Introduction

When it comes to efficient and precise drilling, down the hole drills are essential tools for various industries. These powerful machines are equipped with key components that make them reliable and effective for various drilling applications. One crucial element in maximizing the performance of down the hole drills is using the right drill bits, which play a significant role in achieving optimal results.

Understanding Down the Hole Drills

Down the hole drills, also known as DTH drills, are specialized equipment designed to bore holes into hard rock formations and other challenging terrains. These drills utilize hammer and drill technology to deliver powerful impact force, making them ideal for demanding drilling tasks.

Down-the-hole drills are essential for various industries, including mining, construction, and oil and gas exploration. Their ability to bore through tough rock formations with precision and efficiency makes them indispensable tools for these sectors. Additionally, DTH drills can reach greater depths than other drilling methods, allowing for more extensive exploration and resource extraction.

Key Components of Down the Hole Drills

Down-the-hole (DTH) drills are powerful machines used to create deep holes in hard rock formations. Here are the key components that enable their effective operation:

- Drill Bit: Located at the end of the drill string, the bit makes direct contact with the rock and breaks it into pieces. Different bits are available depending on the specific rock formation being drilled.

- Down-the-Hole Hammer: This critical component sits above the drill bit and utilizes compressed air to deliver rapid, hammering blows that shatter the rock.

- Drill Pipe: These hollow tubes are sequentially added as the hole deepens. They perform multiple functions: transmitting rotation and downward force to the hammer and bit, supplying compressed air to power the hammer, and flushing out the broken rock fragments (cuttings) with pressurized air or water.

The robust combination of a drill bit, down-the-hole hammer, and drill pipes allows DTH rigs to penetrate even the toughest rock formations efficiently.

Using the right drill bits is crucial for achieving optimal drilling performance. Different drill bits are designed for specific rock formations, so selecting the appropriate bit ensures efficient and effective drilling. Additionally, using the right drill bit can help minimize wear and tear on both the bit and the hammer, ultimately extending the lifespan of these critical components. By investing in high-quality, properly matched drill bits, operators can maximize productivity and minimize downtime due to equipment failure.

Importance of Using the Right Drill Bits

Choosing the right drill bit is essential for any drilling project. Not only will it impact the quality and efficiency of your work, but it can also affect safety and project costs. Here are some key reasons why using the right drill bit matters:

- Material Compatibility: Different drill bits are designed for specific materials. Diamond-tipped bits excel in hard rock, while wood bits work best in softer materials. Using the wrong bit can damage the material, dull the bit quickly, and hinder progress.

- Efficiency and Clean Holes: The right drill bit will cut through the material cleanly and efficiently. The wrong bit can cause chipping and breakage and require more effort to drill through the material.

- Safety: Using a dull or improper drill bit increases the risk of the bit binding or breaking, which can lead to injury. The right bit ensures a smooth drilling process and reduces safety hazards.

Selecting the appropriate drill bit for your project is a worthwhile investment that ensures a successful outcome, saves time and money, and prioritizes safety.

How Down the Hole Drills Work

Down the hole drills are powerful machines that use drill bits to penetrate hard rock and soil for various industrial applications. The process of drilling with a DTH drill involves the drill bit being attached to the end of a drill string, which is then driven into the ground by a combination of hammer and drill technology. This method allows for efficient and precise drilling, making it an essential tool in mining, construction, and quarrying operations.

The Process of Drilling with a DTH Drill

When using a down the hole drill, the hammer is located behind the bit inside the hammer drill. Compressed air is forced down through the hammer, it strikes the piston inside, creating a powerful impact that drives the bit into the rock or soil. This process results in faster penetration rates and straighter holes than other drilling methods, making DTH drills highly effective in challenging geological conditions.

Utilizing Hammer and Drill Technology

The combination of hammer and drill technology in DTH drills ensures that energy is efficiently transferred from the compressor to the bit, maximizing drilling performance. This innovative design allows for greater control over drilling speed and depth, allowing for adjustment according to specific ground conditions. With Tianhe’s advanced engineering expertise, their down-the-hole drills are optimized for superior performance and reliability.

