Introduction

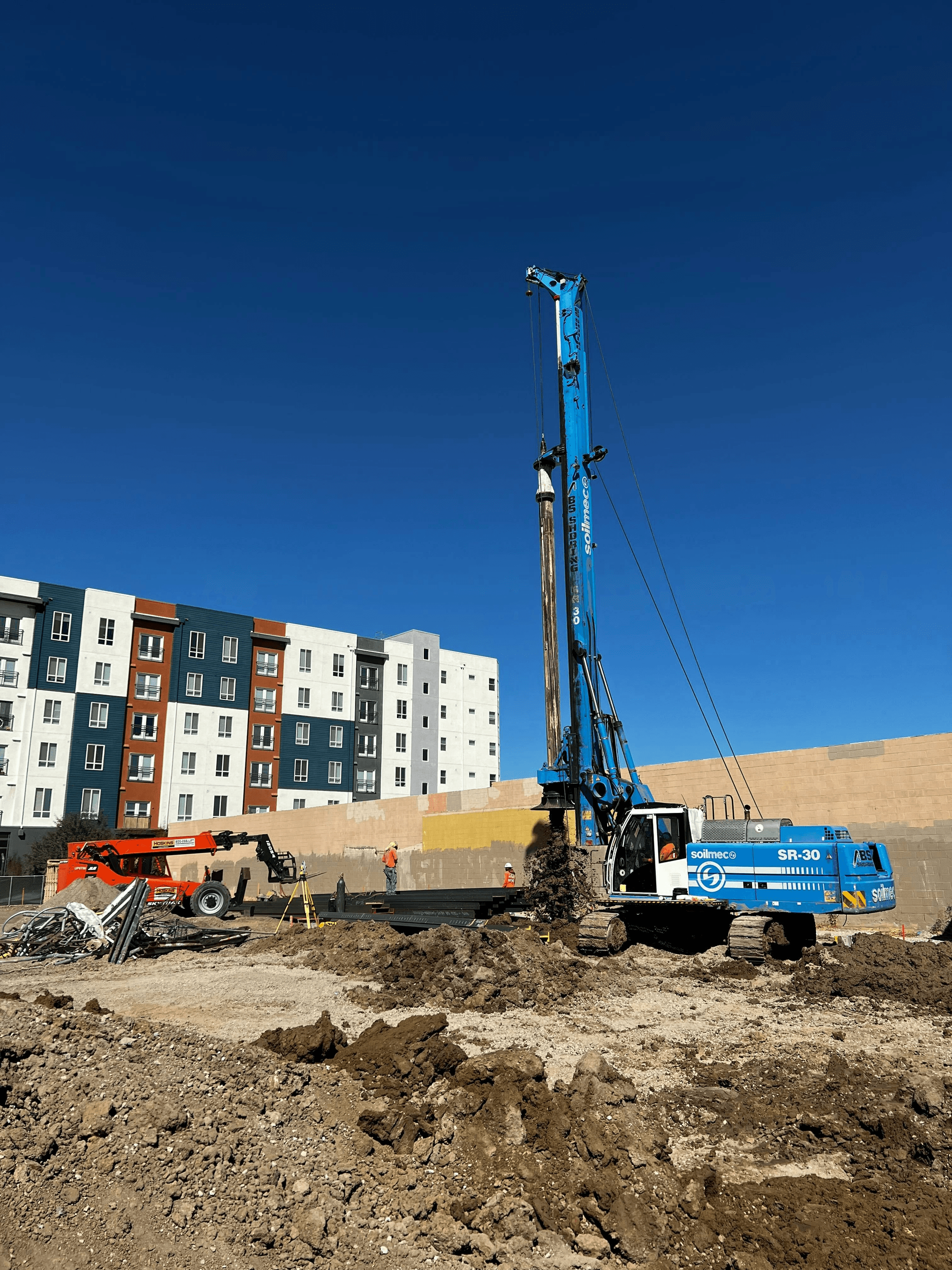

Crawler drilling rigs are powerful machines that have revolutionized the construction and mining industries. These versatile machines are capable of reaching remote and challenging locations, making them an essential tool for various projects. One of the most innovative developments in this field is the crawler pneumatic drilling rig, which has unleashed a new level of potential in well construction.

