Introduction

Are you ready to take your drilling operations to the next level? DTH drilling, also known as down the hole hammer drilling, is a cutting-edge technique that offers numerous advantages over conventional methods. By utilizing DTH hammers, you can achieve faster penetration rates and higher productivity in rock drilling projects.

What is DTH Drilling?

DTH drilling involves using a downhole hammer to create a hole in the earth's crust for various purposes, such as mining, construction, and geothermal exploration. This innovative method allows precise and efficient drilling in even the toughest rock formations.

Benefits of DTH Drilling

DTH (Down-The-Hole) drilling offers several advantages over traditional drilling methods, making it a valuable tool for various excavation projects. Here's a breakdown of its key benefits:

- Enhanced Speed and Accuracy: DTH drilling boasts superior speed due to its efficient hammering mechanism. Additionally, it minimizes deviations from the intended trajectory, reducing the need for corrective measures and saving time and resources.

- Improved Rock Penetration: DTH hammers deliver exceptional energy transfer and impact force, enabling faster and more effective penetration through tough rock formations. This makes DTH drilling ideal for deep drilling projects and applications requiring robust rock excavation.

- Versatility: DTH drilling can handle various rock types, from soft to extremely hard. This versatility makes it a suitable option for various geological conditions, eliminating the need to switch between different drilling methods.

- Reduced Environmental Impact: Compared to traditional rotary drilling methods, DTH drilling uses less water and produces fewer cuttings, minimizing its environmental footprint.

In conclusion, DTH drilling proves to be a valuable asset for various excavation projects due to its speed, accuracy, rock penetration capabilities, and environmental advantages.

Maximizing Productivity with DTH Drilling

DTH drilling is unmatched when it comes to maximizing productivity in rock drilling projects. By leveraging the power of downhole hammer technology, you can achieve higher levels of efficiency and ultimately complete your projects in less time—saving both time and money.

The Basics of DTH Drilling

DTH drilling technology uses a down-the-hole hammer to drill into rock formations. This innovative method allows for faster and more efficient drilling than traditional methods. By utilizing DTH hammers, operators can achieve higher penetration rates and increased productivity.

DTH Drilling Technology

DTH drilling technology involves using a pneumatic hammer to create a borehole in rock formations. The hammer is fitted with drill bits that pulverize the rock, allowing for deeper and more precise drilling. Due to its speed and accuracy, this method is widely used in mining, construction, and geotechnical projects.

DTH drilling technology offers several advantages over conventional drilling methods. Firstly, it allows for faster and more efficient drilling, which is crucial in mining industries where time is of the essence. Additionally, DTH drilling produces less waste material, resulting in cost savings and reduced environmental impact. Furthermore, the precision of DTH drilling reduces the need for additional work to correct errors, saving both time and money in the long run.

Comparing DTH Drilling to Conventional Methods

Compared to conventional drilling methods, DTH drilling offers significant advantages in terms of speed and efficiency. Traditional methods, such as rotary drilling, often struggle with hard rock formations, leading to slower progress and increased wear on equipment. In contrast, DTH drilling excels in penetrating tough formations with minimal downtime.

Furthermore, DTH drilling allows for more precise control over the drilling process, resulting in better accuracy and reduced risk of deviation from the desired path. This level of precision is especially crucial in projects that require specific angles or depths to be reached. Maintaining accuracy throughout the drilling process can save time and resources, making DTH drilling a highly efficient option for various applications.

Advantages of Using DTH Hammers

DTH hammers offer a range of benefits that make them a valuable asset in various drilling applications. Here's how they stand out:

- Superior Hole Quality: DTH hammers produce straighter holes with minimal deviation. This is crucial in mining for precise blasting and in construction for accurate structure placement.

- Faster Completion and Reduced Costs: Their efficient drilling process allows quicker project turnaround times and lower operational costs.

- Enhanced Adaptability: The ability to rapidly switch drill bits during operation ensures smooth progress even in challenging drilling conditions.

- Improved Hole Cleaning: DTH hammers effectively remove cuttings and debris from the borehole, preventing blockages and ensuring a reliable drilling process.

DTH hammers provide a powerful combination of speed, accuracy, and efficiency, making them a preferred choice for various demanding drilling projects.

