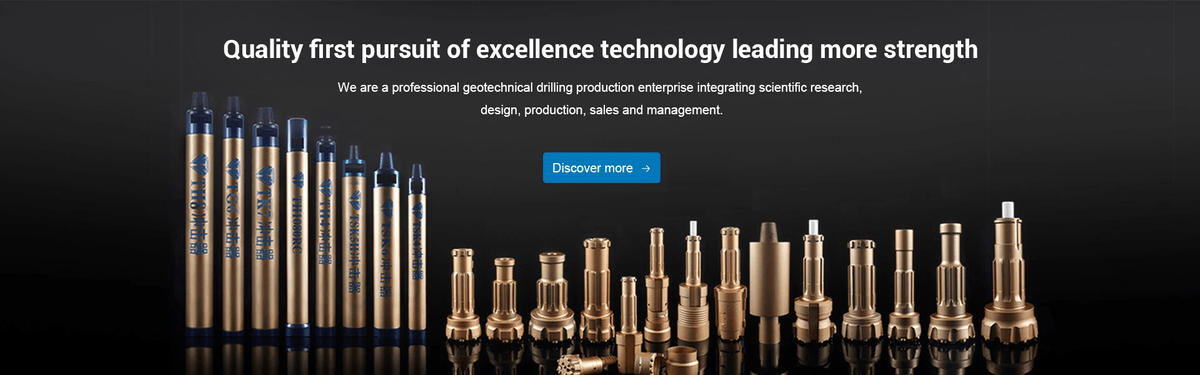

Introduction

When it comes to geotechnical drilling, selecting the right DTH hammer bit is crucial for achieving optimal results. Whether you're drilling with a bit for construction, mining, or exploration, choosing the right drill and bits can make all the difference in the success of your project. At Tianhe, we understand the importance of DTH hammer bit selection and are here to provide expert guidance and solutions for your drilling needs.

Understanding DTH Hammer Bit Selection

Selecting the right DTH hammer bit involves considering various factors such as rock formation, drilling diameter, and operating pressure. With a wide range of options available, understanding the specific requirements of your project is essential for choosing the most suitable drill bits for drill success.

After considering the rock formation, drilling diameter, and operating pressure, it's important also to consider the type of material the DTH hammer bit is made of. Different materials offer different levels of durability and performance, so selecting the right material can greatly impact the success of your drilling project. Factors such as carbide composition and steel quality should be carefully evaluated to ensure optimal performance and longevity of the drill bit.

Key Factors for Choosing the Right Drill Bit

Selecting the right drill bit is essential for efficient and successful drilling operations. Here are the crucial factors to consider:

1. Material and Rock Properties

- Rock Hardness and Abrasiveness: Harder rocks require more robust drill bits. Abrasive materials can quickly wear down bits, so choosing a bit with the appropriate hardness is crucial.

2. Bit Design

- Matching Design to Formation: Different rock formations necessitate specific bit designs. For instance, chisel bits are suitable for hard rock, while drag bits are better suited for softer formations.

3. Bit Size

- Selecting the Correct Diameter: The drill bit diameter should slightly exceed the anchor or fastener. Choosing the right size ensures a secure fit and prevents damage to the material.

4. Drilling Environment

- Temperature, Pressure, and Fluids: Extreme temperatures, pressure, and water or other fluids can affect the bit's performance. Selecting a bit designed to withstand these conditions optimizes drilling efficiency and lifespan.

By carefully considering these factors, you can choose the most appropriate drill bit for your specific application, ensuring optimal drilling performance and cost-effectiveness.

Tianhe: Your Expert in Geotechnical Drilling

At Tianhe, we pride ourselves on being experts in geotechnical drilling solutions. With our extensive knowledge and experience in DTH hammer bits and drilling equipment, we are committed to providing our customers with top-quality products and expert guidance to ensure successful outcomes for their projects.

As an industry leader, we understand the importance of staying ahead of the curve when it comes to drilling technology. That's why we continuously invest in research and development to bring our customers the latest DTH hammer bits and drilling equipment advancements. By partnering with Tianhe, you can confidently utilize the most innovative and efficient tools for your geotechnical drilling projects.

