Introduction

When it comes to mining operations, having the right tools is crucial for success. One such tool that has revolutionized the industry is the air hammer drill. These powerful machines have transformed the way mining is done, offering efficiency and precision like never before. Whether you're looking for a rotary hammer drill or a traditional hammer and drill combo, there are several top options available in the market to suit your specific mining needs.

Top DTH Air Hammer Drill Options for Mining

Tianhe, Sandvik, and Atlas Copco are just a few of the leading brands offering top-notch air hammer drills for mining operations. With advanced features and cutting-edge technology, these drills are designed to handle even the toughest drilling tasks in the most demanding mining environments.

When considering which air hammer drill is the best fit for your mining needs, it's important to take into account factors such as drilling depth, speed, and efficiency. Tianhe, Sandvik, and Atlas Copco all offer a range of options to suit different requirements, from smaller-scale operations to large-scale mining projects. By carefully evaluating the specific demands of your mining operation, you can select the most suitable air hammer drill that will maximize productivity and minimize downtime.

Choosing the Right Hammer Drill for Your Mining Needs

Selecting the right hammer drill for your mining project is crucial to ensure efficiency and safety. Factors such as drilling depth, rock hardness, and environmental conditions must be taken into consideration when choosing a suitable rotary hammer or air hammer for your specific needs.

When considering the drilling depth for your mining project, it's important to choose a hammer drill that can reach the required depth without sacrificing efficiency. A rotary hammer with a powerful motor and high impact energy may be necessary for deeper drilling, while an air hammer with a high air pressure capacity can also be effective. Understanding the depth of the drilling required will help you select the right tool for the job and ensure that your mining operations run smoothly.

The Best DTH Air Hammer Drills for Efficient Mining Operations

The best DTH air hammer drills on the market offer unmatched performance and reliability, making them essential tools for efficient mining operations. From powerful DTH hammers to precision-engineered drill bits, these drills are designed to maximize productivity while minimizing downtime.

The best DTH air hammer drills on the market offer unmatched performance and reliability, making them essential tools for efficient mining operations. From powerful DTH hammers to precision-engineered drill bits, these drills are designed to maximize productivity while minimizing downtime. With their durable construction and advanced technology, these drills can withstand the tough conditions of mining environments, ensuring consistent and reliable performance day in and day out.

Understanding DTH Air Hammer Drills

DTH air hammer drills, also known as down-the-hole drills, work by using a pneumatic reciprocating piston to create high-impact force, driving the drill bit into the rock. This method allows for faster and more efficient drilling in hard rock formations, making it ideal for mining operations.

How DTH Air Hammer Drills Work

The air hammer drill uses compressed air to power the piston inside the drill, which strikes the back of the drill bit, creating a powerful impact that fractures the rock. This process continues as the drill is rotated and advanced, allowing for rapid penetration into the ground. The result is precise and efficient drilling in even the toughest geological formations.

In addition to its precision and efficiency, DTH air hammer drills offer the benefit of minimal vibration during operation. This reduces operator fatigue and ensures a smoother drilling process, ultimately leading to higher productivity. Furthermore, the use of compressed air as a power source makes these drills more environmentally friendly compared to traditional drilling methods that rely on fossil fuels.

Benefits of Using DTH Air Hammer Drills

The use of DTH air hammer drills offers several advantages for mining operations. These include faster drilling speeds, increased accuracy and precision in hole placement, reduced wear on equipment due to minimal vibration, and improved safety for operators working with heavy machinery.

In addition to the benefits mentioned, high-quality DTH air hammer drills also offer greater versatility in drilling through various types of rock formations. This means that mining operations can tackle a wider range of geological challenges with the same equipment, saving time and resources. Furthermore, these drills are designed to minimize downtime, with efficient maintenance and easy repair features that keep them operating at peak performance for longer periods. This reliability is essential for meeting production targets and maximizing the return on investment in mining operations.

Features to Look for in a High-Quality DTH Air Hammer Drill

When choosing a high-quality DTH air hammer drill, look for features such as durable construction materials that can withstand harsh mining environments, efficient energy consumption to minimize operational costs, and compatibility with various types of drill bits for versatility in different geological conditions.

In addition to the aforementioned features, it is important to consider the impact power and drilling speed of the DTH air hammer drill. Look for a drill that offers high impact power to effectively break through hard rock formations, as well as adjustable drilling speeds to accommodate different types of materials. This will ensure efficient and precise drilling operations, ultimately saving time and resources in mining projects.