Choosing the Right Equipment

Selecting the best DTH hammer is crucial when choosing the right equipment for your DTH drilling project. The type of rock you'll be drilling into, as well as the depth and diameter of the borehole, will all influence your choice. Factors such as air pressure and consumption, as well as the size and weight of the hammer, should also be considered.

Selecting the Best DTH Hammer for Your Project

Selecting the right DTH hammer is crucial for efficient and successful drilling. Here's a breakdown of key factors to consider:

1. Project Requirements

- Drilling conditions: High-performance hammers are needed for hard rock, while versatile options work for various formations.

2. Hole Specifications

- Depth and Diameter: Deeper or wider holes necessitate a larger and more powerful DTH hammer.

Tianhe's diverse range of DTH hammers caters to these factors, offering a perfect fit for your drilling needs.

You can select the ideal Tianhe DTH hammer to ensure optimal drilling performance by carefully considering your project requirements and hole specifications.

Understanding DTH Hammer Specifications

Understanding DTH hammer specifications is essential for making an informed decision. Key specifications include piston diameter, impact rate, and operating pressure. These factors will directly impact drilling performance and efficiency, so it's important to understand how they relate to your project requirements. The material used in constructing the DTH hammer should also be considered, as it can affect durability and longevity. Moreover, examining the design and layout of the hammer can provide insights into its suitability for different drilling conditions and environments.

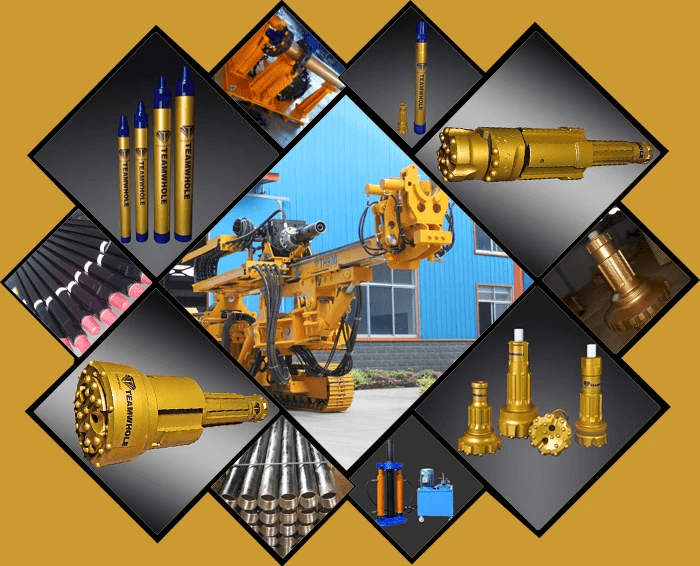

Exploring Tianhe's Range of DTH Hammers

Tianhe's DTH hammers range includes various models catering to different drilling needs. There is a diverse selection, from low-pressure hammers suitable for soft formations to high-pressure hammers designed for hard rock drilling. Each hammer is engineered with precision and durability, ensuring reliable performance in challenging drilling environments.

Optimizing Drill Performance

When it comes to optimizing drill performance, DTH drilling offers a range of best practices that can be implemented to ensure maximum efficiency and productivity. Project managers can achieve superior results and minimize downtime by utilizing the latest technology and techniques in rock drilling.

Implementing Best Practices for DTH Drilling

Implementing best practices for DTH drilling involves thorough planning and execution of drilling operations. This includes proper operator training, regular equipment maintenance, and adherence to safety protocols. By following these practices, companies can minimize the risk of downtime and ensure smooth operations throughout the project.

Implementing best practices for DTH drilling involves training operators and maintaining equipment, as well as utilizing advanced technology and tools to increase efficiency. This can include using real-time data monitoring systems to make quick adjustments during drilling operations and implementing automated drilling processes to streamline the workflow. By embracing these technological advancements, companies can significantly improve their drilling productivity and achieve better project outcomes.

Increasing Efficiency in Rock Drilling

To increase efficiency in rock drilling, it's essential to leverage the capabilities of down the hole hammer drilling technology. This method allows for faster penetration rates and better precision, resulting in higher productivity and cost savings. By using DTH hammers, companies can significantly improve their overall drilling performance.