Understanding the Power of Crawler Drilling Rigs

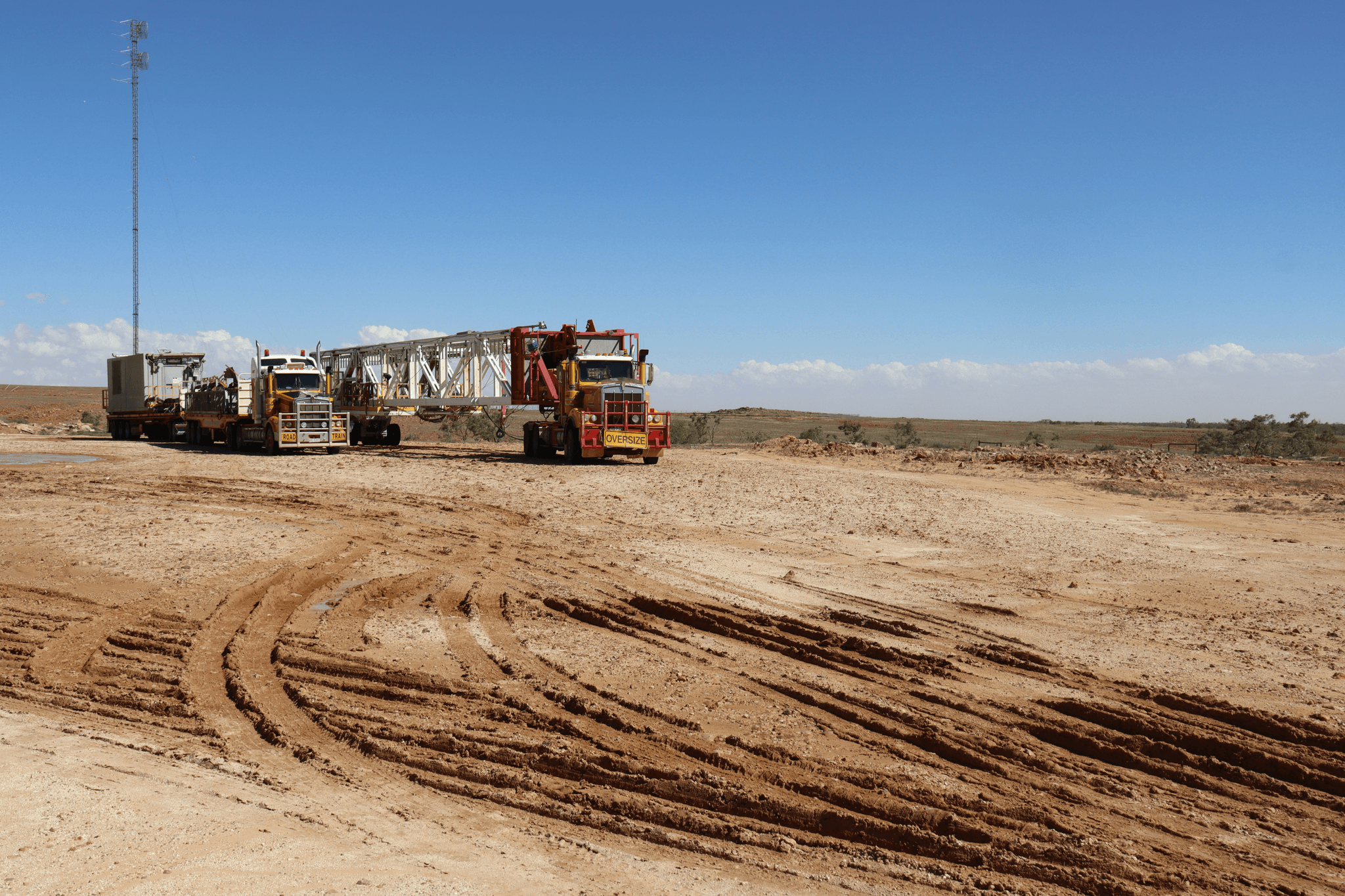

The power of crawler drilling rigs lies in their ability to navigate through rough terrains with ease, providing access to areas that traditional drilling machines cannot reach. Their robust design and advanced technology make them indispensable for a wide range of applications, from geotechnical exploration to foundation construction.

Exploring the Versatility of Crawler Drilling Machines

Crawler drilling machines are incredibly versatile, capable of performing various tasks such as soil sampling, rock coring, and water well drilling. Their adaptability makes them ideal for different industries, including mining, oil and gas exploration, and environmental engineering.

Unleashing the Potential of A Crawler Pneumatic Crawler Drilling Rig

The introduction of the crawler pneumatic drilling rig has elevated the capabilities of well construction to new heights. This innovative machine utilizes pneumatic power to deliver efficient and precise drilling operations, significantly impacting productivity and cost-effectiveness in the industry.

What is a Crawler Drilling Rig?

A crawler drilling rig is a powerful and versatile machine used for drilling in various industries such as construction, mining, and oil exploration. It is designed to navigate through rough terrains and deliver precise drilling operations in challenging environments.

