Introduction

Are you looking to take your drilling operations to the next level? Reverse circulation drilling might be the game-changer you've been searching for. This innovative method has revolutionized the industry's efficiency and cost-effectiveness, making it a popular choice for many companies. If you're considering investing in a reverse circulation drilling rig, it's essential to understand the ins and outs of this technique and the benefits it can offer.

Understanding Reverse Circulation Drilling

Reverse circulation drilling, also known as RC drilling, is a technique that involves using compressed air to extract rock samples from deep within the earth. This method allows for faster and more accurate drilling, making it ideal for various applications such as mineral and geotechnical investigations. With its ability to provide high-quality samples in a timely manner, RC drilling has become a preferred choice for many industry professionals.

Benefits of Using Reverse Circulation Drill

Reverse circulation (RC) drilling offers unique advantages for various applications, making it a valuable tool in geotechnical and environmental investigations. Here's a breakdown of its key benefits:

1. Enhanced Sample Recovery: RC drilling excels in retrieving high-quality samples compared to traditional drilling methods. This translates to obtaining more accurate data about the composition and properties of the subsurface, leading to:

- Improved decision-making: With a clearer picture of underground conditions, informed choices can be made regarding construction plans, resource exploration, and environmental assessments.

- Reduced project risks: Having reliable data upfront helps mitigate unforeseen challenges due to inaccurate subsurface information.

2. Efficiency and Cost-Effectiveness: RC drilling rigs are known for their:

- Faster drilling rates: This translates to quicker completion of projects, saving time and resources.

- Simplified logistics: The drilling process requires less water and produces smaller cuttings, simplifying on-site handling and disposal.

Reverse circulation drilling offers a combination of superior sample recovery, operational efficiency, and cost-effectiveness, making it a valuable choice for various exploration and investigation projects.

Choosing the Right RC Drilling Rig

Choosing the right reverse circulation (RC) drilling rig is essential for efficient and successful drilling operations. Here are some key factors to consider:

1. Project Requirements

- Purpose: Identify the primary purpose of your drilling project. Are you collecting mineral samples, performing geotechnical surveys, or extracting water?

- Depth and Diameter: Determine the depth and diameter of the boreholes you must create.

- Ground Conditions: Understand the geological makeup of your drilling site. Different rigs are suited for various rock formations.

2. Rig Specifications

- Size and Power: The rig's size and power should correspond to the project's depth and diameter requirements.

- Mobility: Consider the accessibility of your drilling location. For uneven terrain, opt for tracked rigs or truck-mounted rigs for easier transport.

3. Additional Factors

- Fuel Efficiency: Evaluate the rig's fuel efficiency to optimize operational costs.

- Budget: Drilling rigs are significant investments. Set a realistic budget and explore purchase or rental options based on your project needs.

By carefully assessing these factors, you can select an RC drilling rig that effectively addresses your project requirements and ensures a productive and cost-efficient drilling operation.

When selecting a reverse circulation drilling rig for sale, several factors must be considered. From the size and power of the rig to its compatibility with different rock formations, finding the right fit is crucial for achieving optimal results. With numerous options available on the market, including reputable brands like Tianhe offering top-of-the-line RC drill rigs, it's essential to research and choose a rig that aligns with your specific project requirements.

The Basics of Reverse Circulation Drilling

How Reverse Circulation Works

Reverse circulation drilling, or RC drilling, involves using a dual-wall drill pipe where the outer drill pipe returns the drilling fluid and cuttings. As the drill bit cuts into the rock formation, the cuttings are forced up through the inner tube by the drilling fluid, allowing for efficient sample recovery.

Reverse circulation drilling offers several advantages over other drilling methods. One key benefit is the efficient sample recovery that allows for a more accurate analysis of the drilled rock formation. Additionally, using a dual-wall drill pipe reduces the risk of sample contamination, ensuring that the samples collected represent the actual subsurface conditions. This method also minimizes waste and environmental impact by containing cuttings within the inner tube, making it a more sustainable drilling option.