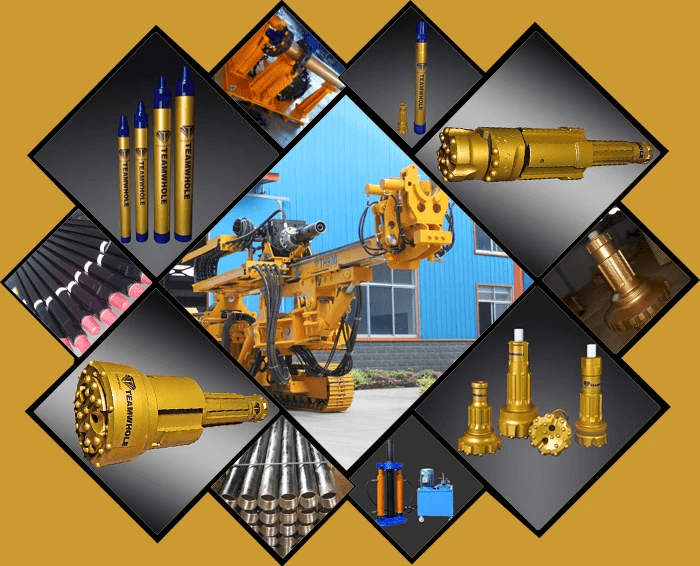

Types of DTH Hammer Bits

When it comes to geotechnical drilling, choosing the right type of DTH hammer bit is crucial for achieving optimal results. One popular option is the button bit, which features spherical buttons with excellent impact resistance and penetration rates. These bits are ideal for drilling in medium to hard rock formations, making them versatile for various projects.

1. Button Bits

Button bits are designed with multiple buttons on the face of the bit, providing efficient energy transfer and rock-breaking capabilities. The buttons are strategically placed to ensure even wear and extended bit life, making them a cost-effective option for long-term use. With Tianhe's expertise in geotechnical drilling, you can trust that button bits will deliver superior performance in challenging drilling conditions.

2. DTH Hammer Bits with Symmetric Air Holes

Another type of DTH hammer bit is equipped with symmetric air holes, allowing for efficient air distribution and cooling during drilling operations. These bits are suitable for abrasive rock formations and offer enhanced stability and precision during drilling. With Tianhe's advanced technology and engineering, these bits are designed to withstand high-impact forces while maintaining consistent performance.

3. DTH Hammer Bits with Concentric Air Holes

DTH hammer bits with concentric air holes are engineered for optimal energy transfer and hole cleaning capabilities. The design efficiently removes cuttings from the borehole while maintaining stable penetration rates in varying rock formations. Tianhe's commitment to innovation ensures that these bits deliver reliable performance and longevity, making them a valuable asset for geotechnical drilling projects.

Considering the various types of DTH hammer bits available, assessing your specific drilling requirements is essential to determine the most suitable option for your project. Whether you're facing hard or abrasive rock formations, a perfect drill bit match is waiting for you at Tianhe.

Factors to Consider in DTH Hammer Bit Selection

When selecting the right DTH hammer bit for your drilling project, it is crucial to consider the rock hardness and abrasiveness of the formation you'll be drilling into. Different bit designs and materials are better suited for varying rock types, so understanding the geology of your drilling site is essential for the optimal performance and longevity of the bit.

1. Rock Hardness and Abrasiveness

The hardness and abrasiveness of the rock formation directly impact the wear and tear on your DTH hammer bit. For softer formations, a button bit with tungsten carbide buttons may be more suitable, while harder formations may require a diamond-enhanced design for increased durability. Understanding these factors will help you choose a bit that can withstand the specific challenges of different rock types.

2. Drilling Diameter and Depth

Another key factor to consider is the diameter and depth of your drilling project. Different drill bits are designed for specific hole sizes and depths, so selecting a bit that matches your project requirements is important. Choosing the right size will optimize drilling efficiency and prevent unnecessary wear on the bit due to overworking or underutilization.

3. Operating Pressure and Air Flow

Your drilling equipment's operating pressure and air flow also play a significant role in DTH hammer bit selection. Different bits are designed to perform optimally within certain pressure ranges, so ensuring that your equipment's capabilities align with your chosen bit is crucial for achieving efficient drilling operations.

Now that we've covered the key factors to consider in DTH hammer bit selection, it's clear that understanding rock hardness, matching drill diameter and depth, and optimizing operating pressure are essential for choosing the right tool for any geotechnical drilling project. With Tianhe as your trusted partner in geotechnical drilling solutions, mastering these factors will lead to superior results in every operation!

Choosing the Right DTH Hammer Bit for Your Project

When it comes to matching bit design to rock formation, it's crucial to consider the specific geological conditions of your drilling site. Different rock formations require different bit designs to maximize drilling efficiency and minimize wear and tear on your equipment. Tianhe offers a wide range of DTH hammer bits designed for various rock formations, ensuring you can find the perfect match for your project.