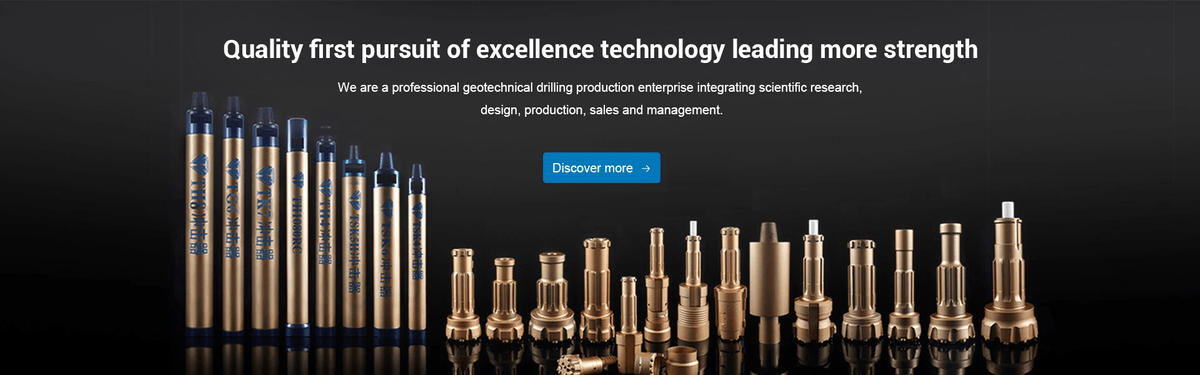

Top Brands in the Industry

When it comes to top-notch geotechnical drilling equipment, Tianhe is a name that stands out. With a solid reputation for producing high-quality air hammer drills, Tianhe has become a leader in the industry, providing reliable and efficient solutions for mining operations around the world.

Tianhe: A Leader in Geotechnical Drilling Equipment

Tianhe has established itself as a go-to brand for air hammer drills, offering a wide range of options designed to meet the specific needs of mining projects. Known for their durability and performance, Tianhe's air hammer drills are trusted by professionals in the field for their ability to deliver consistent results even in challenging drilling conditions.

Popular DTH Air Hammer Drill Brands in the Market

In addition to Tianhe, there are several other popular brands in the market that offer high-quality DTH air hammer drills. Companies like Sandvik, Atlas Copco, and Boart Longyear are known for their reliable and innovative drilling equipment, providing a variety of options to suit different mining requirements.

Key Features of Leading DTH Air Hammer Drills

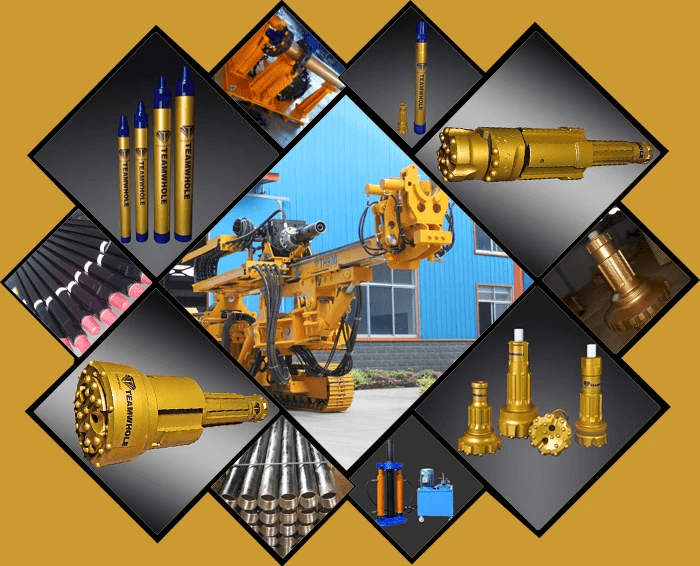

Leading DTH air hammer drills come with key features that set them apart from others in the market. These features include advanced rotary hammer technology, precision-engineered drill bits, and ergonomic designs for enhanced operator comfort and safety. With powerful performance and efficient operation, these drills are essential tools for maximizing productivity in mining operations.

Types of Drill Bits

When it comes to DTH drilling, the button bit is a crucial component that plays a major role in the success of your mining operations. These specialized drill bits are designed to withstand the high impact and pressure of DTH hammer drills, ensuring efficient and precise drilling in challenging geological conditions. With their durable carbide buttons, button bits are essential for achieving optimal penetration rates and maintaining consistent performance in air hammer drilling.

Button Bit: A Crucial Component in DTH Drilling

Button bits are specifically engineered to deliver maximum energy transfer from the DTH hammer to the rock formation, resulting in faster drilling speeds and reduced wear on both the bit and the hammer. Their unique design allows for efficient removal of cuttings, minimizing downtime and maximizing productivity during mining operations. With various configurations available to suit different rock types, button bits are essential for achieving superior drilling performance with your air hammer drill.