Advantages of RC Drilling

RC drilling, also known as reverse circulation drilling, offers several advantages over other drilling methods due to its efficiency and reduced environmental impact.

Here are some of its key benefits:

- High-quality samples: RC drilling allows for collecting high-quality samples with minimal contamination. The reverse circulation process minimizes contact between the drilling fluid and the rock cuttings, preserving the sample's integrity for further analysis.

- Faster drilling: Compared to other techniques, RC drilling boasts faster penetration rates. This is due to the use of compressed air to remove cuttings, allowing quicker drilling and completion of projects.

- Deeper depths: RC drilling can reach significant depths, making it suitable for various exploration and mining applications. While not as deep as other methods, it can effectively drill up to 1,000 meters, depending on ground conditions.

- Reduced environmental impact: RC drilling minimizes its environmental footprint through several aspects. Its efficient cuttings containment system minimizes the risk of contamination and uses significantly less water than other drilling methods, making it a more sustainable option.

RC drilling is a valuable technique for various drilling applications due to its efficiency, effectiveness, and environmental consciousness.

Key Components of a RC Drill Rig

An RC drill rig is a machine specifically designed for drilling holes in the ground. These holes are commonly used in construction, mining, and environmental applications. To function effectively, an RC drill rig relies on several key components:

- Compressor: This component provides the air pressure required to flush cuttings, which are the fragmented pieces of rock removed during the drilling process.

- Cyclone: This component separates the cuttings from the drilling fluid, which cools and lubricates the drill bit.

- Sample Hose: This hose collects samples from below the ground for further analysis.

- Mast: This component supports and positions the drill string, which is a long, hollow tube with the drill bit attached, during operation.

These essential components work together to ensure efficient and precise drilling operations.

Selecting the Right Reverse Circulation Drilling Rig

When choosing the right reverse circulation drilling rig, several factors must be considered. First, you'll want to assess the type of terrain you'll be working on, as this will determine the size and power of the rig needed. Additionally, consider the depth and diameter of the holes you'll be drilling, as this will impact the capacity and capabilities required of your RC drill rig.

Factors to Consider in Choosing

an RC Drill Rig

Other important factors include the availability of spare parts and maintenance services for your chosen rig, as well as its fuel efficiency and overall operating costs. It's also crucial to assess the level of technical support the manufacturer or supplier provides, ensuring that you have access to assistance when needed. By carefully considering these factors, you can make an informed decision when selecting a reverse circulation drilling rig for sale.

Top Features to Look for in RC Drill Rigs

Choosing the right RC drill rig requires careful consideration of several crucial factors. Here's a breakdown of the key aspects to evaluate:

1. Application and Performance

- Drilling Depth and Diameter: Determine your boreholes' required depth and diameter.

- Ground Conditions: Select a rig suitable for the terrain, whether soft soil, hard rock, or a combination.

2. Mobility and Accessibility

- Site Access: Consider the size and maneuverability of the rig to navigate the drilling location.

- Transportation: Evaluate if the rig requires a trailer for transport or if it's self-propelled.

3. Operational Efficiency

- Fuel Efficiency: Choose a rig with good fuel economy to minimize running costs.

- Ease of Operation: Prioritize user-friendly controls and automation features for efficient operation.

4. Maintenance and Support

- Spare Parts Availability: Ensure easy access to replacement parts to minimize downtime.

- Manufacturer Support: Look for a manufacturer with reliable after-sales service and technical assistance.

By thoroughly evaluating these factors, you'll be well-equipped to make an informed decision and select the optimal RC drill rig for your needs. Investing in the right equipment can significantly enhance your drilling operation's efficiency and productivity.

