Introduction

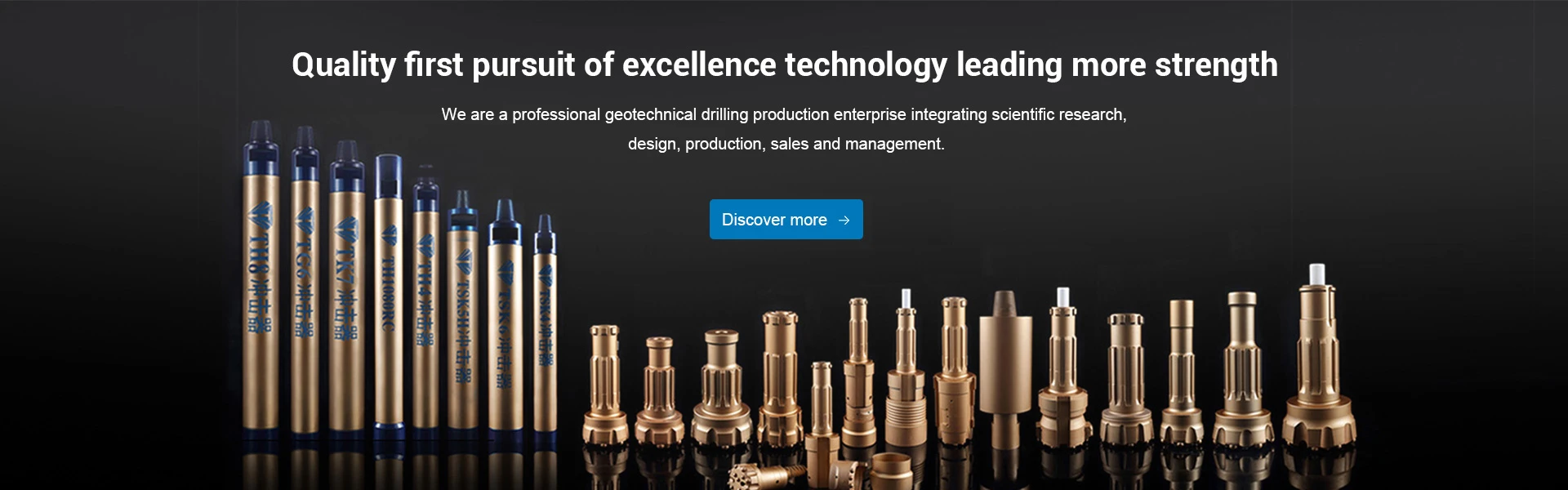

Are you familiar with down the hole hammer drilling? This innovative technique involves using a down the hole hammer to drill through rock, making it an essential tool in geotechnical drilling. Maximizing efficiency in DTH hammer operations is crucial for achieving optimal results, and that's where Tianhe comes in.

Understanding Down the Hole Hammer Drilling

Down the hole hammer drilling, or DTH drilling, is a method of drilling boreholes into hard rock formations. It involves a pneumatic hammer that delivers powerful blows to the drill bit, allowing for efficient and precise drilling. This technique is widely used in mining, construction, and geotechnical exploration.

Importance of Maximizing Efficiency in DTH Hammer

Maximizing efficiency in DTH (Down-the-Hole) hammer operations is crucial for several reasons, particularly in mining, construction, and geotechnical engineering industries. Here's why it's important to focus on efficiency in DTH hammer usage:

- Cost Reduction: Efficiency improvements in DTH hammer operations directly reduce costs. By completing drilling tasks more quickly and with fewer resources, companies can minimize operational expenses, including labor, fuel, and equipment maintenance costs.

- Time Savings: Time is a valuable resource in any industry, and maximizing efficiency in DTH hammer operations helps save time by reducing drilling cycle times and increasing overall productivity. This allows projects to be completed faster, accelerating project timelines and potentially leading to earlier project completion and revenue generation.

- Increased Productivity: Efficient DTH hammer usage leads to higher productivity levels, allowing for the completion of more drilling tasks within a given timeframe. This increased productivity can translate into higher project throughput, increased output, and greater profitability for companies operating in drilling-intensive industries.

