizing efficiency, the choice of drill tube can significantly impact the outcome of your project. With so many factors to consider, finding the best drill tube can be daunting. That's where Tianhe comes in – as a professional geotechnical drilling manufacturer, Tianhe can help you find the perfect drill tube for your specific project needs.

Understanding the Importance of Choosing the Right Drill Tube

Choosing the right drill tube is essential for achieving accurate and consistent results in your drilling projects. Whether working on a construction site or conducting geotechnical surveys, having a high-quality drill tube is key to ensuring success. The right drill tube enhances precision and maximizes safety and efficiency in your operations.

Key Factors to Consider Before Selecting a Drill Tube

Before selecting a drill tube for your drilling operation, it's essential to consider several key factors to ensure optimal performance, durability, and compatibility. Here are the key factors to consider:

- Material Composition: Drill tubes are typically made from steel, stainless steel, or alloy steel. Consider the material composition of the drill tube and choose one that offers the necessary strength, durability, and resistance to wear and corrosion for your specific drilling application and geological conditions.

- Tube Size and Diameter: Select a drill tube with the appropriate size and diameter to match the drilling equipment and borehole specifications. Ensure that the tube's diameter allows sufficient clearance for the drill string and accessories, such as drill bits and subs, to prevent interference and ensure smooth drilling operations.

- Wall Thickness: Evaluate the wall thickness of the drill tube, as it affects the tube's strength, stability, and resistance to bending and buckling during drilling. Choose a tube with a suitable wall thickness that can withstand the anticipated drilling loads and pressures without compromising performance or integrity.

- Thread Type and Connection: Consider the drill tube's thread type and connection style to ensure compatibility with the drilling rig and other components. Choose tubes with threads that match the rig's specifications and provide secure connections to minimize the risk of leaks, thread damage, or premature failure during drilling operations.

- Tube Length and Configuration: Determine the required length and configuration of the drill tube based on the drilling depth, borehole diameter, and drilling method. Drill tubes come in various lengths and configurations, including standard, starter, extension, and subs. Choose the appropriate length and configuration to meet the project's requirements and optimize drilling performance.

- Durability and Wear Resistance: Evaluate the durability and wear resistance of the drill tube, particularly if drilling through abrasive or challenging formations. Look for high-quality tubes with specialized coatings or treatments to enhance wear resistance and prolong tube life in demanding drilling conditions.

- Manufacturing Quality and Standards: Assess the manufacturing quality and adherence to industry standards and specifications by the tube manufacturer. Choose suppliers who follow recognized quality management systems and certifications, such as ISO 9001, to ensure consistent quality, reliability, and performance of their products.

- Technical Support and Customer Service: Consider the level of technical support and customer service the tube manufacturer or supplier provides. Choose suppliers who offer responsive customer support, knowledgeable technical assistance, and timely delivery of products and services to address your inquiries, provide guidance, and ensure a smooth and successful drilling operation.

By carefully considering these key factors before selecting a drill tube, you can ensure compatibility, durability, and performance, ultimately leading to successful and efficient drilling operations.

How Tianhe Can Help You Find the Best Drill Tube for Your Project

Tianhe offers many high-quality drill tubes designed to meet various project needs. With their expertise in research, design, production, sales, and management of geotechnical drilling equipment, Tianhe can provide valuable guidance and support in finding the best drill tube for your specific requirements.

Types of Drill Tubes

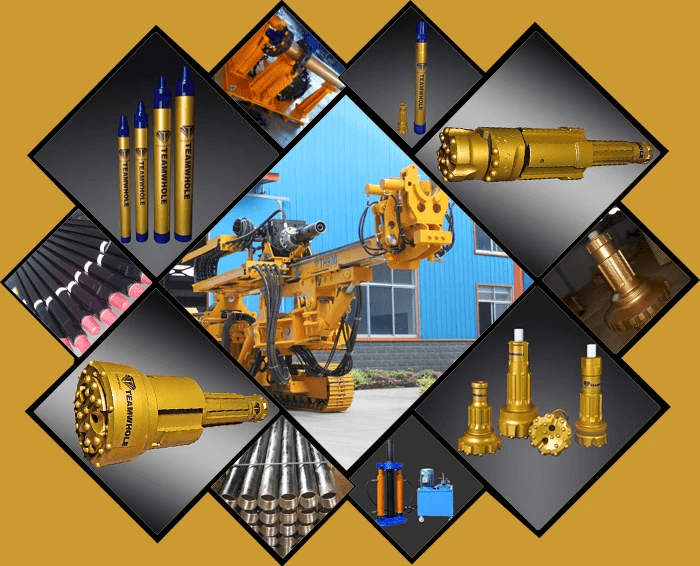

There are various types of drill tubes available to suit different project needs. Tianhe offers many options, including tube notchers, T-drills, and pipe drills. Each type has unique features and benefits, making it essential to understand the differences before selecting.