Leveraging down the hole hammer drilling technology also minimizes the risk of deviation, ensuring that the drill stays on course and reaches the desired depth accurately. This reduces the need for costly corrections and re-drilling, saving time and money in the long run. Additionally, DTH hammers are designed to handle a wide range of rock formations, making them versatile tools for various drilling applications.

Utilizing Innovative Techniques for Down the Hole Hammer Drilling

Innovative techniques such as advanced hole cleaning systems and optimized drill bit designs can further enhance down the hole hammer drilling performance. These techniques help to reduce wear on equipment, improve penetration rates, and ultimately maximize productivity on site.

In addition to hole-cleaning systems and optimized drill bit designs, real-time data monitoring and analysis is another innovative technique for enhancing down-the-hole hammer drilling performance. Operators can use advanced sensors and software to track real-time drilling parameters such as pressure, rotation speed, and vibration. This allows for immediate adjustments to optimize drilling performance, minimize downtime, and reduce the risk of equipment failure. Real-time data monitoring also provides valuable insights for future drilling operations, contributing to overall efficiency and cost savings.

Maintenance and Safety Measures

Extending the Lifespan of DTH Hammers

Regular maintenance is crucial to extending the lifespan of DTH hammers. Proper cleaning and lubrication of the hammer drill can prevent premature wear and tear. Additionally, following manufacturer guidelines for regrinding and sharpening worn-out bits is essential to ensure optimal performance.

Ensuring Safety in DTH Drilling Operations

Safety is paramount in rock drilling operations, especially when using downhole hammer equipment. Thorough risk assessments must be conducted before drilling activities commence. Comprehensive training on the safe use of downhole hammers and the wearing of appropriate personal protective equipment are vital safety measures.

Following Maintenance Guidelines from Tianhe

Tianhe provides comprehensive maintenance guidelines for their range of DTH hammers to help users maximize their lifespan and performance. Following these guidelines diligently can prevent unexpected downtime due to equipment failure and ensure that your DTH drilling operations run smoothly.

Improving Project Management

Efficiency is key to streamlining operations with DTH drilling. Project managers can ensure that their operations run smoothly and effectively by utilizing the latest down-the-hole hammer drilling technology. With DTH hammers, rock drilling becomes faster and more precise, allowing for better project management and quicker task completion.

Streamlining Operations with DTH Drilling

DTH drilling offers a streamlined approach to rock drilling, allowing for faster penetration rates and reduced downtime. This means that project managers can oversee operations more effectively, knowing they have reliable equipment. With DTH hammers, projects can be managed with greater efficiency and productivity, ultimately leading to successful outcomes.

Enhancing Productivity in Geotechnical Drilling

In geotechnical drilling, productivity is essential for meeting project deadlines and delivering high-quality results. By incorporating downhole hammer technology into geotechnical drilling operations, project managers can enhance productivity by achieving deeper boreholes in less time. This improves overall project management and ensures that geotechnical objectives are met efficiently.

Maximizing ROI with DTH Hammer Wikipedia

Maximizing return on investment (ROI) is a key aspect of project management, and DTH hammers play a crucial role in achieving this goal. By increasing drilling efficiency and reducing operational costs, DTH hammers contribute to maximizing ROI on projects. By investing in DTH hammer Wikipedia technology, project managers can ensure their resources are utilized optimally for the best possible outcomes.

Partner with Tianhe for Successful DTH Projects

DTH drilling has revolutionized rock drilling, providing superior results and unmatched efficiency. Embracing innovation in rock drilling is essential for staying ahead in the industry, and partnering with Tianhe ensures successful DTH projects. Our range of DTH hammers and expertise guarantees exceptional outcomes for all your drilling needs.

Achieving Superior Results with DTH Drilling

DTH drilling delivers unparalleled results, maximizing productivity and efficiency in every project. The advanced technology of down the hole hammer drilling ensures precise and powerful rock penetration, making it the preferred choice for geotechnical drilling operations.

Embracing Innovation in Rock Drilling

Innovation is key to success in the ever-evolving field of rock drilling. DTH hammers have transformed the industry by offering faster penetration rates and reduced downtime, making them an innovative solution for all your drilling requirements.

Tianhe is a trusted partner for successful DTH projects. We offer high-quality DTH hammers designed to meet your specific needs. Our expertise and commitment to excellence ensure that your projects are completed efficiently and cost-effectively.