Introduction

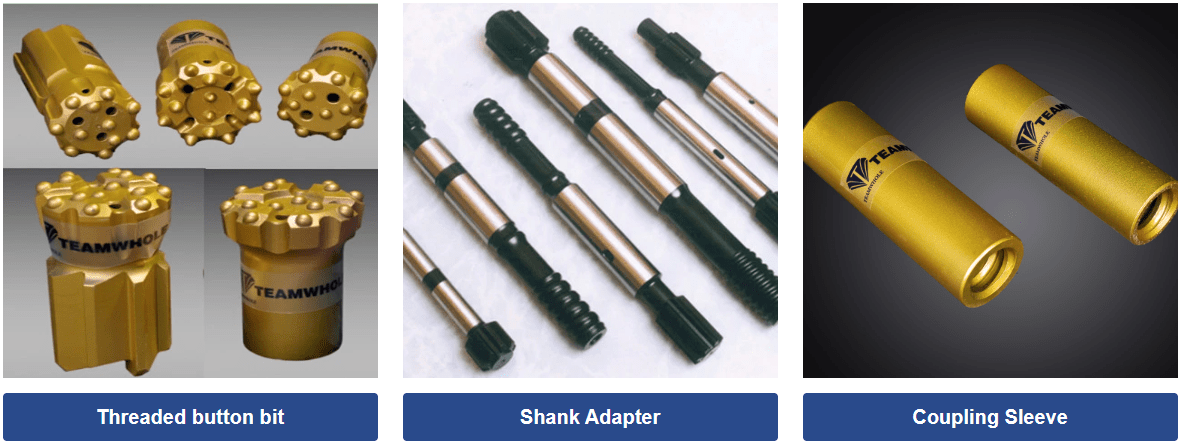

Are you familiar with the crucial role that shank adapters play in the mining industry? Shank adapters are essential components that connect drill bits to drilling equipment, ensuring efficient and effective operations. Without these adapters, the drill bits could not perform their function effectively, resulting in decreased productivity and increased costs for mining companies. Let's delve into the significance of shank adapters and how they are integral to the mining industry.

Understanding Shank Adapters

Shank adapters provide a secure connection between drill bits and drilling equipment. They come in various sizes and designs to accommodate different types of drill bits, ensuring compatibility and optimal performance. These adapters are crucial for maintaining stability and precision during drilling operations, ultimately contributing to the overall success of mining projects.

Importance of Shank Adapters

Shank adapters are critical in ensuring smooth and safe drilling operations in the mining industry. Here's why they are so important:

- Compatibility and Versatility: Shank adapters bridge the gap between various drill bits and drilling equipment. This allows for seamless integration, regardless of shank size differences. With adapters, you can utilize a wider range of drill bits without needing specific equipment for each size.

- Optimized Performance: Shank adapters ensure a secure and proper connection between the drill bit and the drill string. This translates to efficient transfer of force and power, leading to optimal drilling performance and accurate results.

- Reduced Downtime: High-quality shank adapters are built to withstand the demanding conditions of mining operations. Their durability minimizes the need for frequent replacements and repairs, reducing downtime and keeping your drilling project on schedule.

- Enhanced Safety: A loose or incompatible connection between the drill bit and equipment can pose a significant safety risk. Shank adapters ensure a secure fit, preventing potential accidents and injuries during drilling.

Shank adapters are essential for any efficient and successful drilling operation by ensuring compatibility, optimizing performance, minimizing downtime, and enhancing safety.

Shank Adapters in Mining Industry

In the mining industry, shank adapters play a pivotal role in facilitating the use of drill bits for various applications such as exploration, rock excavation, tunneling, and more. Their ability to securely connect drill bits to drilling equipment ensures that mining operations can proceed smoothly and effectively. Whether for surface or underground mining projects, shank adapters are indispensable tools that contribute to overall productivity and success.

Shank adapters are designed to withstand the harsh conditions of mining operations, ensuring durability and reliability in the most challenging environments. Their robust construction and precision engineering make them essential components for maximizing the performance and longevity of drill bits, ultimately reducing downtime and maintenance costs. By adapting to different drilling equipment, shank adapters offer versatility and flexibility for various mining applications, making them indispensable tools for achieving operational efficiency.