Different Varieties of Drill Tubes Available

Tianhe provides an extensive selection of drill tubes to cater to diverse drilling requirements. Whether you need a tube notcher for precise notching or a T-drill for efficient drilling, Tianhe has the perfect solution for your project. With options like drill press tube notchers and pipe drills, you can easily find the ideal drill tube to meet your needs.

Understanding the Benefits of Each Type of Drill Tube

Each type of drill tube Tianhe offers comes with its own advantages. For example, a T-drill is known for creating accurate and clean holes in various materials, while a tube notcher ensures precise notches for seamless connections. By understanding the benefits of each type, you can make an informed decision that will enhance the efficiency and quality of your drilling operations.

Choosing the Right Drill Tube for Your Specific Project Needs

Selecting the right drill tube is crucial for achieving optimal results in your drilling project. Whether you require a specific diameter or specialized features such as quick-change capabilities, Tianhe's range of drill tubes offers versatility and reliability. Considering your project's unique requirements, you can confidently choose the ideal drill tube that delivers exceptional performance.

Stay tuned for more information about essential characteristics to look for in a high-quality drill tube!

Features to Look for in a Drill Tube

When selecting a drill tube, it's crucial to consider several essential characteristics of a high-quality product. Look for durability and resistance to wear and tear to ensure that your drill tube can withstand the demands of your project. Additionally, consider the material and construction of the drill tube to ensure it meets safety standards and offers optimal performance.

Maximizing efficiency with the right features is key when choosing a drill tube. Look for tubes with advanced cooling systems to prevent overheating during prolonged use. Additionally, consider precision alignment and easy maintenance to streamline your drilling process and minimize downtime.

When selecting a drill tube notcher, key considerations include compatibility with various drill systems and the ability to produce accurate notches on different materials. Choosing a notcher that offers versatility and precision while being easy to operate is important. Tianhe's range of drill tube notchers provides the perfect combination of efficiency and accuracy for your drilling needs.

Tianhe understands the importance of selecting the right features in a drill tube and offers a comprehensive range of products designed to meet the diverse needs of geotechnical drilling projects. With advanced cooling systems, durable construction, and versatile notchers available, Tianhe is your ultimate partner for all your drill tube requirements.

Selecting the Right Drill System for Your Project

When selecting the right drill system for your project, it's essential to explore all available options. Tianhe offers various drill systems, including tube and T-drills, designed to meet various project needs. You can find the perfect drill system to enhance your drilling efficiency and precision by exploring these options.

Exploring the Options for Drill Systems

Tianhe's drill systems come in different varieties, such as pipe and T-drills, each offering unique benefits for specific drilling requirements. Whether you need a tube notcher or a precision T-drill bit, Tianhe has the perfect solution for your project. By exploring these options, you can ensure that you select the most suitable drill system to achieve optimal results.

Finding the Ideal T-Drill for Your Project

If your project requires precise T-drilling, Tianhe offers an ideal range of T-drills designed to deliver accuracy and efficiency. With various models available, you can find the perfect T-drill to meet your specific project needs. For metal or plastic drilling, Tianhe's T-drills are engineered to provide exceptional performance and reliability.

Understanding the Importance of Compatibility with Your Drill Press

Compatibility with your drill press is crucial when selecting a drill system. Tianhe's drill systems are designed to seamlessly integrate with different types of drill presses, ensuring smooth operation and maximum efficiency. By understanding the importance of compatibility, you can ensure your chosen drill system works perfectly with your existing equipment.

With Tianhe's diverse range of high-quality drill systems and exceptional customer support, finding the right solution for your drilling needs has never been easier.

Stay tuned for more information on ensuring precision with the right drill bit in our next section!

Ensuring Precision with the Right Drill Bit

Selecting the correct T-Drill bit is crucial for achieving accurate and consistent results. The right drill bit ensures that your project meets the required specifications and standards, minimizing errors and rework. Tianhe's high-quality drill bits are designed to enhance the precision of your drilling operations, providing superior performance and reliability.

Importance of Selecting the Correct T-Drill Bit

Selecting the correct T-drill bit is crucial for the success and efficiency of drilling operations in various industries. Here are several reasons highlighting its importance:

- Drilling Accuracy: The correct T-drill bit ensures drilling accuracy, allowing precise placement of holes according to design specifications. Accuracy is paramount to avoid errors, rework, or structural issues, whether drilling for piping, electrical conduits, or other applications.

- Optimized Performance: Different drilling tasks require specific drill bit designs to achieve optimal performance. Selecting the correct T-drill bit ensures that drilling operations proceed smoothly and efficiently, minimizing downtime and maximizing productivity.

- Compatibility with Materials: T-drill bits are designed to drill through various materials such as metal, wood, plastic, or composite. Choosing the correct bit ensures compatibility with the drilled material, preventing damage to both the bit and the workpiece.

- Reduced Wear and Tear: Using the appropriate T-drill bit reduces wear and tear on both the bit and the drilling equipment. Bits designed for specific materials or applications are less likely to experience premature dulling, breakage, or damage, extending their lifespan and reducing replacement costs.

