Introduction

Are you curious about the world of drilling? In this comprehensive guide, we will delve into the fascinating realm of rotary and DTH drilling. We'll explore the key differences between these two techniques and their impact on the mining and construction industries.

Understanding Rotary and DTH Drilling

When it comes to drilling, two main methods stand out: rotary drilling and down the hole (DTH) drilling. While both are essential in various applications, they each have unique characteristics that set them apart.

Exploring the Key Differences

From the equipment used to the drilling process itself, there are significant differences between rotary and DTH drilling. Understanding these disparities is crucial for making informed decisions in mining and construction projects.

The Impact on Mining and Construction

The choice between rotary and DTH drilling can have a profound impact on mining operations and construction projects. It's important to consider factors such as efficiency, cost-effectiveness, and environmental sustainability when deciding which method to use.

What is Rotary Drilling?

Rotary drilling is a versatile method used in various soil types, from soft to hard formations. This technique is commonly utilized in water well drilling, providing access to clean and safe drinking water for communities around the world. The equipment and process overview of rotary drilling involves a rotating drill bit attached to a drill string, allowing for efficient penetration into the ground.

Versatility in Various Soil Types

Rotary drilling offers versatility in tackling different soil types, making it suitable for a wide range of geological conditions. Whether it's soft clay or hard rock formations, rotary drilling can adapt to the specific requirements of each project. This flexibility makes it an ideal choice for construction and mining operations where the ground composition can vary significantly.

Furthermore, rotary drilling's adaptability extends to water well drilling, where it can efficiently handle various soil types and geological conditions. This makes it a preferred method for accessing groundwater in different locations, ensuring that water wells can be drilled effectively regardless of the ground composition. The versatility of rotary drilling in water well projects showcases its reliability and effectiveness in providing access to essential resources.

Utilization in Water Well Drilling

One of the key applications of rotary drilling is in water well drilling projects. By using this method, drillers can reach deep aquifers and underground water sources to provide essential access to clean water for communities and agricultural purposes. Rotary drilling's ability to penetrate through different layers of soil makes it an effective solution for addressing water scarcity issues.

