Introduction

In the oil and gas industry, selecting the right oilfield pipe is crucial for ensuring the success and safety of operations. The choice of oilfield pipe can significantly impact the overall efficiency and longevity of drilling projects. Therefore, it's essential to carefully consider various factors before deciding which type of pipe to use.

Understanding the Importance of Selecting the Right Oilfield Pipe

Choosing the right oilfield pipe is vital because it directly affects the performance and reliability of drilling operations. The right pipe can withstand harsh conditions, resist corrosion, and maintain structural integrity over time. This ensures that operations run smoothly without unexpected downtime or costly repairs.

Factors to Consider When Choosing Oilfield Pipe

Choosing the right oilfield pipes is crucial for safe and efficient operation. Here's a breakdown of key factors to consider:

- Material Composition: Different materials offer varying strength, corrosion resistance, and weight. Standard options include steel, stainless steel, and fiberglass, each with advantages and disadvantages for specific applications.

- Quality Standards: Ensure the pipes meet relevant industry standards like API (American Petroleum Institute) for guaranteed quality and performance.

- Project Requirements: Consider pipe diameter, length, and thread type to ensure compatibility with your existing infrastructure and intended use.

- Pressure Rating: The pipes must withstand the expected pressure within the system. Choose pipes with a pressure rating exceeding the maximum operational pressure.

- Temperature Resistance: Pipes must be able to handle the operating temperature range, whether extreme heat or cold, to avoid deformation or failure.

- Environmental Conditions: Corrosive elements, abrasive substances, or high-velocity flow can impact pipe selection. Opt for materials with the necessary resistance to these conditions.

By carefully considering these factors, you can select oilfield pipes that guarantee optimal performance and longevity for your project.

The Impact of Using the Wrong Oilfield Pipe

Choosing the right oilfield pipe is critical for a successful drilling project. Improper selection can lead to negative consequences, impacting safety, efficiency, and the environment.

- Safety Compromises: Using the wrong pipe can lead to leaks, equipment failure, and compromised safety measures. This can put workers at risk and potentially cause serious accidents.

- Environmental Hazards: Leaks from incompatible pipes can contaminate soil and water with hazardous materials, posing a serious environmental threat.

- Costly Downtime: Leaks and equipment failure caused by the wrong pipe can lead to extensive downtime, halt operations, and incur significant financial losses.

- Regulatory Issues: Improper pipe selection can result in improper compliance with safety regulations, which can result in fines and project delays.

- Decreased Productivity: Pipes unsuitable for the drilling conditions can slow down the entire process, leading to missed deadlines and inefficiency.

By carefully selecting pipes designed for the project's specific needs, drilling operations can run smoothly, safely, and efficiently.

Types of Oilfield Pipes

When selecting the right oilfield pipe for sale, it's crucial to understand the different types available in the market. Seamless pipes are manufactured without any welding seam, providing maximum strength and reliability, making them ideal for high-pressure applications in the oil and gas industry. On the other hand, welded pipes are constructed by welding a flat plate of steel into a cylindrical shape, offering cost-effective solutions for various drilling and production operations.

Seamless vs. Welded Pipes

Seamless pipes are known for their uniform structure and ability to withstand extreme pressure, making them a popular choice for oilfield applications where safety and durability are paramount. In contrast, welded pipes are more economical and readily available, suitable for less demanding operations that do not require as much strength or pressure resistance. While seamless pipes offer superior strength and reliability, welded pipes can be cost-effective for projects with lower pressure requirements. This makes them ideal for various applications in various industries, providing flexibility and affordability without compromising quality.

Drill Pipe vs. Casing Pipe

Drill pipe is designed to transmit torque while drilling a wellbore and must withstand high internal and external pressure and bending loads. Casing pipe lines the borehole of an oil or gas well to prevent contamination of the surrounding groundwater and support the wellstream.

Drill and casing pipes serve different purposes in the oil and gas industry, but both are essential for drilling and extraction. While the drill pipe is focused on transmitting torque and withstanding high pressure and bending loads during drilling, the casing pipe protects the surrounding groundwater from contamination. It provides structural support for the well stream. These two types of pipes work together to ensure the success and safety of oil and gas operations.

Coated vs. Uncoated Pipes

Coated oilfield pipes offer enhanced protection against corrosion and abrasion, extending their lifespan in harsh environments such as offshore drilling rigs or corrosive soil conditions. Uncoated pipes provide cost-effective solutions for less demanding applications with minimal environmental exposure.