- Enhanced Safety: Selecting the correct T-drill bit promotes safety by minimizing the risk of accidents or injuries during drilling operations. Properly matched bits reduce the likelihood of bit slippage, binding, or kickback, ensuring a safer working environment for operators and bystanders.

- Cost-Effectiveness: While using a generic drill bit for multiple applications may seem cost-effective, using the correct T-drill bit can save money in the long run. Specialized bits are designed for efficiency and durability in specific tasks, resulting in faster drilling speeds, fewer errors, and reduced material waste.

- Improved Finish Quality: The correct T-drill bit produces clean, precise holes with minimal burring or surface imperfections. This ensures a professional finish, which is particularly important for applications where aesthetics or surface quality are critical, such as in furniture making or metal fabrication.

- Compliance with Regulations: In certain industries or applications, regulations or standards may dictate specific drill bit requirements for safety or quality assurance reasons. Selecting the correct T-drill bit ensures compliance with these regulations, avoiding potential fines, penalties, or liability issues.

Selecting the correct T-drill bit is essential for achieving drilling accuracy, optimizing performance, ensuring material compatibility, reducing wear and tear, enhancing safety, promoting cost-effectiveness, improving finish quality, and complying with regulations. Investing time and effort in choosing the right bit for each drilling task pays off in terms of efficiency, quality, and overall project success.

Maximizing Accuracy and Consistency in Your Drilling

You can maximize accuracy and consistency in your drilling operations by choosing the right T-Drill bit. Tianhe's drill bits are engineered with precision and durability, allowing you to achieve uniform hole quality with minimal deviation. This level of consistency is essential for meeting tight tolerances and maintaining high-quality standards in your projects.

How Tianhe's Drill Bits Can Enhance Your Project's Results

Tianhe's drill bits are designed to enhance your project's results by delivering superior performance and reliability. With advanced features such as optimized cutting geometries and high-quality materials, these drill bits offer exceptional efficiency and longevity, resulting in cost savings over time. By choosing Tianhe's drill bits, you can elevate the overall quality of your drilling operations while ensuring excellent project outcomes.

Advantages of Tianhe's Drill Tubes

When it comes to drill tubes, Tianhe stands out as the top choice for professionals in the industry. With a reputation for high-quality products and exceptional customer service, Tianhe has become a trusted name in the drilling world.

Why Tianhe is the Top Choice for Drill Tubes

Tianhe's drill tubes are known for their durability, precision, and reliability. With a wide range of options, including tube notchers and T-drills, Tianhe offers solutions for all drilling needs. Their expertise in geotechnical drilling ensures that their products are designed to meet the highest standards.

Tianhe's commitment to innovation sets them apart as a leader in the industry. Their continuous research and development efforts ensure that their drill tubes are equipped with the latest technology, making them more efficient and effective for drilling operations. This dedication to staying ahead of the curve means that when you choose Tianhe for your drill tube needs, you can trust that you will get cutting-edge products to enhance your drilling performance.

The Benefits of Choosing Tianhe for Your Drill Tube Needs

Choosing Tianhe means accessing cutting-edge technology and innovative solutions to enhance drilling projects. Their commitment to quality and performance means that you can trust their drill tubes to deliver consistent results, time after time.

With Tianhe's expertise, you can benefit from improved efficiency and productivity in your drilling operations, ultimately saving time and costs. Additionally, their dedication to research and development ensures that you will always have access to the latest advancements in drill tube technology, keeping your projects at the forefront of industry standards.

How Tianhe's Expertise Can Elevate Your Drilling Project

With years of experience in the industry, Tianhe understands the unique challenges that come with drilling projects. Their team of experts is dedicated to providing personalized support and guidance to help you find the perfect drill tube solution for your specific needs.

By choosing Tianhe as your partner for drill tube solutions, you can be confident that you're getting top-of-the-line products backed by unparalleled expertise and support.

Tianhe is Your Ultimate Partner for Drill Tube Solutions

Making the Right Choice for Your Project's Drill Tube

When selecting the perfect drill tube for your project, Tianhe offers many options to meet your needs. With their expertise in geotechnical drilling, you can trust that they will provide the best solution for your drilling requirements.

Ensuring Success with the Perfect Drill Tube Selection

Choosing the right drill tube is essential for the success of your project. Tianhe's extensive selection of drill tubes, tube notchers, and t-drill systems ensures you can find the perfect match for your drilling needs. Their high-quality products are designed to maximize efficiency and accuracy in every drilling operation.

Tianhe's commitment to excellence and innovation makes it the ultimate partner for all your drill tube solutions. Their dedication to research, design, production, sales, and management sets them apart as a leader in the industry. Trust Tianhe to elevate your drilling project with their top-notch products and expertise.

Tianhe's dedication to excellence extends beyond its products to its customer service. Their team of experienced professionals is committed to providing personalized solutions to meet your specific drilling needs. From initial consultation to after-sales support, Tianhe is with you every step of the way, ensuring a seamless and successful project.