Introduction

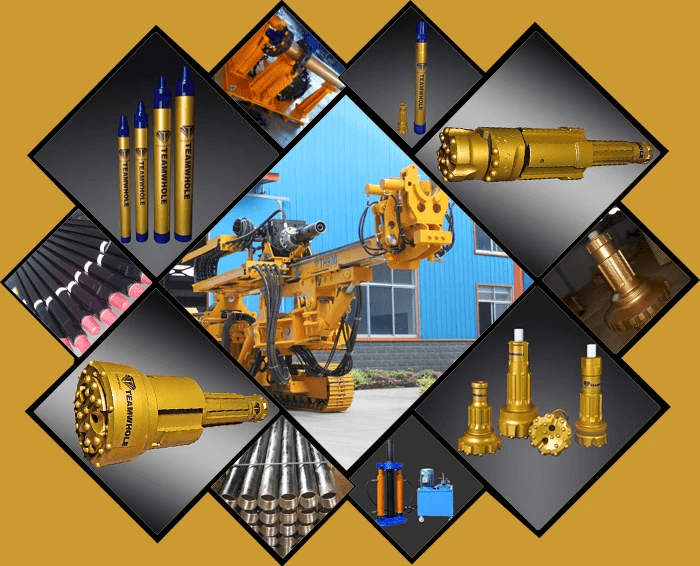

When it comes to precision drilling, nothing beats the importance of premium DTH bits and hammers. These powerful tools are essential for achieving accurate and efficient drilling results across various industries. From oil and gas exploration to mining and quarrying operations, DTH hammers are crucial in delivering exceptional performance and reliability.

Importance of Premium DTH Bits and Hammers

DTH (Down-The-Hole) drilling is a powerful technique used across various industries for tasks like mineral exploration and water well construction. However, its success hinges on the quality of the equipment. Here's why investing in premium DTH bits and hammers is crucial:

- Conquer Tough Terrain: Premium DTH hammers are built to handle challenging rock formations. Their advanced design ensures they can drill through hard surfaces efficiently, making them the ideal choice for complex projects.

- Long-lasting Durability: These tools are engineered to withstand extreme wear and tear. The high-quality materials and innovative construction resist fatigue, even under harsh conditions, minimizing downtime and replacement costs.

- Enhanced Drilling Speed: Premium DTH bits and hammers can significantly improve drilling speed. This translates to faster project completion times and increased productivity on the job site, allowing you to meet deadlines more efficiently.

Investing in premium DTH bits and hammers will give you a reliable and efficient drilling solution that tackles tough jobs while saving time and money in the long run.

Exploring the Versatility of DTH Hammers

One key factor that sets DTH hammers apart is their ability to handle a diverse range of drilling tasks, from shallow wells to deep boreholes. Their adaptability makes them an invaluable asset for any drilling project, offering the flexibility to tackle any challenge easily.

DTH hammers are also known for their durability and reliability, making them a cost-effective choice for drilling operations. Their robust construction and efficient energy transfer result in minimal wear and tear, reducing the need for frequent maintenance or replacement. This saves time and money and ensures uninterrupted drilling operations, making DTH hammers a preferred choice for demanding drilling projects.

Key Factors in Choosing the Right DTH Bit

Selecting the right DTH bit is essential for efficient and productive drilling. Here are several key factors to consider:

- Bit Head Design: The shape of the bit head, such as convex, flat face, or concave, influences how the bit breaks rock. Choose a design that complements the rock formation – flat or concave faces for softer rock, convex for harder formations.

- Carbide Inserts: The shape and grade of the carbide inserts on the bit head determine its penetration rate and wear resistance. Ballistic or semi-ballistic inserts are ideal for soft to medium rock, while domed inserts offer better durability in hard rock.

- Hammer Shank Compatibility: Ensure the DTH bit shank is compatible with your specific hammer drill for proper connection and transmission of impact energy.

- Material Composition: High-quality steel construction extends the bit's lifespan, minimizing downtime for replacements and maintenance.