- Optimized Resource Utilization: Efficiency improvements in DTH hammer operations enable better utilization of resources, including drilling rigs, personnel, and consumables such as drill bits and drilling fluids. By optimizing resource allocation and minimizing downtime, companies can maximize the return on their investments in equipment and manpower.

- Enhanced Safety: Efficient DTH hammer operations can improve safety outcomes by reducing workers' time in hazardous drilling environments. Minimizing drilling cycle times and streamlining operational processes can help mitigate risks associated with drilling activities, enhancing worker safety and reducing the likelihood of accidents or injuries.

- Environmental Impact Reduction: Maximizing efficiency in DTH hammer operations can have positive environmental implications by reducing the overall environmental footprint of drilling activities. By completing drilling tasks more quickly and with fewer resources, companies can minimize disturbance to sensitive ecosystems, reduce emissions associated with drilling equipment, and conserve natural resources.

- Competitive Advantage: Companies prioritizing efficiency in DTH hammer operations can gain a competitive edge in the marketplace. By offering faster turnaround times, higher productivity levels, and lower costs than competitors, these companies can attract more clients, secure larger contracts, and position themselves as industry leaders.

- Continuous Improvement: Focusing on efficiency encourages a culture of continuous improvement within organizations. By regularly evaluating and optimizing DTH hammer operations, companies can identify areas for improvement, implement best practices, and drive ongoing performance enhancements across their drilling operations.

Maximizing efficiency in DTH hammer operations is essential for cost reduction, time savings, increased productivity, optimized resource utilization, enhanced safety, reduced environmental impact, competitive advantage, and continuous improvement. By prioritizing efficiency, companies can achieve greater operational effectiveness, profitability, and sustainability in drilling-intensive industries.

Meet Tianhe: The Expert in Geotechnical Drilling

Tianhe is a professional geotechnical drilling manufacturer specializing in research, design, production, sales, and management of DTH hammers. With a focus on innovation and quality, Tianhe offers premium DTH hammers engineered for superior performance and longevity.

Choosing the Right DTH Hammer

When selecting a DTH hammer for your drilling operations, it's crucial to consider factors such as the type of rock formation you'll be drilling into, the required hole diameter, and the depth of the borehole. Center Rock Inc.'s DTH hammers are known for their durability, reliability, and superior performance in various drilling conditions. With Tianhe's premium DTH hammers, you can maximize efficiency and productivity in your geotechnical drilling projects.

Factors to Consider When Selecting a DTH Hammer

Selecting the right DTH (Down-the-Hole) hammer is crucial for achieving optimal drilling performance, efficiency, and cost-effectiveness. Several factors should be considered when making this decision. Here are some key factors to consider:

- Application Requirements: Evaluate the specific drilling application and requirements, including the type of rock or formation to be drilled, the desired hole diameter and depth, and any special drilling conditions or challenges. Different DTH hammer models are designed for various applications, such as mining, construction, quarrying, or geotechnical exploration.

- Hammer Size and Compatibility: Choose a DTH hammer size and design that are compatible with the drilling rig and other equipment being used. Consider the rig's drilling capacity, hydraulic system capabilities, and mounting configuration to ensure seamless integration and optimal performance.

- Drilling Parameters: Consider the drilling parameters required for the application, including air pressure, air volume, rotation speed, and penetration rate. Select a DTH hammer model that can operate effectively within the desired drilling parameters while achieving the required depth and productivity levels.

- Hammer Design and Construction: Evaluate the design, construction, and materials used in the DTH hammer to ensure durability, reliability, and longevity. Look for hammers with robust construction, high-quality materials, and advanced engineering features that can withstand the rigors of drilling in challenging conditions.

- Performance and Efficiency: Assess the performance characteristics of the DTH hammer, including energy transfer efficiency, impact force, and drilling speed. Choose a hammer model that offers high drilling efficiency, consistent performance, and optimal penetration rates, resulting in faster drilling and increased productivity.