Advantages of Tianhe Down the Hole Drills

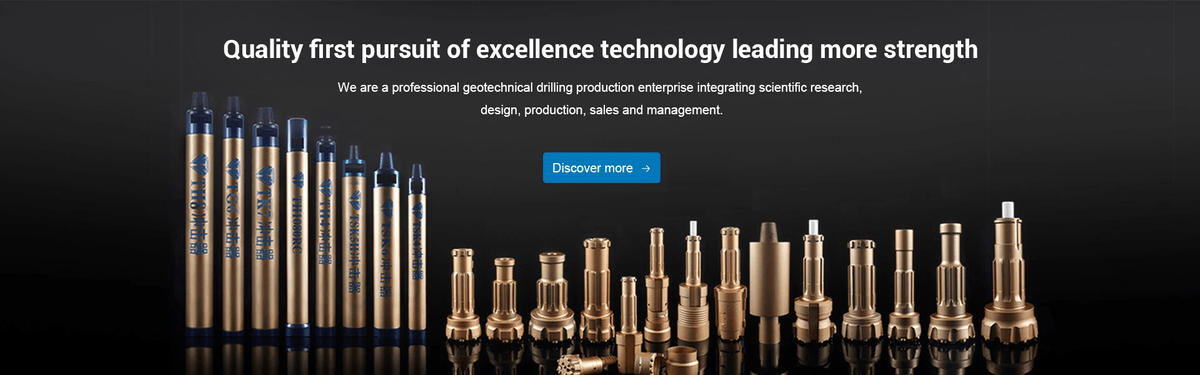

Tianhe down the hole drills are renowned for their superior performance and innovative design. They offer a multitude of advantages that make them a top choice for drilling professionals around the world. Here are some key benefits:

- High Efficiency: Tianhe's drills are engineered to maximize productivity, allowing you to complete drilling projects faster and more cost-effectively.

- Precision Drilling Capabilities: Achieve exceptional accuracy with Tianhe's advanced drilling technology, ensuring consistent and reliable results for every hole.

- Exceptional Durability: Built with demanding environments in mind, Tianhe's drills offer long-lasting performance and minimal downtime, keeping your operations running smoothly.

Tianhe's commitment to quality and cutting-edge technology ensures that you get reliable down the hole drilling solutions built to perform in even the most challenging conditions. For more information on how Tianhe's down the hole drills can benefit your specific needs, contact us today.

Selecting the Right Drill Bits

Types of Drill Bits for Different Applications

When it comes to drilling, selecting the appropriate drill bit is essential for achieving clean, efficient holes. A wide variety of drill bits are available, each designed to tackle specific materials and applications. Here's a breakdown of some common types to help you pick the perfect bit for your drilling project:

- Twist Drill Bits: These versatile workhorses are ideal for general-purpose wood, metal, and plastic drilling. Their spiral flute design aids in chip removal, keeping the hole clear and preventing overheating.

- Masonry Drill Bits: These bits, featuring a tough tungsten carbide tip, excel at drilling hard materials like concrete, brick, and stone. Their robust design allows them to withstand the hammering action of a hammer drill.

- Wood Drill Bits: This category encompasses various specialized wood drill bits, such as brad point bits for clean holes and spade bits for fast, large-diameter cuts.

- Specialty Drill Bits: Numerous specialty drill bits are available for unique applications. Hole saws create large-diameter holes in wood or metal, while glass and tile bits ensure clean cuts in fragile materials.

Understanding the distinct functionalities of these drill bit types will equip you to confidently tackle any drilling project.

Factors to Consider When Choosing Drill Bits

When tackling a drilling project, choosing the right drill bit is crucial for a clean, efficient job. Here are some key factors to consider:

- Material: The most important factor is the type of material you're drilling into. Different materials have varying hardness and require specific drill bit designs to optimize drilling and prevent damage. For instance, soft materials like wood require bits that facilitate fast penetration, while hard materials like concrete necessitate heavy-duty bits that can endure wear and tear.

- Hole Size: Drill bits come in a wide range of diameters to create holes of various sizes. Select a bit that matches your desired hole dimension for a precise fit.

- Drilling Depth: Consider the required depth of the hole. Standard drill bits work well for shallow holes, but deeper drilling might necessitate longer bits to reach the desired depth.

- Impact and Speed: Some projects involve high-impact drilling or require specific rotation speeds. Understanding your project's necessary force and speed will help you select a drill bit designed to handle those demands without compromising performance or safety.

By considering these factors, you can choose the ideal drill bit for your project and ensure a smooth and successful drilling experience.

Ensuring Efficiency and Safety with the Right Drill Bit

Using the right drill bit ensures efficiency in drilling operations and plays a significant role in safety. A well-suited drill bit minimizes wear and tear on equipment, reduces downtime for maintenance, and ultimately enhances overall productivity. Furthermore, selecting a drill bit that matches your specific drilling requirements will contribute to safer working conditions by preventing potential hazards from using an ill-fitted tool.

