Introduction

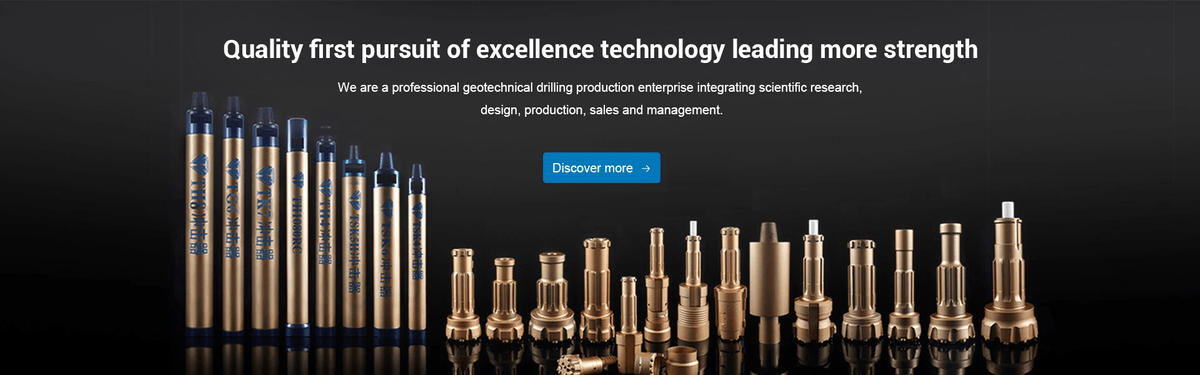

When it comes to efficient ore extraction, the placement of mining drills is crucial. The location and orientation of drilling rigs can significantly impact the quantity and quality of extracted materials. That's where Tianhe comes in - a leader in geotechnical drilling, specializing in research, design, production, sales, and management of innovative drill rigs.

Understanding Mining Drills Placement

Understanding the optimal placement of mining drills involves considering factors such as rock type, ore distribution, and accessibility. It's not just about drilling holes; it's about strategically positioning drill rigs to maximize extraction efficiency and minimize operational costs. By carefully analyzing the geological structure of the mining site, engineers can determine the most effective locations for drill placement, taking into account the density and quality of ore deposits. This level of precision in drill placement can significantly impact the overall productivity and profitability of a mining operation.

Importance of Efficient Ore Extraction

Efficient ore extraction is crucial for several reasons, impacting various aspects of the mining industry and broader society. Here are five key points highlighting its importance:

- Economic Viability: Efficient ore extraction techniques increase the profitability of mining operations by reducing operational costs and increasing the output of valuable minerals. This is essential for the economic viability of mines, particularly those working with low-grade ores. Improved efficiency can make the difference between a mine being economically feasible or not.

- Resource Conservation: By maximizing the amount of metal or mineral extracted from an ore body, efficient extraction methods help in conserving finite natural resources. This is increasingly important as high-grade ore deposits become scarcer, and the industry relies more on lower-grade ores, which require more sophisticated and efficient processing techniques to be economically viable.

- Environmental Impact: Efficient ore extraction and processing techniques can significantly reduce the environmental footprint of mining activities. This includes less waste produced, reduced energy consumption, and lower greenhouse gas emissions. Techniques that allow for the selective extraction of valuable minerals minimize the amount of rock that needs to be moved and processed, thereby reducing the environmental impact.

- Sustainability and Social Responsibility: The mining sector is increasingly under scrutiny from governments, environmental organizations, and the public to operate in a sustainable and socially responsible manner. Efficient extraction methods can help meet these expectations by minimizing land disturbance, reducing water usage, and lowering pollution levels. This not only helps in securing mining licenses and approvals but also in maintaining a positive public image and good relations with local communities.

Introducing Tianhe: A Leader in Geotechnical Drilling

Tianhe is committed to providing cutting-edge solutions for drill placement to enhance ore extraction performance. With a focus on technological innovation and environmental responsibility, Tianhe stands out as a reliable partner for optimizing drilling operations.

Tianhe's expertise in drill placement is particularly crucial when dealing with cramped ore patches. By utilizing advanced technology and precision engineering, Tianhe can strategically position drills to access hard-to-reach ore deposits efficiently. This not only maximizes extraction performance but also minimizes environmental impact by reducing the need for extensive excavation.