Equipment and Process Overview

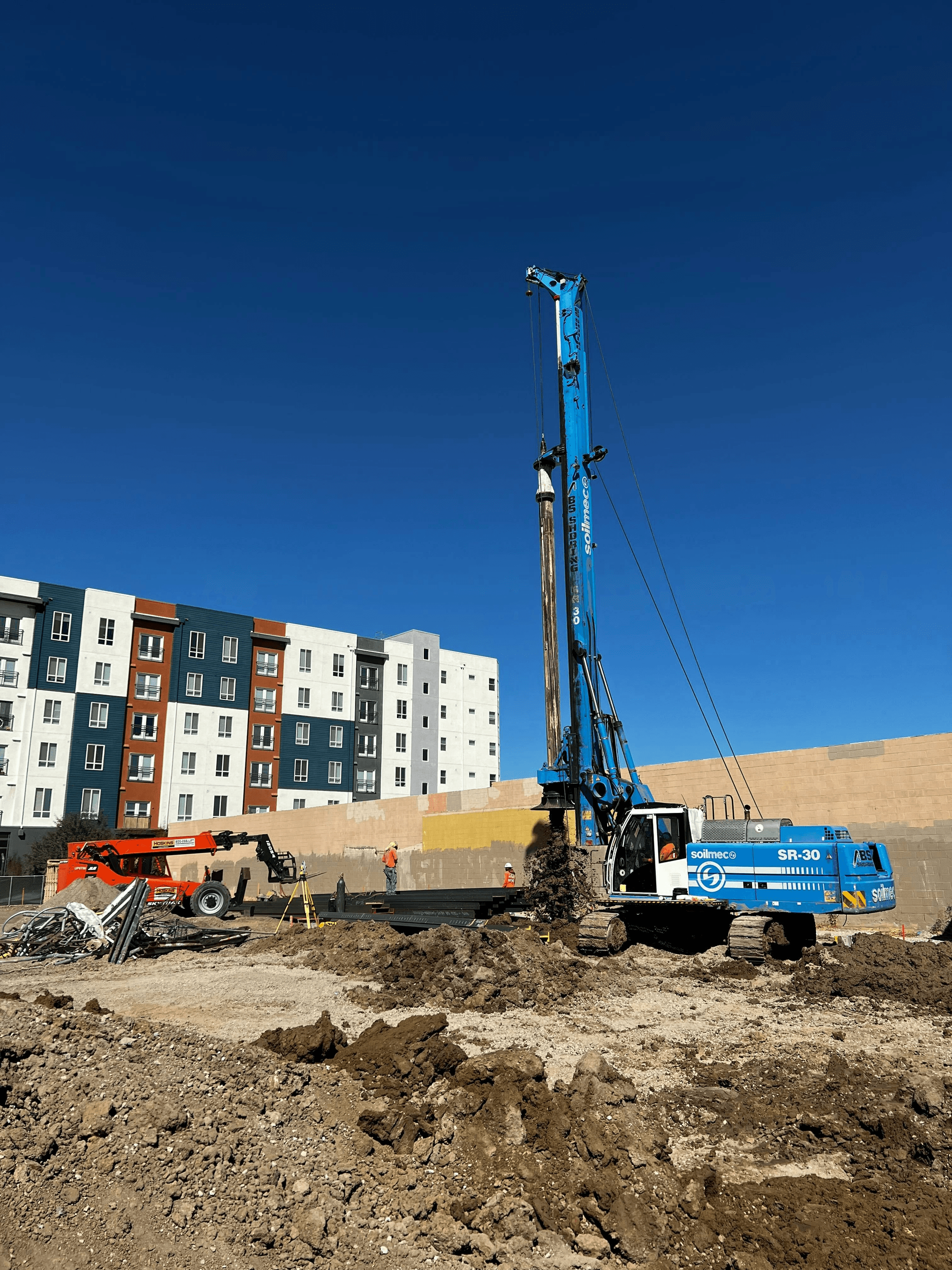

The equipment used in rotary drilling includes a rotary rig that houses the necessary machinery for driving the drill string into the ground. The process involves continuous rotation of the drill bit while applying downward pressure, allowing for efficient borehole creation. This method requires skilled operators and maintenance to ensure smooth operation throughout the drilling process.

The rotary rig used in drilling operations is equipped with a powerful engine to drive the drill string into the ground with precision and force. As the drill bit rotates continuously, it creates a smooth and uniform borehole, allowing for efficient extraction of core samples or installation of casings. Skilled operators are essential to monitor the drilling process, adjusting pressure and speed as needed to ensure optimal performance and safety.

What is Down the Hole (DTH) Drilling?

DTH drilling, also known as down the hole drilling, is a method used in the mining industry to penetrate hard rock formations. This technique involves a hammer that is located behind the drill bit and delivers powerful blows directly to the rock, making it an ideal choice for challenging geological conditions.

Application in Mining Industry

DTH drilling is widely used in the mining industry for its ability to efficiently penetrate hard rock formations. This method allows for faster and more precise drilling, making it an essential tool for extracting valuable minerals from deep within the earth. In addition to its speed and precision, DTH drilling also minimizes the potential for deviation, ensuring that miners can target specific mineral deposits with accuracy. Furthermore, this method reduces the amount of waste generated during the drilling process, leading to a more sustainable and environmentally friendly mining operation.

Advantages in Hard Rock Penetration

One of the main advantages of DTH drilling is its effectiveness in penetrating hard rock formations. Unlike other methods, DTH drilling can easily handle tough geological conditions, making it a preferred choice for mining operations where traditional drilling techniques may fall short.

Additionally, DTH drilling is known for its high penetration rates, allowing for quicker and more efficient drilling in hard rock formations. This can significantly reduce project timelines and costs, making it an attractive option for construction and mining companies looking to maximize their resources. The ability to penetrate hard rock quickly also minimizes the risk of equipment wear and tear, leading to lower maintenance and replacement costs in the long run.

Role in Foundation Construction

In addition to its application in mining, DTH drilling also plays a crucial role in foundation construction. The ability to penetrate hard rock formations with precision makes DTH drilling an invaluable tool for creating stable and secure foundations for various structures such as buildings, bridges, and dams.

Is DTH Drilling Better Than Rotary Drilling?

A Closer Look at Speed and Efficiency

When comparing DTH drilling to rotary drilling, one of the key factors to consider is speed and efficiency. DTH drilling is known for its ability to penetrate hard rock formations at a faster rate than rotary drilling, making it a preferred choice in mining and construction projects. The use of down the hole hammers enables rapid penetration, resulting in increased productivity and reduced project timelines.

Environmental Impact and Sustainability

In terms of environmental impact and sustainability, DTH drilling offers several advantages over rotary drilling. With its precise and controlled operation, DTH drilling minimizes disturbances to the surrounding environment, making it an eco-friendly option for various applications. Additionally, the efficient use of resources and reduced waste generation contribute to the overall sustainability of DTH drilling practices.