- Maintenance and Serviceability: Consider the ease of maintenance and serviceability of the DTH hammer, including access to internal components, availability of spare parts, and manufacturer support. Select a hammer model designed for easy maintenance, with accessible service points and comprehensive technical support from the manufacturer or distributor.

- Cost and Value: Evaluate the initial cost and the long-term value and return on investment (ROI) provided by the DTH hammer. Consider factors such as durability, reliability, maintenance requirements, and overall performance when assessing the cost-effectiveness of different hammer models.

- Environmental Considerations: Take into account any environmental regulations or restrictions that may apply to the drilling operation, such as noise, vibration, or emissions limits. Choose a DTH hammer that complies with relevant environmental standards and minimizes the impact on surrounding communities and ecosystems.

By carefully considering these factors and conducting thorough research, drilling operators can select the most suitable DTH hammer for their specific needs, ensuring optimal performance, efficiency, and cost-effectiveness in drilling operations.

Benefits of Using Center Rock Inc's DTH Hammers

Center Rock Inc. is renowned for manufacturing high-quality DTH hammers that deliver exceptional results in down-the-hole hammer drilling applications. Their innovative designs and advanced engineering ensure maximum impact energy transfer to the drill bit, resulting in faster penetration rates and reduced fuel consumption. You can achieve higher productivity and lower operating costs while maintaining superior drilling performance by using Center Rock Inc's DTH hammers.

Maximizing Efficiency with Tianhe's Premium DTH Hammers

Tianhe specializes in producing premium DTH hammers engineered for optimal efficiency and durability in geotechnical drilling operations. Their advanced manufacturing processes and strict quality control measures ensure that each DTH hammer delivers consistent performance and longevity in challenging drilling environments. With Tianhe's premium DTH hammers, you can maximize operational efficiency while minimizing downtime, ultimately enhancing overall project productivity.

In addition to their exceptional performance, Tianhe's premium DTH hammers are designed for easy maintenance and care. With user-friendly features and clear maintenance guidelines, you can ensure that your DTH hammer remains in top condition for extended periods. This means less time spent on repairs and upkeep, allowing your team to focus on the task without unnecessary interruptions.

Proper Maintenance and Care

Regular Inspections and Cleaning for DTH Hammers

Regular inspections and cleaning are crucial to ensure the longevity and optimal performance of your down the hole hammer. Center Rock Inc.'s DTH hammers are built to withstand tough drilling conditions, but inspecting for wear and tear, cleaning out debris or obstructions, and lubricating moving parts are essential. Tianhe recommends conducting thorough inspections after each use to catch potential issues early on.

Best Practices for Extending DTH Hammer Lifespan

Extending the lifespan of DTH (Down-the-Hole) hammers is essential for reducing downtime, minimizing maintenance costs, and maximizing drilling efficiency. Here are five best practices to achieve this:

- Proper Maintenance and Inspection: Regular maintenance and inspection routines are critical for preserving the longevity of DTH hammers. Implement a maintenance schedule that includes cleaning, lubrication, and inspection of seals, o-rings, and wear parts. Promptly replace worn or damaged parts to prevent further deterioration and potential failure.

- Optimized Drilling Parameters: Operating DTH hammers within recommended drilling parameters helps prevent unnecessary wear and tear. Ensure that drilling parameters such as air pressure, rotation speed, and penetration rate are optimized for the specific geological conditions and drilling requirements. Avoid excessive force or over-drilling, accelerating wear on hammer components.

- Proper Handling and Storage: Handle DTH hammers carefully during transportation, installation, and removal to prevent damage to sensitive components. Use appropriate lifting equipment and follow manufacturer guidelines for safe handling practices. Store DTH hammers in a clean, dry environment away from contaminants and corrosive substances to preserve their integrity between uses.

- Use High-Quality Drill Bits: The selection of high-quality drill bits is crucial for extending the lifespan of DTH hammers. Choose drill bits compatible with the hammer's size and design, and ensure they are made from durable materials such as tungsten carbide. Proper bit selection and maintenance help reduce wear on the hammer and improve drilling efficiency.