- Flushing Hole Design: The design and placement of flushing holes on the bit head impact chip and debris removal. Effective flushing promotes smoother drilling and reduces bit wear.

By considering these factors and selecting the appropriate DTH bit for your specific application, you can optimize drilling performance, reduce costs, and ensure a successful project.

The Technology Behind Premium DTH Bits and Hammers

High Quality Alloy Steel and Advanced Heat-treatment

When it comes to the technology behind premium DTH bits and hammers, high-quality alloy steel is a game-changer. The advanced heat-treatment process ensures the steel is strong enough to withstand the toughest drilling conditions, providing durability and reliability for DTH hammer drilling projects. These bits and hammers are built to last, making them a cost-effective choice for any drilling operation.

In addition to the high-quality alloy steel and advanced heat treatment, the design of premium DTH bits and hammers also plays a crucial role in their performance. These tools are engineered with precision to optimize impact energy transfer, resulting in faster drilling speeds and reduced wear on the equipment. This innovative design ensures that drilling projects can be completed more efficiently, saving operators both time and money.

Diverse Line of DTH Bits from 3 to 47 in Diameter

The versatility of DTH bits is unmatched, with a diverse line ranging from 3 to 47 inches in diameter. This wide range allows for precision drilling in various rock formations, making it suitable for different industry applications. Whether it's small-scale or large-scale drilling projects, a DTH bit size is available to meet specific requirements, ensuring efficiency and accuracy in every drill.

In addition to the wide range of diameters available, DTH bits offer four head-face designs and two carbide shapes. This variety allows for customization based on specific drilling requirements, ensuring optimal performance in different geological conditions. Whether it's a flat face, convex, concave, or drop center design, spherical or ballistic carbide shapes, there's a DTH bit configuration to suit every drilling need. This level of customization contributes to the versatility and efficiency of DTH drilling across various industries.

Four Different Bit Head Face Designs and Two Different Carbide Shapes

Premium DTH bits come with four different bit head face designs and two different carbide shapes, offering flexibility in choosing the right tool. Whether it's flat face, concave face, convex face, or drop center face designs, each serves a specific purpose in achieving optimal drilling performance. With two different carbide shapes available – spherical and ballistic – users can match their needs for efficient drilling operations.

Remember that understanding the technology behind premium DTH bits and hammers is crucial in making informed decisions for your drilling projects. With high-quality alloy steel construction, diverse bit sizes, head face designs, and carbide shapes available, you can maximize efficiency while tackling any challenge in rock formations with ease!

Advantages of Using DTH Hammers for Precision Drilling

Extreme Protection Against Wear and Fatigue

DTH hammers offer unparalleled protection against wear and fatigue, thanks to their high-quality materials and advanced heat-treatment. This ensures that the hammers can withstand the toughest drilling conditions without compromising on performance or durability.

Versatility to Tackle Any Challenge and Rock Formations

One key advantage of using DTH hammers is their versatility in tackling any challenge and rock formations. Whether it's hard granite or soft limestone, DTH hammers are designed to deliver consistent performance across a wide range of drilling applications, making them the go-to choice for precision drilling projects.

Now that we've explored the extreme protection against wear and fatigue and the versatility to tackle any challenge and rock formations offered by DTH hammers, let's move on to discussing the factors to consider when selecting DTH bits and hammers.

Factors to Consider When Selecting DTH Bits and Hammers

Selecting the right DTH bits and hammers is essential for efficient and successful drilling projects. Here are key factors to consider:

- Hammer Shank Compatibility: Different shank designs offer varying levels of durability and compatibility with different drilling equipment. Choose a shank that can withstand the demands of your project and fit your drill rig.

- DTH Bit Design and Material: Precision drilling relies on the right DTH bit. Consider factors like bit head face design (flat, concave, etc.) and carbide shape (spherical, ballistic) to select a bit that effectively penetrates your target rock formation and maximizes productivity.

- DTH Hammer Price vs. Performance: While staying within budget is important, prioritize quality and performance. Premium DTH bits and hammers may have a higher upfront cost, but their durability, efficiency, and long-term benefits often outweigh the initial investment.