Explaining the Functionality and Purpose

The functionality of a crawler drilling rig lies in its ability to move on tracks or crawlers, providing stability and mobility on uneven surfaces. Its purpose is to drill holes for various applications such as foundation piling, mineral exploration, geotechnical testing, and water well construction.

Examining the Key Components and Systems

Key components of a crawler drilling rig include the mast, rotary head, drill pipe, hydraulic system, control panel, and power source. These systems work together to provide efficient drilling operations with precision and control.

Highlighting the Applications and Industries

Crawler drilling rigs are widely used in industries such as construction for building foundations, mining for mineral exploration, geotechnical testing for soil analysis, water well construction for access to clean water sources, and oil exploration for extraction of natural resources.

The Three Main Types of Drilling Rigs

A crawler drilling rig is a versatile machine that comes in three main types: rotary drilling rigs, percussion drilling rigs, and auger drilling rigs. Each type has its own distinctions and capabilities that make them suitable for different applications and industries.

Rotary drilling rigs are known for their ability to create deep, large-diameter boreholes in various types of soil and rock formations. They are highly efficient and can handle tough terrains, making them ideal for oil and gas exploration, mining, and construction projects.

On the other hand, percussion drilling rigs use a hammering action to break through hard rock formations. While they may not be as efficient as rotary drilling rigs in softer soils, they excel in hard rock mining, quarrying, and tunneling applications where precision is crucial.