Coated pipes are often lined with epoxy or polyethylene, providing a barrier that shields the metal from corrosive elements. This extra layer of protection extends the pipes' lifespan and reduces maintenance costs over time. In contrast, uncoated pipes may be more susceptible to corrosion and abrasion, requiring frequent replacements and repairs in harsh environments.

Quality Standards for Oilfield Pipes

When sourcing oilfield pipes for sale, it's crucial to ensure they meet industry quality standards. One of the most important certifications to look for is the API certification, which ensures that the pipes are manufactured in compliance with stringent industry standards.

API Certification

The American Petroleum Institute (API) benchmarks oilfield pipe quality and safety. When looking for drill pipe or oil field pipe for sale, it's essential to prioritize API-certified pipes. This certification guarantees that the pipes have undergone rigorous testing and adhere to strict manufacturing standards.

Material Composition

Another critical aspect of quality standards is the material composition of the oilfield pipes. High-quality, durable materials such as alloy steel are essential for withstanding the harsh conditions of oilfield operations. It's important to thoroughly assess the material composition of any oil field pipe for sale to ensure longevity and reliability.

Inspection and Testing Processes

Inspection and testing processes are vital in maintaining quality standards for oilfield pipes. Reputable suppliers conduct thorough inspections and testing procedures to identify any defects or weaknesses in the pipes before they are offered for sale. This ensures that only high-quality, reliable pipes enter the market.

With a clear understanding of these quality standards, buyers can confidently navigate their options when seeking out used oilfield pipe near me or used drill pipe for sale on Craigslist.

Sourcing Oilfield Pipe for Sale

When looking for reliable suppliers, it's crucial to do thorough research and gather recommendations from trusted sources. Check for supplier certifications and customer reviews to ensure credibility and product quality. Look for suppliers that offer a wide range of oilfield pipes, including drill pipes for sale, to have options that suit your specific needs.

Reliable Suppliers in the Industry

Reliable suppliers often have a strong track record of delivering high-quality oilfield pipes that meet industry standards. Look for suppliers with extensive experience and a reputation for providing durable and reliable products. Consider reaching out to industry professionals or associations for recommendations on reputable suppliers.

Considerations for New vs. Used Pipes

When considering new vs. used oilfield pipes for sale, it is essential to weigh the cost savings against potential risks. While used pipes may come at a lower price, they may also have hidden defects or reduced longevity. New pipes offer the advantage of being pristine with full manufacturer warranties, providing peace of mind for long-term investments.

Local vs. International Suppliers

When it comes to oilfield pipe, choosing the right supplier is just as crucial as selecting the appropriate pipe type. Both significantly impact your project's success and efficiency. Here's a breakdown of the key considerations when deciding between local and international oilfield pipe suppliers:

- Delivery Speed vs. Product Variety: Local suppliers often offer faster delivery times due to shorter transportation distances. However, international suppliers may provide a wider selection of products, potentially including specialized options not readily available locally.

- Cost Comparison: While local suppliers might seem more affordable initially, shipping costs are a factor when considering international options. Additionally, international suppliers may offer more competitive pricing due to economies of scale.

- Regulations and Lead Times: International purchases involve import/export regulations that can add complexity and potentially extend lead times. When working with international suppliers, be sure to factor in these additional considerations.

Ultimately, the best choice depends on your specific needs. Local suppliers might be ideal if tight project timelines and readily available options meet your requirements. However, international suppliers are worth exploring if you require a broader product range or potentially more competitive pricing, considering potential lead time and regulatory hurdles.

Cost and Longevity Comparison

When considering oilfield pipes for sale, the long-term investment benefits must be considered. While upfront costs may seem daunting, investing in high-quality oilfield pipes can result in extended longevity and reduced maintenance expenses. By prioritizing durability and reliability, companies can avoid the hassle of frequent replacements and unexpected downtime, ultimately saving money in the long run.

Long-term Investment Benefits

When selecting oilfield pipes, consider the initial price and the long-term value they provide. High-quality pipes offer several advantages:

- Fewer replacements and repairs: Built to last, they minimize the need for frequent replacements and repairs, saving you money in the long run.

- Reduced downtime: Fewer repairs translate to less downtime for your oilfield operations, allowing for smoother and more efficient functionality.

- Increased productivity: With less downtime, your oilfield can produce more oil, maximizing your return on investment.

In conclusion, while high-quality oilfield pipes may seem like a higher upfront cost, the long-term savings in replacements, repairs, and downtime make them a wise investment for any oilfield operation.

Balancing Cost and Quality

While cost is a significant factor when purchasing oilfield pipes for sale, balancing cost and quality is essential. Opting for cheaper options may seem appealing initially, but they often come with lower durability and a shorter lifespan. By prioritizing quality over cost, companies can ensure that their operations run smoothly without constant disruptions due to pipe failure.