Cramped Ore Patches and Drill Placement

Challenges of Drilling in Tight Spaces

Mining drills face numerous challenges when operating in cramped ore patches. Limited space makes it difficult to maneuver the drilling rig, leading to potential damage to equipment and safety hazards for workers. Additionally, accessing these tight spaces can be a logistical nightmare, requiring careful planning and precision.

Maximizing Efficiency in Cramped Areas

To maximize efficiency in cramped areas, mining companies must invest in advanced drill rigs specifically designed for tight spaces. These rigs are equipped with enhanced maneuverability and compact size to navigate through narrow passages and confined work areas. By utilizing these specialized tools, companies can ensure that they extract the maximum amount of ore from these challenging locations.

Tianhe's Innovative Solutions for Cramped Ore Patches

Tianhe has developed cutting-edge rock drills and rotary drills that are specifically tailored for cramped ore patches. Their innovative designs prioritize mobility and precision, allowing miners to access hard-to-reach areas while maintaining safety and productivity. With Tianhe's expertise, mining companies can overcome the challenges of drilling in tight spaces and optimize their ore extraction operations.

Tianhe's innovative solutions for cramped ore patches have revolutionized the mining industry by addressing the challenges of drilling in tight spaces. With their cutting-edge rock drills and rotary drills, miners can now access hard-to-reach areas with ease, ensuring maximum productivity and safety. The mobility and precision of Tianhe's designs allow for efficient drill placement in spaced ore patches, enabling mining companies to optimize their ore extraction operations even in the most challenging environments.

Spaced Ore Patches and Drill Placement

Advantages of Spacing Out Drilling Locations

Spacing out drilling locations, especially in the context of mining, oil, and gas extraction, involves strategically positioning the sites where drilling operations are conducted. This approach can offer several advantages, contributing to the efficiency, environmental sustainability, and overall success of the extraction projects. Here are some key benefits:

- Enhanced Resource Recovery: Properly spaced drilling locations can lead to more efficient resource recovery. In oil and gas extraction, for example, it allows for the more effective drainage of resources from the reservoir. In mining, strategic drilling can help in accurately defining the ore body, leading to optimized extraction methods that improve yield.

- Reduced Environmental Impact: By minimizing the number of drilling sites, the environmental footprint of extraction activities can be significantly reduced. Less land is disturbed, which means there is less deforestation, habitat destruction, and overall landscape alteration. This approach also minimizes the amount of waste generated and reduces water usage and pollution.

- Cost Efficiency: Spacing out drilling locations can lead to substantial cost savings. Fewer drilling sites mean less capital is required for drilling equipment, infrastructure (such as roads and pipelines), and maintenance. It also reduces the operational costs associated with moving machinery and personnel between sites, as well as the costs of environmental restoration.

- Improved Safety: Concentrating operations in fewer, well-planned locations can enhance safety for workers. It simplifies logistics and emergency response, reduces the risk of accidents related to transportation between sites, and allows for more focused and thorough implementation of safety protocols.

- Better Data Acquisition and Analysis: With strategic drilling, the data collected from each location can be more representative and useful for modeling and analysis. This can lead to a better understanding of the geological structure, resource distribution, and potential environmental impacts, facilitating more informed decision-making and planning.

- Community Relations and Land Use: Spacing out drilling sites can also mitigate the impact on local communities and land use. It reduces the area over which communities are affected by noise, traffic, and visual impacts. Moreover, it allows for the coexistence of extraction activities with other land uses, such as agriculture or conservation, by minimizing the spatial overlap.

- Regulatory Compliance and Permitting: Fewer drilling locations can simplify the process of obtaining necessary environmental and operational permits. Regulatory bodies often require comprehensive assessments of the environmental and social impacts of drilling activities. By reducing the number of sites, companies can more effectively address these concerns, potentially speeding up the permitting process.

Ensuring Uniform Extraction in Spaced Areas

Uniform extraction is crucial in spaced ore patches to maximize resource utilization and avoid leaving behind valuable minerals. Tianhe's advanced rock drills are designed to ensure consistent extraction across spaced areas by providing precise control over drilling depth and angle. This expertise guarantees that no part of the ore patch is overlooked, leading to a more thorough extraction process.