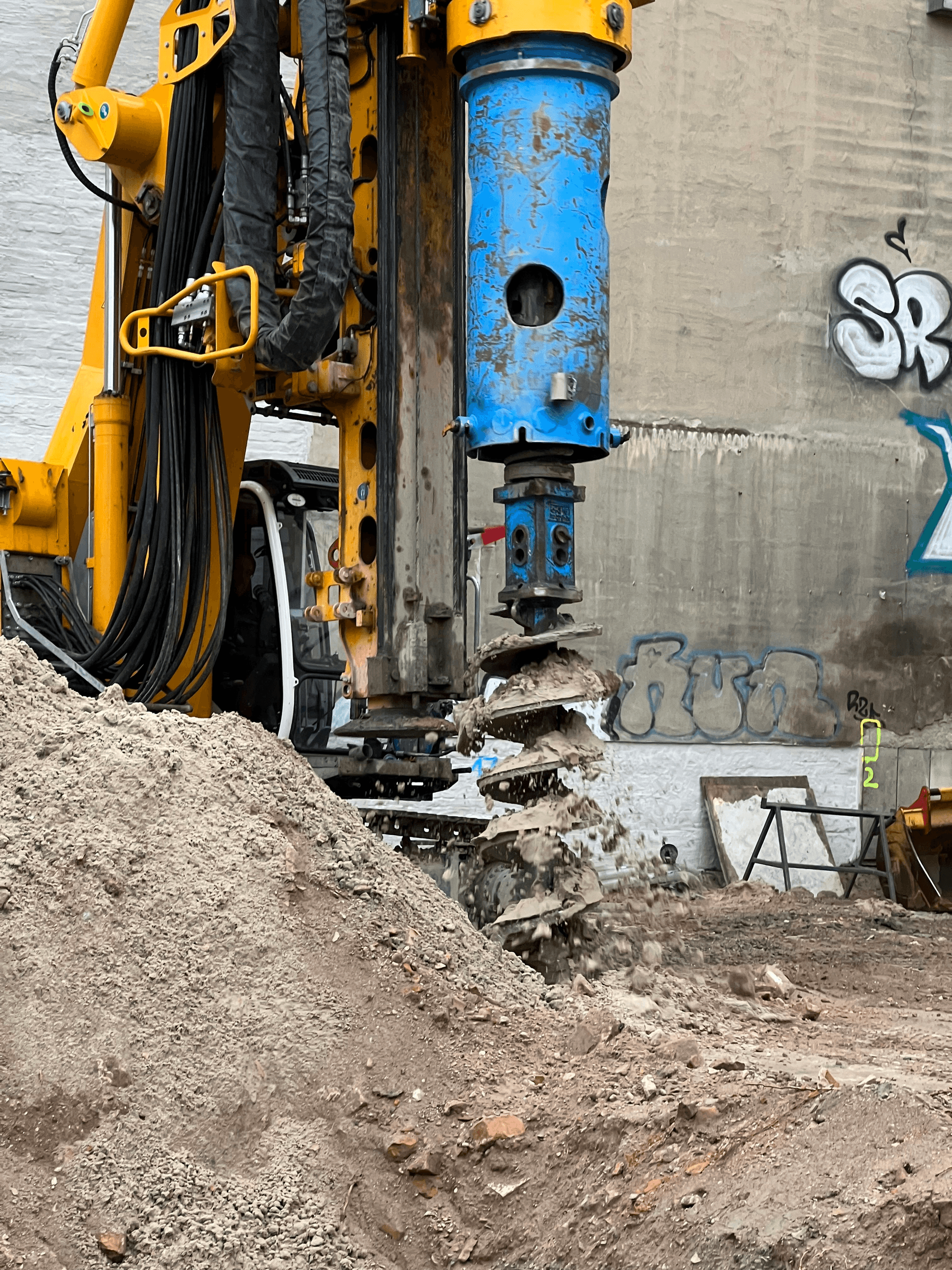

Auger drilling rigs are specialized machines designed for creating shallow boreholes using a helical screw blade. They are commonly used for environmental sampling, geotechnical investigations, and foundation construction due to their ability to extract soil samples with minimal disturbance.

Crawler drilling machines offer distinct advantages and disadvantages depending on the type of rig being used. While rotary drilling rigs are highly efficient and versatile, they require more complex maintenance compared to percussion or auger drilling rigs.

Real-world applications of these three main types of crawler drilling rigs can be seen in major infrastructure projects such as bridge construction, road building, dam foundations, and offshore oil exploration. Their versatility makes them indispensable tools across various industries worldwide.

The Four Systems of a Drilling Rig

When it comes to the functionality of a crawler drilling rig, it's essential to understand the interplay and integration of its four main systems. These systems include the power, hoisting, rotation, and circulation systems. Each system plays a crucial role in ensuring the efficiency and productivity of the drilling process.

Understanding the Interplay and Integration

The power system provides the necessary energy to drive all other systems, while the hoisting system is responsible for lifting and lowering the drill string and casing. The rotation system enables the drill bit to penetrate the surface by spinning it, and finally, the circulation system ensures that drilling fluid is circulated to cool down the drill bit and carry cuttings out of the borehole.

The interplay and integration of these systems are crucial for maximizing efficiency and productivity in drilling operations. The power system not only drives all other systems but also plays a vital role in ensuring smooth and uninterrupted drilling processes. Similarly, the hoisting system's ability to lift and lower the drill string and casing with precision is essential for maintaining operational continuity. Furthermore, the rotation system's seamless spinning of the drill bit is imperative for achieving accurate penetration, while the circulation system's efficient cooling of the drill bit and removal of cuttings contribute to overall productivity.

Maximizing Efficiency and Productivity

By understanding how these systems work together, operators can maximize efficiency and productivity during drilling operations. Proper coordination between these systems is essential for smooth drilling processes, minimizing downtime, and achieving optimal results in well construction projects.

Realizing Impact on Well Construction

The seamless integration of these four systems significantly impacts well construction by ensuring precise drilling operations without compromising safety or environmental standards. This holistic approach to crawler drilling rig operation sets a strong foundation for successful well construction projects.

The auger drilling rig is a specialized piece of equipment used in well construction projects. This type of rig is designed to efficiently drill into the earth using a rotating helical screw blade, known as an auger, to create boreholes for various applications such as water wells, soil sampling, and environmental testing. The use of an auger drilling rig offers precise control over the drilling process, allowing for accurate placement of well casings and ensuring the integrity of the well structure. Additionally, this type of rig is known for its versatility and ability to operate in a wide range of soil and rock conditions, making it a valuable asset in well construction projects.

What is Auger Drilling Rig?

An auger drilling rig is a specialized type of crawler drilling machine designed for drilling holes into the ground using a helical screw blade called an auger. This innovative rig is known for its ability to efficiently penetrate various types of soil and rock formations, making it ideal for geotechnical and environmental applications.

Unraveling the Innovation and Specialization

The innovation of the auger drilling rig lies in its unique helical design, which allows for effective soil removal and sample collection during the drilling process. This specialization makes it a preferred choice for environmental assessments, soil sampling, and geotechnical investigations in construction and infrastructure projects. The auger rig's ability to extract continuous soil samples without disturbing the surrounding area showcases its efficiency and precision.

Showcasing the Unique Advantages and Use Cases

One of the key advantages of the auger drilling rig is its versatility in handling different types of soil conditions, including cohesive soils, granular soils, and even fractured rock formations. Its ability to perform continuous sampling while minimizing site disturbance makes it an invaluable tool for environmental impact studies, groundwater monitoring well installations, and soil remediation projects.

