Introduction

Choosing the right drill bit is crucial for success when it comes to rock drilling. With various types like tricone drill bits, triconic bits, and rotary drilling bits available, it's essential to understand their features and functions. Exploring the best drill bits for water well drilling is vital for efficient and effective operations. The importance of selecting the right drill bit for rock drilling cannot be overstated, as it directly impacts the project's outcome.

Understanding the Different Types of Rock Drilling Bits

Rock drilling bits come in different types, each with unique features and functions. There are options to suit various rock formations and drilling requirements, from the versatile tricone drill bit to the specialized triconic bit and rotary drilling bits. Understanding these differences is key to making informed decisions when selecting a drill bit for rock.

Exploring the Best Drill Bits for Water Well Drilling

Water well drilling requires precision and reliability, so exploring the best drill bits for this purpose is essential. The tricone bit, known for its versatility and efficiency in water well drilling, is a popular choice among professionals in the industry. Choosing the right tool for this critical task can make all the difference in achieving successful results.

Importance of Choosing the Right Drill Bit for Rock Drilling

Choosing the right drill bit for rock drilling ensures efficient and effective drilling operations while minimizing costs and downtime. Rock drilling presents unique challenges due to the hardness and variability of rock formations, necessitating careful consideration when selecting drill bits. The importance of choosing the right drill bit for rock drilling can be summarized as follows:

- Maximizing Penetration Rate: The right drill bit design and material selection optimize the penetration rate, allowing for faster drilling progress and increased productivity. Specialized carbide or diamond-tipped bits are often chosen for their superior hardness and wear resistance, enabling them to penetrate rock formations more effectively.

- Enhancing Tool Longevity: Proper selection of drill bits reduces equipment wear and tear, prolonging the bits' lifespan and the drilling rig. By choosing bits designed to withstand the abrasive nature of rock drilling, operators can minimize the frequency of bit replacements and associated downtime, ultimately reducing operational costs.

- Ensuring Stability and Accuracy: Drill bits must provide stability and accuracy during drilling to prevent deviation from the desired drilling path and maintain hole integrity. Choosing the right bit geometry, such as tapered or stepped designs, helps ensure proper alignment and reduces the risk of deviation or deflection when encountering uneven or fractured rock formations.

- Minimizing Drilling Fluid Consumption: Selecting drill bits with efficient cutting structures and hydraulic designs reduces the energy and drilling fluid consumption required for rock drilling. This lowers operational costs and minimizes environmental impact by reducing the volume of drilling fluids required and mitigating the risk of fluid loss into surrounding formations.

- Optimizing Performance in Various Rock Types: Different rock formations require different drill bit configurations and materials to achieve optimal performance. By considering factors such as rock hardness, abrasiveness, and fracture characteristics, operators can choose drill bits tailored to the specific geological conditions encountered, maximizing drilling efficiency and minimizing the risk of bit failure or premature wear.

Choosing the right drill bit for rock drilling is crucial for maximizing penetration rate, enhancing tool longevity, ensuring stability and accuracy, minimizing drilling fluid consumption, and optimizing performance in various rock types. By selecting drill bits tailored to the specific drilling conditions and requirements, operators can achieve efficient and cost-effective rock drilling operations with minimal downtime and environmental impact.

The Basics of Rock Drilling Bits

Rock drilling bits come in various types, each designed for specific drilling conditions and rock formations. The most common types include the tricone drill bit, triconic bit, and rotary drilling bits. Each type has unique features and functions that cater to different rock drilling needs.

Types of Rock Drilling Bits: Tricone Drill Bit, Triconic Bit, Rotary Drilling Bits

- The tricone drill bit is versatile for handling various rock formations, making it ideal for water well drilling projects.

- The triconic bit is designed for hard rock formations, offering superior performance in challenging drilling environments.

- Rotary drilling bits are suitable for softer formations and are widely used in geotechnical exploration.

Features and Functions of Each Type of Rock Drill Bit

- Tricone drill bits feature three cone-shaped heads with teeth that effectively crush hard rock formations. Tricone drill bits are known for their versatility and ability to handle various rock formations, from soft to hard. They are ideal for use in mixed formations where the ground can change from one type of rock to another.

- Triconic bits have a single cone with durable teeth that withstand intense pressure and heat during drilling. Triconic bits, on the other hand, are more specialized and excel in extreme drilling conditions where intense pressure and heat are common.

- Rotary drilling bits utilize a rotating motion to grind through softer formations easily. Rotary drilling bits offer easy grinding through softer formations, making them a popular choice for applications such as oil and gas exploration.