DTH Hammer: Powering Your Mining Operations

The DTH hammer is a powerful tool that drives the rotation of the drill bit while simultaneously delivering high-impact blows to break through rock formations during mining operations. This rotary hammer drill uses compressed air to create a rapid succession of blows that pulverize hard materials, making it an essential component for powering your air hammer drill in challenging geological conditions. With its robust construction and precision engineering, the DTH hammer ensures efficient energy transfer for optimal drilling performance.

DTH Drill Bit: Ensuring Precision and Accuracy in Drilling

The DTH drill bit is a vital element in ensuring precision and accuracy during drilling operations with an air hammer drill. Designed to withstand extreme forces while maintaining sharpness and durability, these specialized bits are essential for achieving consistent hole quality and minimizing deviation from target depths. With advanced features such as carbide inserts and optimized cutting structures, DTH drill bits offer superior performance for achieving precise results in demanding mining applications.

Best Practices for Using DTH Air Hammer Drills

When using an air hammer drill, it's crucial to start by selecting the right drill bit for the job. Ensure that the bit is compatible with your specific drilling needs and the type of rock or material you'll be drilling into. Additionally, always inspect the drill and its components before each use to identify any signs of wear and tear.

Tips for Maximizing the Performance of Your Hammer Drill

To maximize the performance of your air hammer drill, it's essential to maintain a consistent feed force while drilling. This will help prevent unnecessary wear on the drill bit and ensure a smooth and efficient drilling process. Furthermore, adjusting the air pressure based on the hardness of the material being drilled can also enhance performance and extend the lifespan of your equipment.

Maintenance and Safety Guidelines for DTH Air Hammer Drills

Proper maintenance is key to ensuring the longevity and safety of your air hammer drill. Regularly lubricate moving parts, inspect seals for any signs of damage, and clean out dust or debris that may accumulate during use. Additionally, always follow safety guidelines such as wearing appropriate personal protective equipment (PPE) and adhering to proper operating procedures to minimize risks associated with drilling operations.

Common Mistakes to Avoid When Using DTH Air Hammer Drills

One common mistake when using air hammer drills is neglecting to monitor drilling parameters such as rotation speed and feed pressure. It's important to constantly monitor these factors to prevent overheating or premature wear on components. Another common error is failing to properly secure workpieces before drilling, which can lead to instability and potential accidents.

Applications and Case Studies

DTH Air Hammer Drills in Mining Exploration

When it comes to mining exploration, the use of DTH air hammer drills is essential for reaching deep into the earth's surface. These powerful tools are capable of drilling through even the toughest rock formations, making them invaluable for uncovering valuable mineral deposits. Whether it's for prospecting or identifying potential mining sites, a reliable air hammer drill is a must-have for any exploration project.

Success Stories of Implementing DTH Air Hammer Drills

Mining companies around the world have experienced tremendous success after implementing DTH air hammer drills in their operations. By using these advanced tools, they've been able to significantly increase their drilling efficiency and accuracy, leading to higher productivity and profitability. From small-scale mining operations to large-scale projects, the impact of using a high-quality air hammer drill cannot be overstated.

Innovative Uses of DTH Air Hammer Drills in the Mining Industry

Innovative mining companies are finding new and creative ways to leverage the power of DTH air hammer drills in their operations. From using them for tunneling and excavation to precision blasting and rock fragmentation, these versatile tools are revolutionizing how mining tasks are carried out. The adaptability and reliability of air hammer drills make them indispensable for driving innovation in the mining industry.

Conclusion

When it comes to choosing the right DTH air hammer drill for your mining project, it's essential to consider factors such as drilling depth, rock hardness, and overall project requirements. By selecting a high-quality air hammer drill that meets these needs, you can ensure efficient and successful drilling operations.

Choosing the Right DTH Air Hammer Drill for Your Mining Project

With a wide range of options available in the market, it's crucial to thoroughly evaluate the features and capabilities of each air hammer drill before making a decision. Consider factors such as impact energy, drilling speed, and durability to find the best fit for your specific mining project.

Maximizing Efficiency with the Best DTH Air Hammer Drills

Investing in top-quality DTH air hammer drills can significantly enhance the efficiency of your mining operations. These advanced tools offer superior drilling performance, increased productivity, and reduced downtime, ultimately leading to cost savings and improved overall results.

Advancing Your Mining Operations with DTH Air Hammer Drills

By incorporating innovative DTH air hammer drills into your mining operations, you can take advantage of cutting-edge technology to achieve greater precision, accuracy, and safety in drilling processes. These powerful tools are designed to handle even the toughest rock formations with ease, allowing you to advance your mining projects with confidence.