Tianhe's advanced rock drills are also equipped with state-of-the-art sensors and monitoring systems that provide real-time data on the drilling process. This allows for immediate adjustments to be made in drilling depth and angle, ensuring that extraction remains uniform even in the face of varying geological conditions. By utilizing cutting-edge technology, Tianhe sets itself apart as a leader in optimizing drilling processes for spaced ore patches.

Tianhe's Expertise in Optimizing Drilling in Spaced Patches

Tianhe has established itself as a leader in optimizing drill placement in spaced ore patches through its innovative approach to geotechnical drilling. With a focus on precision and efficiency, Tianhe's drill rigs are equipped with cutting-edge technology that allows for accurate positioning and uniform extraction across spaced areas. This expertise ensures that mining operations can extract the maximum amount of resources from each patch while minimizing waste.

By leveraging Tianhe's expertise in optimizing drill placement for both cramped and spaced ore patches, mining companies can achieve significant improvements in their operational efficiency and resource utilization. As the industry continues to evolve, strategic drill placement will play an increasingly important role in maximizing ore quality and quantity while minimizing environmental impact.

Partnering with Tianhe means gaining access to state-of-the-art drilling technology that can revolutionize your mining operations. With a commitment to excellence and environmental responsibility, Tianhe is poised to lead the way in enhancing drilling performance for years to come.

Proper drill placement is essential for achieving optimal results in ore extraction. By understanding the advantages of spacing out drilling locations and leveraging Tianhe's expertise, mining companies can ensure uniform extraction across all types of ore patches while minimizing environmental impact.

Impact on Ore Quality and Quantity

Mining drills play a crucial role in determining the quality and quantity of extracted ore. Proper drilling placement is essential in ensuring that ore is extracted efficiently and without contamination, ultimately impacting the overall quality of the ore.

Significance of Proper Drilling Placement on Ore Quality

The precise placement of mining drills is vital in maintaining the integrity of the surrounding rock formations and minimizing any potential contamination during extraction. Tianhe understands the importance of this, which is why their drilling rigs are designed to be highly accurate and efficient, ensuring minimal disturbance to the surrounding environment.

Maximizing Ore Quantity through Strategic Drill Placement

Strategic drill placement can significantly impact the quantity of ore that can be extracted from a particular site. By strategically positioning drill rigs, miners can access a larger area of high-quality ore deposits, ultimately maximizing the quantity of ore that can be extracted. Tianhe's innovative drilling solutions are designed to optimize this process, allowing for maximum ore extraction.

Tianhe's Role in Enhancing Ore Quality and Quantity

Tianhe plays a crucial role in enhancing both the quality and quantity of extracted ore through their advanced drilling technology. Their state-of-the-art mining drills and drill rigs are engineered to ensure precision in placement, resulting in higher-quality ore extraction with minimal waste. With Tianhe as a partner, mining operations can achieve enhanced performance in both ore quality and quantity.

By utilizing Tianhe's expertise in geotechnical drilling, mining operations can achieve optimal results in both the quality and quantity of extracted ore. Their innovative solutions for strategic drill placement enable miners to enhance their performance while minimizing environmental impact. As a leader in geotechnical drilling, Tianhe continues to revolutionize the industry with cutting-edge technological solutions for efficient drill placement.

Environmental Considerations

In the mining industry, the impact on the environment is a critical concern. Tianhe understands the importance of mitigating environmental impact through optimal drill placement. By strategically positioning mining drills, we can minimize disturbance to natural habitats and reduce soil erosion, ensuring that our operations are as environmentally friendly as possible.

Mitigating Environmental Impact through Optimal Drill Placement

Tianhe's advanced drilling rigs are designed to minimize environmental disruption by precisely targeting ore deposits without unnecessary disturbance to surrounding areas. By carefully planning and executing drill placement, we can significantly reduce the impact on local ecosystems and wildlife habitats. This commitment to responsible drilling practices sets Tianhe apart as a leader in environmentally conscious mining operations.