Advantages and Disadvantages of Different Rock Drill Bits

- While tricone drill bits offer versatility and adaptability to various rock types, they may require frequent maintenance due to their complex design.

- Triconic bits excel in hard rock environments but may struggle in softer formations.

- Rotary drilling bits are efficient for softer rocks but may not be suitable for harder formations due to their grinding action.

- Diamond drill bits are another option for hard rock drilling, as they are extremely durable and can maintain their sharpness for longer. However, they can be expensive and perform poorly in abrasive formations.

Choosing the Right Drill Bit for Water Well Drilling

Several crucial factors must be considered when selecting the right drill bit for rock. The hardness and abrasiveness of the rock formation, as well as the drilling depth and diameter, all play a significant role in determining the most suitable rock drill bit for the job.

Tianhe is renowned for its expertise in manufacturing high-quality rock drill bits designed to withstand the toughest drilling conditions. Focusing on research, design, production, sales, and management, Tianhe has established itself as a leader in providing reliable and durable drilling solutions.

The tricone bit is particularly well-suited for water well drilling due to its versatility and ability to handle various rock formations. Its three cone-shaped rotary cutters are ideal for achieving optimal performance in water well drilling projects.

The tricone bit's ability to handle various rock formations is key to its effectiveness for water well drilling. Whether drilling through soft sedimentary rock or hard, abrasive formations, the tricone bit offers reliable performance and consistent results. This versatility ensures that water well drilling projects can proceed smoothly and efficiently, regardless of the geological challenges.

Now that we've covered the importance of selecting the right drill bit for water well drilling and highlighted Tianhe's expertise in manufacturing top-notch rock drill bits, let's delve into key considerations for effective rock drilling.

Key Considerations for Effective Rock Drilling

When it comes to effective rock drilling, geotechnical factors play a crucial role in selecting the right drill bit. The hardness and abrasiveness of the rock formation, as well as its porosity and compressive strength, are all key considerations that influence the choice of rock drilling bits. Tianhe's expertise in understanding these geotechnical factors ensures that their drill bits are designed to meet the specific challenges of different rock formations.

Geotechnical Factors that Influence the Selection of Drill Bits

The hardness and abrasiveness of the rock formation are crucial factors when selecting a drill bit for rock drilling. For hard and abrasive formations, tricone drill bits or triconic bits are often preferred due to their durability and ability to withstand tough conditions. On the other hand, for softer formations, rotary drilling bits may be more suitable for efficient penetration. Tianhe's range of rock drill bits is designed to meet these diverse geotechnical challenges, ensuring optimal performance in various rock formations.

Tips for Maximizing the Efficiency of Rock Drill Bits

To maximize the efficiency of rock drill bits, it's essential to consider factors such as proper lubrication, correct drilling speed, and regular maintenance. Using high-quality drilling fluids can help reduce friction and heat generation during drilling operations, prolonging the lifespan of the drill bit. Additionally, maintaining an optimal drilling speed based on the specific characteristics of the rock formation can prevent premature wear and tear on the drill bit. Tianhe provides comprehensive guidance on these best practices to ensure maximum efficiency when using their rock drill bits.

Case Studies of Successful Water Well Drilling Projects

Successful water well drilling projects have relied on Tianhe's expertise in providing high-quality tricone bits for challenging geological conditions. From hard limestone formations to softer sandstone layers, Tianhe's range of tricone drill bits has consistently delivered exceptional performance in various water well drilling projects worldwide. These case studies testify to Tianhe's commitment to providing reliable solutions for effective rock drilling across diverse geotechnical environments.

With a thorough understanding of geotechnical factors influencing drill bit selection and a proven track record in successful water well drilling projects, Tianhe stands out as a trusted partner in delivering superior solutions for effective rock drilling operations.

The Significance of Proper Maintenance for Rock Drill Bits

Proper maintenance is crucial for extending the lifespan of rock drill bits. Regularly cleaning and inspecting the bits can prevent wear and tear, ensuring they remain in top condition for longer. Storing them in a dry, cool place is also important to prevent rust and corrosion.

Best Practices for Extending the Lifespan of Drill Bits for Rock

To maximize the lifespan of rock drill bits, using them at the correct speed and pressure is essential based on the type of rock being drilled. Additionally, sharpening or reconditioning the bits when necessary can help maintain their effectiveness and efficiency.

In addition to using the correct speed and pressure, ensuring that the drill bits are properly lubricated during operation is crucial. Lubrication helps reduce friction and heat, which can contribute to premature wear and tear on the bits. Regularly checking and maintaining the lubrication system will help extend the lifespan of the drill bits and improve overall drilling performance.