Selecting the correct bit size is essential for achieving optimal drilling performance. Using a bit that is too small can result in slow progress and increased wear on the bit while using a bit that is too large can lead to inefficient drilling and unnecessary strain on your equipment. Tianhe's expert team can help you determine the ideal bit size for your drilling needs, ensuring maximum productivity with minimal downtime.

When optimizing performance and cost efficiency, Tianhe's DTH hammer bits are designed to deliver exceptional results while maximizing longevity and minimizing maintenance costs. By selecting the right bit design and size for your project, you can achieve superior drilling performance without overspending on unnecessary equipment or maintenance expenses.

Tianhe's DTH hammer bits are also engineered with advanced materials and precision manufacturing techniques to enhance durability and minimize wear and tear during drilling operations. This means less frequent replacement of bits, leading to reduced downtime and increased productivity for your project.

Maintenance and Longevity of DTH Hammer Bits

1. Proper Cleaning and Storage

Proper cleaning and storage are essential to ensure the longevity of your DTH hammer bit. After each use, thoroughly clean the bit to remove any debris or buildup that could affect its performance. Store the bit in a dry, secure location to prevent damage or corrosion.

2. Regular Inspection and Repair

Regular inspection and repair of your DTH hammer bit are crucial for maintaining its effectiveness. Inspect the bit for any signs of wear or damage and address any issues promptly to prevent further deterioration. By staying on top of maintenance, you can extend the lifespan of your drill bit and avoid costly replacements.

Regular inspection and repair of your DTH hammer bit are crucial for maintaining its effectiveness. Inspect the bit for any signs of wear or damage and address any issues promptly to prevent further deterioration. By staying on top of maintenance, you can extend the lifespan of your drill bit and avoid costly replacements. Additionally, keeping a detailed maintenance log can help you track the performance of your DTH hammer bit over time, allowing you to anticipate when it may need servicing or replacement. This proactive approach can save you time and money in the long run by preventing unexpected downtime due to equipment failure.

3. Extending Bit Lifespan with Tianhe's Expert Tips

Tianhe offers expert tips for extending the lifespan of your DTH hammer bits. From proper drilling techniques to optimizing air flow, their guidance can help maximize performance and minimize wear on your drill bits. By following their recommendations, you can achieve superior results while getting the most out of your investment.

Now that you have a better understanding of how to maintain and extend the longevity of your DTH hammer bits, you can ensure that they continue to deliver optimal performance for your drilling projects. With Tianhe's expert guidance, you'll be well-equipped to tackle geotechnical drilling with confidence and efficiency.

Achieve Optimal Drilling Efficiency with the Right DTH Hammer Bit

Nothing beats the importance of choosing the right DTH hammer bit when achieving optimal drilling efficiency. With the right bit, you can ensure smoother drilling operations, reduce wear and tear on your equipment, and save time and money. Tianhe is your trusted partner in geotechnical drilling solutions, offering expert guidance in DTH hammer bit selection to ensure superior results for your projects. Mastering the art of DTH hammer bit selection is key to unlocking superior drilling performance, and Tianhe is here to help you every step.

Choosing the right DTH hammer bit is crucial for achieving optimal drilling efficiency. With a carefully selected drill bit, you can minimize downtime, increase productivity, and reduce overall drilling costs. By understanding your project's specific requirements and selecting the appropriate DTH hammer bit, you can ensure that each drilling operation runs smoothly and effectively.

Tianhe: Your Trusted Partner in Geotechnical Drilling Solutions

Tianhe is more than just a drill bit supplier —we are your trusted partner in geotechnical drilling solutions. With our expertise and industry knowledge, we provide comprehensive support in selecting the right DTH hammer bits for your specific needs. From initial consultation to ongoing maintenance, we are committed to ensuring that you have access to top-quality drill bits that deliver exceptional performance.

Mastering DTH Hammer Bit Selection for Superior Results

Mastering DTH hammer bit selection is essential for achieving superior results in geotechnical drilling projects. By understanding the key factors influencing drill bit performance and longevity, you can make informed decisions that optimize efficiency and cost-effectiveness. With Tianhe's expert guidance, you can master the art of selecting the perfect DTH hammer bit for every project, ensuring superior results every time.

Once you have mastered the art of selecting the perfect DTH hammer bit for your geotechnical drilling projects, you can consistently achieve superior results. This level of expertise will optimize efficiency and cost-effectiveness and enhance your reputation as a skilled and knowledgeable professional in the industry. With Tianhe's expert guidance, you can stay ahead of the competition and ensure that every drilling project is completed with precision and excellence.