Sustainable Mining Practices with Proper Drill Placement

Sustainability is at the core of Tianhe's approach to mining. Through proper drill placement, we aim to maximize resource extraction while minimizing environmental harm. By adhering to sustainable practices and utilizing innovative technologies, we ensure that our mining operations have a minimal ecological footprint and contribute to long-term environmental preservation.

Tianhe's Commitment to Environmental Responsibility

Tianhe is dedicated to upholding the highest standards of environmental responsibility in all aspects of our operations. From research and design to production and management, we prioritize sustainable practices that prioritize ecological preservation while meeting our clients' needs for efficient ore extraction.

With Tianhe's expertise in geotechnical drilling and unwavering commitment to environmental responsibility, mining companies can confidently partner with us for enhanced drilling performance while prioritizing sustainability for future generations.

Technological Innovations in Drill Placement

Advancements in Drill Rig Technology for Efficient Placement

In the ever-evolving world of mining, drill rig technology has seen significant advancements to improve efficiency and precision in ore extraction. Tianhe, a leader in geotechnical drilling, has been at the forefront of developing state-of-the-art drilling rigs that are capable of navigating even the most challenging terrain with ease. These innovative rigs are designed to maximize productivity while minimizing operational costs, making them a game-changer in the industry.

With the integration of automation technology, drill placement has become more precise than ever before. Tianhe's advanced drilling rigs are equipped with automated systems that can accurately position the drills to ensure optimal extraction of ore. This level of precision not only increases the efficiency of the mining operation but also reduces the risk of errors and potential safety hazards associated with manual drill placement. By harnessing the power of automation, Tianhe has set a new standard for precision in drill placement within the mining industry.

Utilizing Automation for Precision in Drill Placement

Automation has revolutionized the way mining drills are placed, allowing for unparalleled precision and accuracy. Tianhe's cutting-edge automation technology ensures that drill rigs are strategically positioned to extract ore with optimal efficiency. This not only streamlines the extraction process but also reduces human error, resulting in higher-quality ore extraction and increased productivity.

With Tianhe's state-of-the-art automation technology, mining companies can now rely on precise and accurate drill placement to maximize their ore extraction potential. This advanced system not only streamlines the entire process but also minimizes the margin of error, ensuring that the extracted ore is of the highest quality. As a result, mining operations can experience increased productivity and profitability, setting a new standard for efficiency in the industry.

Tianhe's Cutting-Edge Technological Solutions for Drill Placement

Tianhe's commitment to technological innovation is evident in its range of advanced drilling rigs that cater to various mining requirements. From rock drills to rotary drills, their equipment is designed to meet the specific needs of different mining operations. With a focus on reliability and performance, Tianhe's drilling rigs are equipped with the latest technological solutions to ensure seamless placement and extraction of ore.

By leveraging these technological innovations, mining companies can significantly enhance their drilling performance while minimizing environmental impact and maximizing ore quantity and quality. With Tianhe's expertise and cutting-edge solutions, the future of drill placement looks promising as it continues to pave the way for sustainable and efficient mining practices.

Partner with Tianhe for Enhanced Drilling Performance

Mining drills play a crucial role in efficient ore extraction, and strategic drill placement is key to achieving optimal results. Tianhe's expertise in geotechnical drilling and innovative solutions make them the ideal partner for enhancing drilling performance.

Achieving Optimal Results through Strategic Drill Placement

With the right placement of mining drills, companies can maximize ore extraction efficiency and ensure uniform extraction in both cramped and spaced patches. Tianhe's cutting-edge technological solutions for drill placement are designed to address these challenges and optimize drilling performance.

The Future of Mining Drills and Ore Extraction

As technology continues to advance, the future of mining drills and ore extraction looks promising. Advancements in drill rig technology, such as automation for precision in drill placement, will further enhance efficiency and productivity in the mining industry.

Tianhe's commitment to environmental responsibility, sustainable mining practices, and their role in enhancing ore quality and quantity make them the ideal partner for companies looking to optimize their drilling performance. With its expertise in research, design, production, sales, and management of geotechnical drilling equipment, Tianhe is well-positioned to support companies in achieving their goals.

Partnering with Tianhe means gaining access to innovative solutions that can revolutionize your approach to geotechnical drilling. Don't miss out on the opportunity to enhance your drilling performance with Tianhe's expertise!