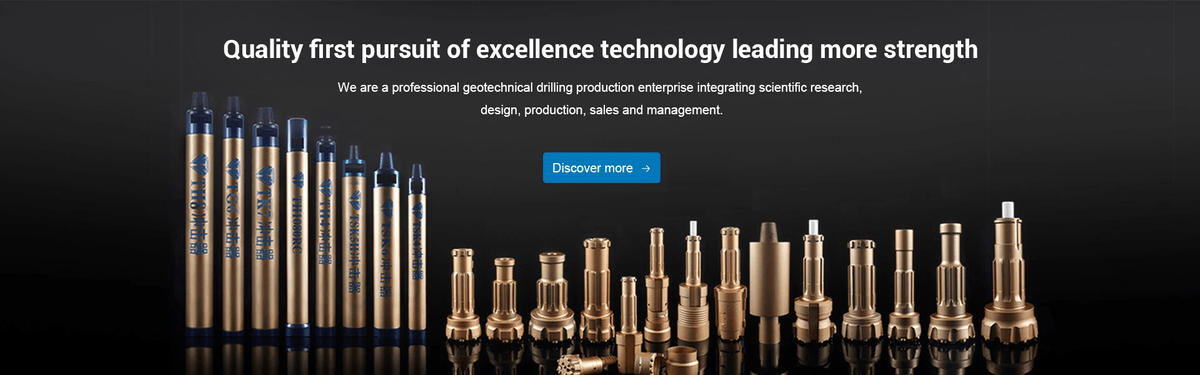

Popular Brands for RC Drill Rigs, including Tianhe

Tianhe is a leading brand that offers high-quality reverse circulation drilling rigs designed to deliver exceptional results across various applications. With a commitment to innovation and reliability, Tianhe's range of RC drill rigs includes models tailored to different project requirements. Whether you're seeking a compact rig for limited access areas or a heavy-duty option for large-scale operations, Tianhe has a solution to meet your needs.

In addition to offering a diverse range of RC drill rigs, Tianhe also provides comprehensive support and service to ensure its equipment continues performing at its best. From maintenance and repairs to technical assistance and training, Tianhe is committed to helping customers maximize the efficiency and longevity of their drilling rigs. This level of support can give you peace of mind, knowing that you have a reliable partner to rely on throughout the lifespan of your equipment.

Now that we've covered factors to consider when choosing an RC drill rig and highlighted some top features to look out for, let's explore how these considerations can inform your decision-making process when investing in this essential equipment.

The Process of Reverse Circulation Drilling

Step-by-Step Guide to RC Drilling

Reverse circulation drilling involves several key steps to ensure successful extraction of samples and data. First, the RC drill bit is lowered into the ground, and then high-pressure air forces the cuttings up through the inner tube of the drill string. The cuttings are then collected in a sample bag for analysis, providing valuable information for further exploration.

Safety Measures in RC Drilling Operations

When operating a reverse circulation drilling rig, it's crucial always to prioritize safety. This includes wearing appropriate personal protective equipment, maintaining a safe distance from moving parts, and conducting regular equipment checks to prevent malfunctions. Additionally, ensuring proper ventilation and adhering to established safety protocols can minimize the risk of accidents.

In addition to personal protective equipment and equipment checks, thorough training is important for all personnel involved in RC drilling operations. This includes proper instruction on safe operating procedures, emergency protocols, and hazard recognition. Ensuring that all team members are well-trained and knowledgeable about potential risks can significantly reduce the likelihood of accidents. Moreover, conducting regular safety meetings and refresher courses can help reinforce the importance of safety and keep everyone informed about any new developments or best practices in the industry.

Common Challenges in RC Drilling and How to Overcome Them

One common challenge in reverse circulation drilling is encountering unexpected obstructions or difficult formations underground. To overcome this, it's important to have a skilled team that can troubleshoot and adapt drilling techniques as needed. Additionally, using high-quality drill bits and maintaining regular maintenance on the RC drill rig can help mitigate potential challenges during operations.