The Role of Hammer Drills

Hammer drills play a crucial role in the drilling process, as they combine rotary drilling with hammering action to break through tough surfaces. This dual functionality allows for faster and more efficient drilling, making them ideal for various construction, mining, and quarrying applications.

Understanding the Function of a Hammer Drill

A hammer drill creates a rapid hammering action while rotating the drill bit, enabling it to penetrate hard materials such as concrete and masonry. This unique mechanism significantly reduces the effort required to drill through tough surfaces, making it an essential tool for professionals in the construction and mining industries.

The Benefits of Using a Hammer Drill

Hammer drills are a game-changer for DIYers and professionals alike. Here's why:

- Effortless Penetration: Unlike standard drills, hammer drills conquer tough materials like concrete, brick, and stone. Their hammering action pulverizes the material while the bit rotates, creating clean holes with impressive speed.

- Enhanced Precision: The hammering mechanism provides superior control, preventing the bit from wandering and ensuring your holes are exactly where you need them.

- Reduced Fatigue: Drilling through hard materials can be tiring. Hammer drills minimize the effort required, thanks to the hammering action that does the heavy lifting. This translates to less user fatigue and allows you to accomplish more in a shorter amount of time.

With a hammer drill in your toolbox, you can confidently tackle challenging projects. They are an essential tool for efficient and accurate drilling in tough materials.

Tianhe’s Advanced Hammer Drill Technology

Tianhe's advanced hammer drill technology sets the standard for performance and reliability. With innovative features designed to enhance durability and productivity, it is engineered to withstand demanding work environments while delivering exceptional results.

Maintenance and Care for Down the Hole Drills

When it comes to maintaining down the hole drills, several best practices can help prolong their lifespan. Regularly cleaning and lubricating the drill components and storing them in a dry and secure environment can prevent corrosion and damage. Additionally, following manufacturer guidelines for maintenance schedules and procedures ensures optimal performance.

Best Practices for Prolonging Drill Lifespan

Keeping your drill in top condition is key to avoiding downtime and getting the job done efficiently. Here are some best practices to follow for extending the lifespan of your drill:

- Regular Inspections and Maintenance: Schedule regular inspections to check for signs of wear and tear on all parts of your drill, including the chuck, cords, brushes, and any attachments you frequently use. Replace worn-out components promptly to prevent further damage.

- Prevent Overheating: Avoid putting excessive strain on your drill by using the appropriate drill bit for the material and applying the correct pressure. Take breaks during extended use to allow the motor to cool down.

- Keep it Clean: Regularly clean your drill to remove dust, dirt, and debris that can build up and hinder performance. Wipe down the exterior and use a compressed air can to remove dust from vents and internal components.

- Store it Properly: When not used, store your drill in a clean, dry place away from extreme temperatures. This will help prevent rust and corrosion.

By following these simple tips, you can ensure your drill operates smoothly and efficiently for years.

Importance of Regular Inspections and Maintenance

Regular inspections and maintenance are essential for keeping your down-the-hole drills running smoothly, efficiently, and most importantly, safely. Here's how a proactive approach can benefit you:

- Prevent Costly Breakdowns: By catching minor issues early through inspections, you can address them before they become major repairs or even complete equipment failures. This will save you significant time and money in the long run.

- Ensure Safe Operation: Worn or damaged drill components can pose safety hazards. Regular inspections help identify these risks before they lead to accidents or injuries.

- Maintain Drilling Efficiency: Properly maintained drills operate at optimal performance. This translates to faster drilling times and improved productivity.

Incorporating regular inspections and maintenance into your down-the-hole drill operation is an investment that pays off in terms of safety, efficiency, and cost savings.

Tianhe’s Commitment to Quality and Durability

At Tianhe, we take pride in our commitment to providing high-quality down the hole drills that are built to last. Our drills undergo rigorous testing and quality control measures to ensure durability under demanding drilling conditions. With a focus on precision engineering and advanced materials, our drills are designed to withstand heavy use while delivering exceptional performance.

Our commitment to quality and durability extends beyond the design and construction of our drills. We also prioritize ongoing research and development to stay at the forefront of drill technology. This dedication to innovation ensures that our customers benefit from the latest advancements in drilling equipment, allowing them to tackle even the most challenging projects with confidence. By continuously improving our products, we demonstrate our unwavering commitment to providing reliable, high-performance drills that meet the evolving needs of the industry.