What are Shank Adapters?

Definition and Function of Shank Adapters

Shank adapters are crucial components that connect drill bits to drilling equipment, allowing for efficient and effective drilling operations. These adapters serve as the interface between the drill and bits, ensuring a secure connection for optimal performance in various drilling applications.

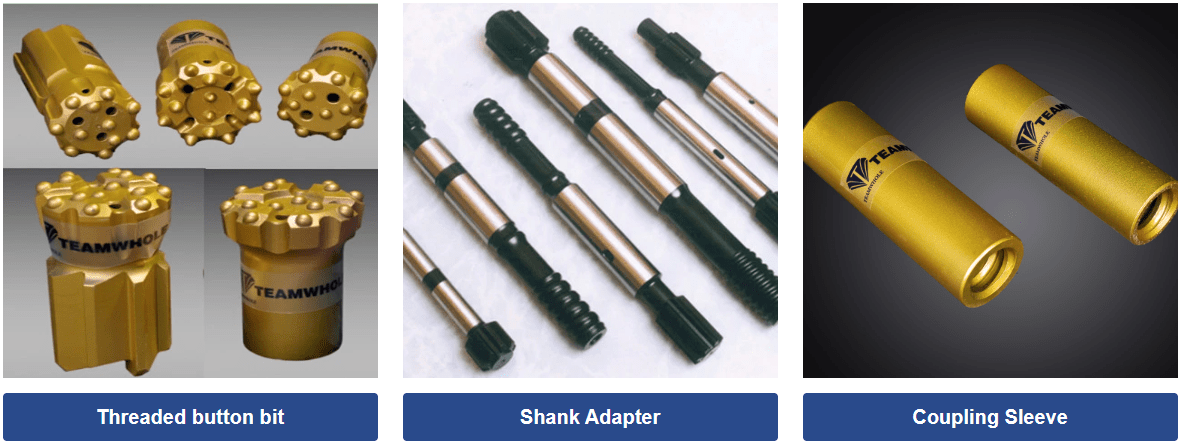

Shank adapters come in various types, including R32, R38, T38, and T45, each designed to fit specific drill rigs and equipment. These adapters are made from high-quality materials such as hardened steel to withstand the rigors of drilling in demanding conditions. Additionally, some shank adapters feature advanced designs to minimize energy loss during drilling, ultimately improving efficiency and reducing operational costs.

Types of Shank Adapters

Shank adapters are critical components that connect drill bits to drilling machines. They ensure proper fit and transfer power from the machine to the bit. Here's a breakdown of the different types available:

- R-Series Shank Adapters (R32, R38): These are commonly used for medium-duty drilling applications in mining and construction. Their design is well-suited for handling moderate impact and rotational forces.

- T-Series Shank Adapters (T38, T45, T51): Offering greater strength and durability than R-series adapters, T-series adapters are ideal for heavy-duty drilling tasks in hard rock formations. They can withstand higher impact and rotational forces.

By selecting the appropriate shank adapter based on the specific drilling project, you can optimize performance and efficiency. Choosing the right size and type ensures a secure connection, maximizes power transfer, and ultimately leads to successful drilling operations.

Benefits of Using Shank Adapters

Shank adapters are a simple yet powerful tool that can significantly improve your drilling experience. Here are some key benefits of using shank adapters:

- Enhanced Drilling Accuracy: Shank adapters ensure a secure and stable connection between the drill bit and the power tool. This reduces wobble and slippage, leading to cleaner and more precise holes.

- Reduced Drill Bit Wear: A secure connection minimizes the stress on the drill bit shank, preventing premature wear and tear. This extends the lifespan of your drill bits and saves you money on replacements.

- Improved Safety: Shank adapters prevent accidental bit ejection during operation, minimizing the risk of injury. This is especially important when working with high-powered drills.

- Increased Productivity: Shank adapters allow you to use a wider variety of drill bits with your existing power tool. This eliminates switching between multiple drills for different tasks, saving valuable time and effort.