Avoiding Common Pitfalls in

Cost-Saving

One common pitfall when purchasing oilfield pipe for sale is focusing solely on cost-saving measures without considering the long-term implications. Choosing used or low-quality pipes may seem like a way to cut costs, but they often lead to higher maintenance expenses and frequent replacements in the future. To avoid these pitfalls, it's important to prioritize value over immediate savings.

Remember that investing in high-quality oilfield pipes for sale is an investment in the efficiency and longevity of your operations. By carefully considering the long-term benefits, balancing cost with quality, and avoiding common pitfalls in cost-saving measures, companies can make informed decisions that benefit their bottom line while ensuring reliable oilfield performance.

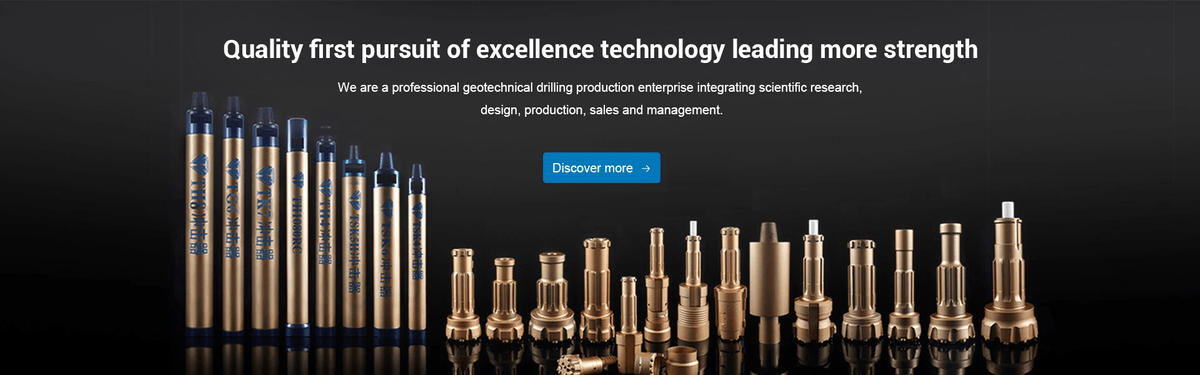

Teamwhole's Diverse Line of Oilfield Pipes

When finding the right oilfield pipe for sale, Teamwhole offers diverse options to meet your specific needs. Whether you're looking for a drill pipe or oil field pipe for sale, we have you covered with our extensive inventory and high-quality products.

Range of DTH bit diameters

Teamwhole provides a wide range of DTH bit diameters to ensure you can find the perfect fit for your drilling operations. From smaller diameters for precision work to larger sizes for more heavy-duty applications, we have the right options to meet your requirements.

High-quality alloy steel and advanced heat-treatment

Our oilfield pipes are constructed using high-quality alloy steel and undergo advanced heat-treatment processes to ensure durability and reliability in even the most demanding conditions. You can trust that our pipes are built to withstand the rigors of oilfield operations.

Different bit head face designs and carbide shapes

With various bit head face designs and carbide shapes, Teamwhole's oilfield pipes offer versatility and customization options to optimize performance based on specific drilling needs. Whether you require enhanced penetration rates or a longer bit life, we have your solutions.

In conclusion, when searching for a used oilfield pipe or new drill pipe for sale near me, Teamwhole stands out as a reliable supplier offering top-notch products backed by quality and expertise in the industry. With our diverse line of oilfield pipes, you can be confident in finding the right solution to maximize efficiency and longevity in your operations.

Conclusion

When it comes to oilfield pipe for sale, longevity and efficiency are key factors to consider. Investing in high-quality oil field pipes for sale will save you money in the long run and ensure that your operations run smoothly without any unexpected hiccups.

Choosing the right oil field pipe for sale is crucial for the success of your drilling operations. Quality and reliability should be non-negotiable when selecting oilfield pipes for sale near me. Don't settle for anything less than top-notch pipes that meet industry standards.

When considering whether to use a drill pipe on Craigslist or a new oil field pipe for sale, carefully weigh the pros and cons. Make informed decisions based on the specific needs of your drilling projects and always prioritize quality over cost-saving measures that could cost you more in the long run.

Remember, choosing the right oil field pipe for sale can significantly impact your operations. Don't cut corners when sourcing reliable, durable pipes that will stand the test of time. Your investment in quality will pay off in terms of efficiency, safety, and overall success in your drilling endeavors.