Advancements in Drill Technology

In recent years, there have been remarkable innovations in hammer drill design that have revolutionized the drilling industry. These advancements include the development of more powerful and efficient hammer drills that can handle a wider range of drilling applications. With improved technology, modern hammer drills can now deliver higher impact energy and faster drilling speeds, making them indispensable tools for various drilling projects.

Innovations in Hammer Drill Design

One key innovation in hammer drill design is the integration of advanced materials and engineering techniques to create lighter yet more durable drills. This has reduced operator fatigue and increased productivity on job sites. Additionally, manufacturers have focused on enhancing the ergonomics of hammer drills, ensuring that they are comfortable to use for extended periods without compromising performance.

Future Trends in Down the Hole Drilling

Future trends in down the hole drilling are expected to focus on further improving drill bit technology to enhance penetration rates and overall drilling efficiency. There is also a growing emphasis on developing environmentally friendly drilling solutions that minimize waste and reduce environmental impact. As technology evolves, we can anticipate more automation and digital integration in down the hole drilling equipment, leading to greater precision and control.

Tianhe's Leadership in Industry Research and Development

Tianhe has been at the forefront of industry research and development, consistently pioneering new technologies and setting new standards for down the hole drills. With a dedicated team of engineers and researchers, Tianhe continues to push boundaries by investing heavily in R&D efforts to create cutting-edge solutions for today's drilling challenges. Their commitment to innovation ensures that customers benefit from state-of-the-art equipment that delivers exceptional performance while prioritizing safety and sustainability.

Tianhe's commitment to staying ahead of the curve is evident in its proactive approach to anticipating industry trends and customer needs. By closely monitoring market demands and emerging technologies, Tianhe can adapt quickly and efficiently, ensuring its products remain at the forefront of innovation. This forward-thinking mindset allows them to consistently deliver cutting-edge solutions that meet current drilling challenges and anticipate future requirements, giving their customers a competitive edge in the market.

Ensure Safety and Efficiency in Drilling Operations

When choosing the right equipment for your drilling needs, it's essential to consider the efficiency and safety of your operations. By selecting high-quality down the hole drills and drill bits, you can ensure optimal performance and longevity. Partnering with Tianhe for reliable drilling solutions guarantees access to advanced technology and durable equipment that will meet your specific requirements.

Choosing the Right Equipment for Your Drilling Needs

Choosing the right down-the-hole (DTH) drill and drill bits is essential for an efficient and successful drilling project. Tianhe Drilling Solutions offers a comprehensive selection of equipment to suit various applications. Here are some key factors to consider when selecting your drilling equipment:

- Project Purpose: Identify the specific purpose of your drilling project. Are you performing mineral exploration, water well drilling, or construction site prep work? Different applications require different drilling methods and equipment.

- Hole Size and Depth: Consider the required diameter and depth of the borehole you need to create. This will influence the size and power of the drill rig you'll need.

- Ground Conditions: The type of soil or rock you'll be drilling through plays a crucial role. Different drilling methods are better suited for hard rock, soft soil, or unconsolidated materials.

- Budget: Drilling equipment can cost significantly. Tianhe can help you find equipment that delivers optimal performance within your budgetary constraints.

Consider these factors to ensure you select the most appropriate drilling equipment for your project. Tianhe Drilling Solutions' expertise and diverse equipment selection can help you achieve optimal drilling performance. Contact Tianhe today to discuss your needs and find the perfect drilling solution for your next project.

Safety should always be a top priority in any drilling operation. You can ensure efficient and safe drilling practices by utilizing high-quality hammer drills and drill bits. Tianhe's commitment to quality and durability means their equipment is built to withstand rigorous use while maintaining safety standards, providing peace of mind during operations.

Partnering with Tianhe for Reliable Drilling Solutions

Tianhe's dedication to providing reliable drilling solutions makes it an ideal partner for all your drilling needs. Their advanced technology, innovative designs, and industry-leading research and development ensure that you have access to cutting-edge equipment that will enhance your operations' productivity and efficiency.

With Tianhe as your partner, you can rest assured that their commitment to quality and reliability will translate into cost savings and improved performance for your drilling operations. Their team of experts is dedicated to providing exceptional customer service, ensuring you receive the support and guidance needed to maximize the benefits of their cutting-edge equipment. By partnering with Tianhe, you are not just investing in equipment; you are investing in a long-term relationship with a trusted industry leader.