- Quick and Easy Tool Changes: Shank adapters facilitate fast, effortless drill bit changes. This is crucial in applications requiring various drill bits for different materials or hole sizes. This flexibility minimizes downtime and keeps your project on schedule.

By incorporating shank adapters into your drilling routine, you can achieve greater accuracy, safety, and productivity. They are a cost-effective investment that can streamline your workflow and enhance the drilling experience.

Applications of Shank Adapters

Shank adapters are widely used in various industries due to their versatility and efficiency. In construction, they play a crucial role in attaching drill bits to drilling equipment, allowing for precise and efficient drilling in various projects. Whether for foundation work, tunneling, or road construction, shank adapters ensure that the right drill bits are securely attached to the drilling equipment, enabling smooth and accurate drilling operations.

1. Shank Adapters in Construction

Shank adapters are essential for connecting drill bits to drilling machines in the quarrying industry. With the right shank adapter, quarry operators can effectively carry out blasting and rock excavation processes, ensuring optimal productivity and safety at the quarry site. Whether it's for surface mining or dimensional stone quarrying, shank adapters provide the necessary connection between drill bits and drilling equipment to achieve efficient rock fragmentation and extraction.

2. Shank Adapters in Quarrying

Tianhe's advanced shank adapters are specifically designed for geotechnical drilling applications. They provide a reliable connection between drill rods and drill bits for accurate soil and rock sampling. With Tianhe's high-quality shank adapters, geotechnical drilling professionals can conduct site investigations precisely and confidently, obtaining valuable data for engineering design, environmental assessments, and construction projects.

3. Shank Adapters in Geotechnical Drilling (Tianhe)

Geotechnical drilling is essential for various construction and infrastructure projects, and using high-quality shank adapters is crucial for optimal performance. Tianhe offers a range of shank adapters specifically designed for geotechnical drilling, ensuring maximum efficiency and durability in challenging ground conditions. With Tianhe's expertise and dedication to innovation, their shank adapters are trusted by geotechnical drilling professionals worldwide for their reliability and longevity.

In addition to providing superior performance, Tianhe's shank adapters for geotechnical drilling are engineered to withstand the demands of tough drilling environments. The company's commitment to research and development ensures that its products meet the industry's evolving needs, making it a preferred choice for geotechnical drilling operations. Whether rock coring or soil sampling, Tianhe's shank adapters are designed to deliver exceptional results in geotechnical applications.

Choosing the Right Shank Adapter

When selecting the right shank adapter for your drilling needs, several factors must be considered. The type of drill and bits mining operation, the hardness of the rock or material being drilled, and the desired drilling speed all play a crucial role in determining which shank adapter best suits the job. It's important to assess these factors carefully to choose a shank adapter that will deliver optimal performance and longevity.

Factors to Consider When Selecting Shank Adapters

Selecting the right shank adapter ensures a secure connection between your drill and various drill bits. Here are some key factors to consider when choosing a shank adapter:

- Drill Bit Compatibility: Different drill bits have specific shank styles (e.g., round, hex, SDS). Choose an adapter that matches your drill bit's shank design for proper fit and functionality.

- Material Compatibility: Consider the material you'll be drilling. Harder or more abrasive materials require shank adapters from robust materials like forged steel to handle the stress.

Considering these factors, you can select a shank adapter that optimizes your drilling performance and ensures a safe and efficient workflow.

Compatibility with Drill Bits

Compatibility with drill bits is a critical consideration when choosing a shank adapter. The shank adapter must be compatible with the size and design of the drill bits for optimal performance. A secure fit between the shank adapter and drill bit prevents slippage during operation, which can lead to reduced drilling efficiency and potential damage to both components.

Tianhe's Recommendation for Shank Adapters

With years of expertise in manufacturing high-quality drilling tools, Tianhe recommends choosing shank adapters for heavy-duty mining applications. Their range of premium shank adapters is engineered to withstand tough drilling conditions while delivering exceptional performance and durability. By selecting Tianhe's recommended shank adapters, you can be confident in achieving efficient and reliable results in your mining operations.