Exploring the Future Potential and Developments

As technology continues to advance, auger drilling rigs are expected to see further developments in automation, data integration, and real-time monitoring capabilities. These advancements will enhance their efficiency in collecting accurate subsurface information while reducing operational costs and environmental impact. With ongoing research and development efforts, we can anticipate even more sophisticated auger drilling rigs that will revolutionize environmental exploration and site characterization processes.

A Crawler Pneumatic Crawler Drilling Rig: A Game-changer in Well Construction

Highlighting the Innovations and Technological Advancements

The crawler pneumatic drilling rig represents a significant leap forward in well construction technology, with its innovative pneumatic system that provides powerful and efficient drilling capabilities. This cutting-edge rig is equipped with advanced sensors and control systems, allowing for precise and automated operation, enhancing safety and accuracy on the job site.

The pneumatic drilling rig also boasts a compact and maneuverable design, allowing it to access and operate in tight or challenging work environments with ease. This versatility not only increases efficiency but also reduces the need for additional equipment or resources, ultimately saving time and costs for well construction projects. Additionally, the rig's innovative design minimizes environmental impact by reducing the footprint required for drilling operations, aligning with sustainable and responsible practices in the industry.

Showcasing the Efficiency and Cost-effectiveness

One of the key advantages of a crawler pneumatic drilling rig is its exceptional efficiency and cost-effectiveness. The rig's ability to operate in various terrains, including rough and uneven surfaces, significantly reduces the need for additional groundwork or preparation. This not only saves time but also minimizes operational costs, making it an ideal choice for projects with budget constraints.

Furthermore, the crawler pneumatic drilling rig's ability to navigate through challenging terrain also reduces the need for manual labor and heavy machinery, leading to a safer work environment. This not only cuts down on potential accidents and injuries but also lowers insurance and liability costs for the project. Additionally, the rig's efficient operation means that projects can be completed in a shorter timeframe, allowing for quicker turnaround times and faster realization of returns on investment.

Real-world Examples and Success Stories

In real-world applications, the crawler pneumatic drilling rig has proven to be a game-changer in well construction projects across different industries. From geotechnical investigations to environmental monitoring, this versatile rig has consistently delivered exceptional results, earning praise for its reliability, speed, and precision. Its adaptability to diverse drilling requirements has made it a go-to solution for companies looking to streamline their operations without compromising on quality.

Furthermore, the crawler pneumatic drilling rig has demonstrated its effectiveness in remote and challenging terrains, where traditional drilling methods may not be feasible. Its ability to navigate rugged landscapes and deliver precise drilling results has made it an invaluable asset for projects in difficult-to-access locations. This versatility has allowed companies to expand their exploration and construction efforts into areas previously considered off-limits, opening up new opportunities for growth and development.

Stay tuned for more insights into the world of modern drilling technology with TEAMWHOLE!

Conclusion

Modern crawler drilling rigs are revolutionizing the well construction industry, offering versatility, efficiency, and cost-effectiveness. With the power of crawler drilling machines, industries can build a strong foundation with efficient well construction, embracing the future of drilling technology with TEAMWHOLE at the forefront.

Harnessing the Power of Modern Crawler Drilling Rigs

The innovation and technological advancements in crawler drilling rigs have unlocked new possibilities in well construction. The versatility and efficiency of these machines are game-changers, offering a wide range of applications across various industries. With their power and precision, modern crawler drilling rigs are reshaping the future of well construction.

The increased power and precision of modern crawler drilling rigs have revolutionized the way well construction is approached. These machines are capable of handling a wide range of drilling tasks with ease, making them indispensable in industries such as oil and gas, construction, and mining. Their versatility allows for efficient drilling in various terrains and conditions, providing a strong foundation for infrastructure development.

Building a Strong Foundation with Efficient Well Construction

Efficient well construction is crucial for sustainable development and growth in various industries. Crawler drilling rigs play a pivotal role in building a strong foundation by maximizing productivity and minimizing operational costs. Their adaptability and reliability make them essential tools for achieving efficient well construction.

Embracing the Future of Drilling Technology with TEAMWHOLE

As industries look towards the future, embracing cutting-edge drilling technology is essential for staying ahead of the curve. With TEAMWHOLE's innovative solutions and expertise in crawler drilling rigs, businesses can confidently navigate the evolving landscape of well construction. By leveraging advanced technology and industry-leading practices, TEAMWHOLE is driving the future of drilling technology forward.

In addition to their focus on innovation, TEAMWHOLE is committed to providing exceptional customer service and support. Their team of experts is dedicated to working closely with businesses to understand their unique needs and challenges, ensuring that they receive tailored solutions that maximize efficiency and productivity. With a customer-centric approach, TEAMWHOLE goes above and beyond to build long-lasting partnerships and deliver results that exceed expectations.