Cost-Effectiveness Comparison

When it comes to cost-effectiveness, DTH drilling proves to be a competitive choice compared to rotary drilling. While initial investment costs may be higher for DTH equipment, the long-term benefits in terms of speed, efficiency, and minimal maintenance requirements make it a cost-effective solution for mining and construction projects. The overall lower operational costs further contribute to the economic viability of DTH drilling.

Now that we've delved into the comparison between DTH and rotary drilling in terms of speed, efficiency, environmental impact, sustainability, and cost-effectiveness, let's explore another critical aspect - understanding what exactly a down the hole hammer is and its significance in modern-day drilling practices.

What is a Down the Hole Hammer?

A down the hole hammer, also known as a DTH hammer, is a drilling tool used in down the hole drilling. It operates by using compressed air to drive a piston against the drill bit, creating powerful impact energy for efficient rock penetration. This technology is widely utilized in mining, construction, and water well drilling due to its ability to handle hard rock formations with ease.

Understanding the Technology

The DTH hammer consists of a valve system that controls airflow and pressure, a piston that strikes the drill bit, and an outer casing to contain the impact energy. This innovative design allows for deep hole drilling in challenging terrains, making it an indispensable tool for various industries. The technology behind DTH hammers has evolved over the years to enhance performance and durability, ensuring reliable operation in demanding conditions.

Importance of DTH Hammer Supplier

Choosing a reputable DTH hammer supplier is crucial for obtaining high-quality equipment and reliable technical support. A trusted supplier offers expertise in selecting the right hammer for specific applications, providing maintenance services, and delivering timely assistance when needed. Partnering with an experienced supplier ensures seamless operations and minimizes downtime due to equipment issues.

Exploring the Price Range

The price range for DTH hammers varies based on factors such as size, brand, and additional features. While initial costs may seem higher compared to other drilling methods, the long-term benefits of improved productivity and reduced maintenance expenses make it a worthwhile investment for many businesses. It's essential to consider overall value rather than just upfront costs when evaluating different options.

Remember that choosing between down the hole (DTH) drilling and other methods depends on your specific needs and project requirements. However, understanding how DTH hammers work can help you make an informed decision about which drilling technique is best suited for your operations.

DTH Hammer Drilling Techniques

Case Studies and Success Stories

One notable case study in the mining industry showcases the efficiency of DTH hammer drilling in hard rock excavation, resulting in increased productivity and cost savings. Success stories also highlight the versatility of DTH drilling in foundation construction, proving its reliability in various soil conditions.

Water Well Drilling Hammer Applications

DTH hammers have become increasingly popular in water well drilling due to their ability to penetrate hard formations with ease, providing a more efficient and reliable solution compared to traditional drilling methods. The adaptability of DTH hammers makes them ideal for accessing water sources in challenging geological environments.

Innovations and Future Developments

Innovations in DTH hammer technology continue to drive advancements in drilling techniques, with a focus on enhancing penetration rates, durability, and overall performance. Future developments aim to further improve efficiency and reduce environmental impact, positioning DTH hammer drilling as a sustainable solution for various industries.

Remember that it's important to always consider the specific needs of your project when choosing between rotary and down the hole (DTH) drilling methods. Each has its own advantages depending on factors such as soil type, project scale, and budget constraints. As innovations continue to shape the future of DTH hammer drilling, it's essential to stay informed about the latest developments and technologies available from reputable suppliers like TEAMWHOLE.

Conclusion

Pros and Cons of Rotary and DTH Drilling

When it comes to down the hole drilling, both rotary and DTH drilling have their own set of advantages and disadvantages. Rotary drilling is versatile and can be used in various soil types, while DTH drilling is better suited for hard rock penetration. However, rotary drilling may be more cost-effective in certain situations, while DTH drilling offers faster speed and efficiency.

Making an Informed Decision

In order to make an informed decision between rotary and DTH drilling, it's important to consider the specific requirements of your project. Factors such as soil type, rock hardness, project timeline, and budget should all be taken into account when choosing the appropriate drilling method. By carefully evaluating these factors, you can ensure that you select the most suitable technique for your needs.

TEAMWHOLE: The Future of DTH Hammer Drilling

As the demand for down the hole hammer drilling continues to grow in industries such as mining and construction, it's crucial to partner with a reliable DTH hammer supplier like TEAMWHOLE. With their expertise in providing high-quality DTH hammers at competitive prices, they are paving the way for future innovations in DTH hammer technology.

With a thorough understanding of both rotary and down the hole (DTH) drilling techniques, as well as insights into the future of DTH hammer technology with TEAMWHOLE as a leading supplier, you are now equipped to make informed decisions when it comes to selecting the right method for your mining or construction projects.