Tianhe's Recommendations for Maintaining Rock Drill Bits

Tianhe recommends following a regular maintenance schedule, including cleaning, inspecting, and reconditioning as needed. They also offer guidance on proper storage to prevent damage from environmental factors such as moisture and extreme temperatures.

Common Mistakes to Avoid When Handling Drill Bits for Rock

Common mistakes when handling rock drill bits include using them at incorrect speeds or pressures, neglecting proper cleaning and inspection routines, and storing them in unsuitable conditions. These mistakes can lead to premature wear and reduced performance.

Conclusion

In conclusion, choosing the right rock drill bit is crucial for the success of water well drilling projects. Whether tricone drill bit, triconic bit, or rotary drilling bits, Tianhe offers superior solutions for rock drilling needs. You can ensure efficient and effective rock drilling operations by making informed decisions and partnering with Tianhe.

Ensuring Success in Water Well Drilling with the Right Rock Drill Bit

Selecting the appropriate drill bit for rock is essential to successfully drilling water well. With Tianhe's expertise in manufacturing high-quality rock drill bits, you can trust that you are using the best tools for the job. Understanding the features and functions of different rock drill bits allows you to make informed decisions that lead to successful drilling operations.

The right rock drill bit can make all the difference in water well drilling. Tianhe's high-quality rock drill bits are designed to withstand the toughest rock formations, ensuring you can drill confidently and precisely. By choosing Tianhe as your partner in superior rock drill bit solutions, you can trust that you are using the best tools for the job, giving you peace of mind throughout the drilling process.

Tianhe: Your Partner in Superior Rock Drill Bit Solutions

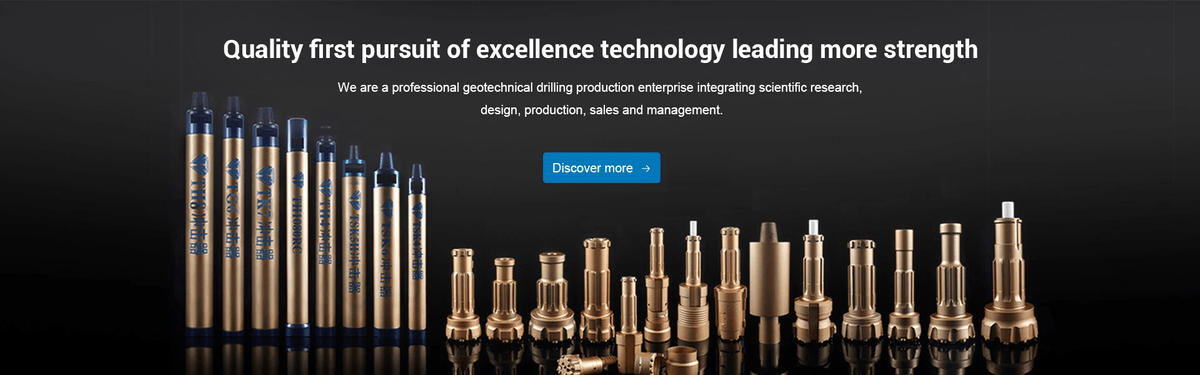

Tianhe is a professional geotechnical drilling manufacturer specializing in research, design, production, sales, and management of rock drill bits. Focusing on quality and innovation, Tianhe provides superior solutions for all your rock drilling needs. Trust Tianhe to deliver reliable and durable drill bits that ensure efficiency and effectiveness in water well drilling projects.

Tianhe's commitment to quality and innovation extends beyond producing rock drill bits. The company also invests heavily in research and design, constantly seeking new and improved solutions for rock drilling challenges. This dedication to staying at the forefront of technological advancements ensures that customers can always rely on Tianhe for the most cutting-edge and effective drilling tools.

Making Informed Decisions for Rock Drilling Success

In rock drilling projects, making informed decisions is key to achieving success. Consider factors such as geotechnical influences and maintenance practices to maximize the efficiency of your drill bits for rock. By avoiding common mistakes and following the best practices recommended by Tianhe, you can ensure long-lasting performance from your rock drill bits.

When it comes to rock drilling projects, making informed decisions is key to achieving success. Consider factors such as geotechnical influences and maintenance practices to maximize the efficiency of your drill bits for rock. By avoiding common mistakes and following the best practices recommended by Tianhe, you can ensure long-lasting performance from your rock drill bits. Additionally, staying updated on the latest advancements in rock drilling technology can provide valuable insights into improving productivity and reducing project downtime. Embracing drilling methods and equipment innovation can lead to significant cost savings and improved overall performance.