Another challenge in RC drilling is maintaining consistent sample quality. To address this, it's crucial to carefully monitor drilling parameters and adjust as necessary to collect accurate samples. Additionally, utilizing proper sample handling and storage techniques can help preserve the integrity of the samples for analysis, minimizing potential errors or inconsistencies in data interpretation.

Applications of Reverse Circulation Drilling

Reverse circulation drilling has various applications across various industries, making it an essential method for extracting mineral resources, conducting environmental investigations, and even constructing geothermal wells. With its ability to efficiently recover high-quality samples and provide accurate data, RC drilling is highly beneficial for mining, geotechnical engineering, and environmental research industries.

Industries that Benefit from RC Drilling

Industries such as mining heavily rely on reverse circulation drilling, which can quickly and effectively extract core samples from deep within the earth. Geotechnical engineering firms also benefit from the precise data RC drilling provides for construction projects and soil analysis. Additionally, environmental research organizations utilize reverse circulation drilling to gather crucial information about groundwater resources and contamination levels.

Project Examples Using RC Drilling

In mining, RC drilling is commonly used in gold exploration projects to obtain accurate samples for resource estimation and reserve calculation. Geotechnical engineering firms utilize RC drilling in large-scale infrastructure projects to assess soil stability and composition before construction begins. Environmental research projects often use reverse circulation drilling to investigate groundwater contamination levels in areas affected by industrial activities.

Unique Uses of RC Drilling in Various Environments

Reverse circulation drilling (RC drilling) has proven invaluable in diverse environments such as deserts, rainforests, and even offshore locations due to its ability to efficiently collect high-quality samples in challenging conditions. In desert environments, where water resources are scarce, RC drilling explores potential groundwater reserves. In rainforests, it aids in studying soil composition without causing excessive disturbance to the delicate ecosystem.

By using reverse circulation drill rigs specifically designed for these environments, industries can maximize their efficiency while minimizing their impact on the surrounding ecosystems.

Investing in a Reverse Circulation Drilling Rig

Exploring the Market for RC Drill Rigs

When exploring the market for reverse circulation drilling rigs, it's essential to consider your projects' specific requirements. With many options available, it's important to research and compare different RC drill rigs to find the one that best suits your needs. Look for reputable suppliers who offer high-quality rigs at competitive prices.

Factors to Consider in Purchasing

an RC Drill Rig

When purchasing a reverse circulation drilling rig, several key factors should be considered. These include the depth and diameter of the holes you need to drill and the type of terrain and environmental conditions you'll be working in. Additionally, consider maintenance requirements, fuel efficiency, and overall durability to ensure you make a sound investment.

Finding the Best Deals on RC Drill Rigs, including Tianhe's RC Drilling Rigs

When searching for the best deals on reverse circulation drilling rigs, it is important to look for suppliers that offer high-quality equipment at competitive prices. Tianhe is known for providing top-notch RC drill rigs designed for efficiency and reliability. By exploring their range of products, you can find excellent deals on cutting-edge rigs that meet your drilling needs.

Maximize Your Results with Reverse Circulation Drilling

When maximizing your results with reverse circulation drilling,

investing in a high-quality RC drill rig that meets your specific project needs is essential. You can ensure efficient and effective drilling operations that yield the best possible results by choosing the right rig, such as a Tianhe reverse circulation drilling rig for sale.

Tips for Successful RC Drilling Projects

For successful RC drilling projects, it's crucial to prioritize safety and proper equipment maintenance. Regularly inspecting and maintaining your RC drill rig can help prevent costly downtime and ensure smooth operations. Additionally, staying updated on industry best practices and advancements in reverse circulation technology can further enhance the success of your drilling projects.

Choose the Right RC Drilling Rig for Your Needs

Selecting the right RC drill rig is a decision that should not be taken lightly. When evaluating different options for a reverse circulation drilling rig for sale, consider factors such as project requirements, terrain conditions, and budget constraints. Whether you're looking for a compact RC drill or a larger-scale rig, reputable brands like Tianhe offer a variety of reliable solutions to meet your specific needs.