By carefully considering these factors, you can select DTH bits and hammers that optimize the success of your drilling project.

Applications of DTH Bits and Hammers in Various Industries

Oil and Gas Exploration

When it comes to oil and gas exploration, DTH hammers and bits are essential tools for efficient drilling in challenging terrains. DTH hammer drilling's precision drilling capabilities make it ideal for reaching deep underground reserves, while the durability of DTH bits ensures continuous operation even in the toughest rock formations.

In addition to their drilling capabilities, DTH hammers and bits offer minimal environmental impact during oil and gas exploration. By using precise drilling techniques, there is less disruption to the surrounding ecosystem, reducing the overall footprint of the operation. This is especially important in sensitive areas where conservation efforts are a priority, making DTH hammer drilling a responsible choice for companies in the oil and gas industry.

Mining and Quarrying Operations

DTH hammers' reliability and versatility shine through in mining and quarrying operations. These powerful tools can handle a wide range of rock types, making them invaluable for extracting valuable minerals and aggregates. With the right DTH hammer bits, mining and quarrying operations can achieve higher productivity and cost-efficiency.

DTH hammers are known for their durability and low maintenance requirements. They can handle a wide range of rock types and are a cost-effective choice for mining and quarrying operations, as they can withstand the rigors of heavy-duty use without frequent repairs or replacements. With minimal downtime and maintenance costs, businesses can maximize their productivity and profitability in the long run.

Geothermal and Water Well Drilling

Geothermal and water well drilling requires precision and endurance, which is where premium DTH bits and hammers excel. The ability to withstand extreme conditions while maintaining accuracy makes them indispensable for tapping into geothermal energy sources or accessing underground clean water reserves.

Companies can maximize their drilling efficiency by using premium DTH bits and hammers across these industries while minimizing downtime due to tool wear or breakage. Whether reaching deep into the earth for oil reserves or extracting valuable minerals from mines, the versatility of these tools makes them vital assets for various industrial applications.

Maximize Efficiency with the Right DTH Bit and Hammer

When it comes to precision drilling projects, it's crucial to make informed decisions by choosing the right DTH bits and hammers. By understanding the technology and advantages of DTH hammer drilling, you can maximize efficiency and explore endless possibilities for various industries.

Making Informed Decisions for Precision Drilling Projects

Selecting the right DTH bit and hammer is essential for successful drilling projects. By considering factors such as hammer shanks, precision drilling, and DTH hammer price, you can ensure that your project is completed accurately and efficiently. When choosing a DTH bit and hammer, it's important to also take into account the type of rock formation you'll be drilling into. Different formations require different types of bits and hammers for optimal performance, so understanding the geology of your drilling site is crucial. Additionally, considering the overall quality and durability of the equipment will help minimize downtime due to maintenance or replacement, ultimately maximizing efficiency in your drilling operations.

Using premium DTH bits and hammers maximizes drilling operations efficiency. These tools are essential for achieving optimal results because they offer extreme protection against wear and fatigue and versatility to tackle any challenge or rock formation. Furthermore, the advanced design of premium DTH bits and hammers ensures greater penetration rates, reducing overall drilling time and increasing productivity. Additionally, the precision engineering of these tools minimizes the risk of deviation, resulting in straighter boreholes and improved overall operational accuracy.

Exploring the Endless Possibilities with Premium DTH Bits and Hammers

The applications of DTH bits and hammers extend across various industries, such as oil and gas exploration, mining, quarrying operations, geothermal drilling, and water well drilling. The diverse range of DTH bits from 3 to 47 inches in diameter offers endless possibilities for precision drilling projects.

The versatility of premium DTH bits and hammers allows for efficient and accurate drilling in various geological formations, from soft to hard rock. This adaptability makes them an essential tool for any drilling project, whether it's in the rugged terrain of a mining site or the remote location of a geothermal exploration. With advanced designs and materials, these DTH bits and hammers are engineered to withstand high-impact conditions, ensuring durability and longevity in the field.