Maintenance and Care of Shank Adapters

Proper Handling and Storage

Proper handling and storage of shank adapters are crucial to ensuring their longevity and performance. When handling shank adapters, avoid dropping or mishandling them to prevent potential damage. Additionally, storing them in a clean, dry environment away from corrosive materials or extreme temperatures will help maintain their integrity and effectiveness.

Inspection and Replacement of Worn Shank Adapters

Shank adapters must be regularly inspected to identify any signs of wear or damage. This can include checking for cracks, excessive wear on the threads, or any deformation that could affect their performance. If any issues are found during the inspection, it's crucial to replace the worn shank adapters promptly to prevent potential safety hazards or operational inefficiencies.

Tianhe's Tips for Prolonging Shank Adapter Lifespan

Tianhe recommends a proactive maintenance schedule for shank adapters to prolong their lifespan. This includes following proper handling and storage practices, conducting regular inspections, and promptly replacing worn adapters when necessary. Additionally, utilizing high-quality drill bits designed for compatibility with shank adapters can help minimize wear and tear, ultimately extending their lifespan.

Advancements in Shank Adapter Technology

In recent years, significant innovations in shank adapter design have revolutionized the drilling industry. Manufacturers like Tianhe have introduced new materials and manufacturing techniques to create shank adapters that are lighter, stronger, and more resistant to wear and tear.

Innovations in Shank Adapter Design

One of the most notable innovations in shank adapter design is using advanced alloys and heat treatment processes. This has resulted in shank adapters that are more durable and can withstand the extreme conditions of mining and construction sites. Additionally, new designs have improved the flushing ability of shank adapters, allowing for better chip removal during drilling operations.

Enhanced Performance and Durability

The advancements in shank adapter technology have led to enhanced performance and durability. With these new designs, drill bits can be securely attached to the shank adapters, minimizing the risk of breakage or slippage during operation. This has significantly increased productivity and reduced downtime for maintenance.

Tianhe's Contribution to Shank Adapter Development

Tianhe has been at the forefront of shank adapter development, continuously investing in research and development to improve its products. Their commitment to innovation has resulted in shank adapters that offer superior performance, longevity, and compatibility with a wide range of drill bits.

With these technological advancements, choosing the right shank adapter is crucial for maximizing efficiency and achieving optimal drilling operations results. As manufacturers continue to push boundaries with new designs and materials, the future of shank adapters is bright.

Investing in quality shank adapters will improve productivity and reduce overall costs by minimizing downtime due to equipment failure or maintenance issues. With Tianhe leading the way in innovation, it's clear that their contributions will continue to shape the future of drilling technology for years to come.

Tianhe's Role in Advancing Shank Adapter Technology

When it comes to maximizing efficiency with shank adapters, the key lies in investing in quality products that are designed to withstand the rigors of heavy-duty applications like bits mining. Tianhe has been pivotal in advancing shank adapter technology, ensuring that drill and bits work seamlessly together to deliver optimal results. By choosing the right drill bits for drill and investing in top-notch shank adapters, you can ensure that your operations run smoothly and efficiently.

Maximizing Efficiency with Shank Adapters

Using high-quality shank adapters is essential for maximizing efficiency in drilling operations. You can ensure smooth drilling processes and minimize downtime with the right combination of shank adapters and drill bits. By investing in top-notch shank adapters, you can significantly improve the performance of your equipment and achieve better results in less time.

Tianhe has been advancing shank adapter technology, constantly innovating to enhance performance and durability. Their commitment to developing cutting-edge solutions for drill and drill bits has revolutionized the industry, making them a trusted partner for businesses looking to optimize their drilling operations.

Investing in Quality Shank Adapters for Optimal Results

When achieving optimal results in drilling operations, investing in quality shank adapters is non-negotiable. The right combination of drill bits for drill and high-performance shank adapters can make all the difference in productivity and cost-effectiveness. By choosing top-notch products from reputable manufacturers like Tianhe, you can ensure that your drilling operations are set up for success.