- Monitor Performance and Troubleshoot Issues: Regularly monitor the performance of DTH hammers during drilling operations to identify any signs of wear, inefficiency, or abnormal behavior. Implement a monitoring system that tracks key performance indicators such as penetration rate, air consumption, and vibration levels. Promptly address any issues that arise and conduct root cause analysis to prevent recurrence.

By implementing these best practices, drilling operators can prolong the lifespan of DTH hammers, reduce the frequency of maintenance interventions, and optimize drilling efficiency, ultimately leading to cost savings and improved productivity.

Tianhe's Recommendations for DTH Hammer Maintenance

Tianhe understands the importance of proper maintenance in maximizing efficiency in down the hole hammer drilling operations. Their expert recommendations for DTH hammer maintenance include following manufacturer guidelines for lubrication schedules, conducting routine pressure testing to ensure consistent airflow, and promptly addressing any signs of wear or damage. Adhering to these recommendations, operators can keep their DTH hammers in peak condition for optimal performance.

In addition to regular maintenance, operators should also invest in high-quality DTH hammer components to ensure long-term durability and reliability. Using genuine parts and components from reputable manufacturers can significantly reduce the risk of premature wear and tear, ultimately saving time and money in the long run. By prioritizing authentic parts, operators can minimize the likelihood of unexpected downtime and maximize the lifespan of their DTH hammers.

Optimizing Drilling Techniques

When it comes to down the hole hammer drilling, efficient drilling strategies are essential for maximizing productivity and minimizing downtime. Center Rock Inc.'s DTH hammers are designed to provide optimal performance in various drilling conditions, allowing operators to achieve precise and fast results. Operators can significantly increase their drilling efficiency and reduce project timelines by utilizing innovative technologies such as advanced percussion systems and durable drill bits.

Efficient Drilling Strategies with DTH Hammer

Choosing the right drilling strategy is crucial for successful down the hole hammer drill operations. Whether using a top hammer or down the hole hammer, understanding the geology of the drilling site is key to determining the most effective approach. Tianhe's team of experts can provide valuable insights into selecting the best drilling strategy based on geological data, ensuring that each project is completed efficiently.

Utilizing Innovative Technologies for Productivity

Innovation plays a vital role in enhancing productivity in down the hole hammer drilling. Center Rock Inc.'s cutting-edge DTH hammers have state-of-the-art features that enable faster penetration rates and longer tool life. By harnessing these innovative technologies, operators can achieve higher productivity levels while maintaining precision and accuracy throughout the drilling process.

Tianhe's Proven Drilling Techniques for Maximum Efficiency

Tianhe has established itself as a leader in geotechnical drilling by developing proven techniques that optimize efficiency in down the hole hammer operations. With decades of experience in research, design, and production, Tianhe offers comprehensive training programs focusing on implementing advanced drilling techniques for maximum efficiency. By leveraging Tianhe's expertise, operators can enhance their skills and improve their DTH hammer drilling performance.

Operators participating in Tianhe's training programs gain a deep understanding of the drilling environment, including the geological and physical characteristics that impact drilling operations. This knowledge allows them to make informed decisions and adjustments during DTH hammer drilling, leading to more precise and efficient outcomes. By honing their understanding of the drilling environment, operators can anticipate challenges and proactively implement strategies to overcome them, ultimately improving overall performance.

Understanding the Drilling Environment

When it comes to down the hole hammer drilling, several factors can affect drilling efficiency. The type of rock or soil being drilled, the depth of the hole, and even the temperature and humidity of the environment can all impact performance. It's crucial to understand these variables to optimize DTH hammer operations.

Factors Affecting Drilling Efficiency

The hardness and abrasiveness of the drilled rock or soil are major factors affecting drilling efficiency with a DTH hammer. Different formations require different types of hammers and bits for optimal performance. Additionally, the depth of the hole plays a role in determining the necessary air pressure and volume for efficient drilling.

Adapting DTH Hammer Operations to Different Conditions

Adapting DTH hammer operations to different conditions is essential for maximizing efficiency. For example, higher air pressure may be necessary in extremely hard rock formations to achieve effective penetration rates. Understanding how to adjust drilling parameters based on varying conditions is key to successful down the hole hammer drilling.

Tianhe's Expert Tips for Navigating Challenging Drilling Environments

As a professional geotechnical drilling manufacturer, Tianhe provides expert tips for navigating challenging drilling environments with DTH hammers. Their team offers guidance on selecting the right equipment and adjusting drilling techniques based on specific geological conditions. Drillers can confidently tackle even the most demanding environments with Tianhe's support.

With Tianhe's expertise, drillers can also benefit from training and skill development programs to enhance their capabilities in navigating challenging drilling environments. The company offers comprehensive training courses that cover the latest drilling techniques, equipment operation, and safety protocols. By investing in continuous skill development, drillers can improve their efficiency and effectiveness in handling complex geological conditions.

Training and Skill Development

Proper training for DTH hammer operators ensures safe and efficient drilling operations. With the complex nature of down the hole hammer drilling, operators need to be well-versed in handling the equipment and understanding the nuances of different drilling environments. This includes knowledge of proper maintenance, troubleshooting, and safety protocols to minimize downtime and maximize productivity.

Importance of Proper Training for DTH Hammer Operators

In the world of down the hole hammer drilling, there's no room for error. Proper training ensures operators understand the equipment they're working with, allowing them to make quick decisions in challenging situations. Well-trained operators are essential for achieving optimal results, from selecting the right DTH hammer for specific geological conditions to implementing efficient drilling techniques.

Enhancing Skills for Enhanced Efficiency

Continuous skill enhancement is key to staying ahead in the ever-evolving field of down the hole hammer drilling. As technology advances and new methods emerge, DTH hammer operators must adapt and refine their skills to maintain high levels of efficiency. This includes staying updated on industry best practices, learning from experienced professionals, and embracing innovative technologies that can streamline drilling processes.

Tianhe's Training Programs for DTH Hammer Operators

Tianhe understands the importance of skilled DTH hammer operators in achieving optimal drilling efficiency. That's why they offer comprehensive training programs to equip operators with the knowledge and skills to excel in geotechnical drilling. From hands-on practical training to theoretical coursework, Tianhe's programs cover all aspects of down the hole hammer operations, ensuring that operators are fully prepared to tackle any drilling challenge.

Partnering with Tianhe for Optimal Drilling Efficiency

Implementing Efficient DTH Hammer Practices

When it comes to down the hole hammer drilling, implementing efficient practices is crucial for maximizing productivity. Center Rock Inc.'s DTH hammers, combined with Tianhe's expertise in geotechnical drilling, offer the perfect solution for achieving optimal efficiency and performance. By choosing the right DTH hammer, following proper maintenance and care, optimizing drilling techniques, understanding the drilling environment, and investing in training and skill development, operators can ensure that they utilize their equipment to its full potential.

The Future of Down the Hole Hammer Drilling

As technology advances, the future of down the hole hammer drilling looks promising. With innovative technologies and equipment enhancements constantly being developed, the efficiency and effectiveness of DTH hammers will only continue to improve. Tianhe is at the forefront of these advancements, constantly researching and developing new solutions to further optimize down-hole hammer drill operations.

Partnering with Tianhe is a game-changer to achieve optimal drilling efficiency with DTH hammers. As a professional geotechnical drilling manufacturer specializing in research, design, production, sales, and management of DTH hammers, Tianhe offers unmatched expertise and support for operators looking to maximize their drilling operations. By partnering with Tianhe, operators can access top-of-the-line equipment and valuable insights and guidance on utilizing their DTH hammers for maximum efficiency.

Partnering with Tianhe also means accessing their extensive industry professionals and experts network. With their connections and resources, operators can stay ahead of the curve regarding new technologies, best practices, and industry trends. This invaluable network can provide operators with the support they need to improve their drilling operations and stay competitive continually.