Introduction

When it comes to drilling, down-the-hole (DTH) piling is a game-changer. This innovative method involves using a hammer to drill through rock formations, making it ideal for mining and construction projects. But what sets the fastest DTH hammer apart from the rest? And what about the smallest down the hole hammer? Let's dive in and explore these groundbreaking tools that are revolutionizing the drilling industry.

What is down-the-hole piling?

Down-the-hole (DTH) piling is a cutting-edge drilling technique that involves using a hammer to pound a drill bit into the rock formation. This method allows for deeper and more precise drilling, making it perfect for various applications such as mining, water well drilling, and foundation construction.

What is the fastest DTH hammer?

When it comes to speed and efficiency, the fastest DTH hammers are unmatched in their ability to penetrate even the toughest rock formations with lightning-fast precision. These powerful tools are essential for maximizing productivity in challenging drilling conditions.

What is the smallest down the hole hammer?

On the other end of the spectrum, we have the smallest down the hole hammers that pack a punch despite their compact size. These miniature marvels offer versatility and maneuverability, making them ideal for tight spaces and intricate drilling projects. Their small size also means they are easier to transport to remote or hard-to-reach locations, allowing for drilling in areas that larger equipment simply cannot access. Additionally, their lightweight design reduces operator fatigue, making them a practical choice for extended drilling operations in challenging environments.

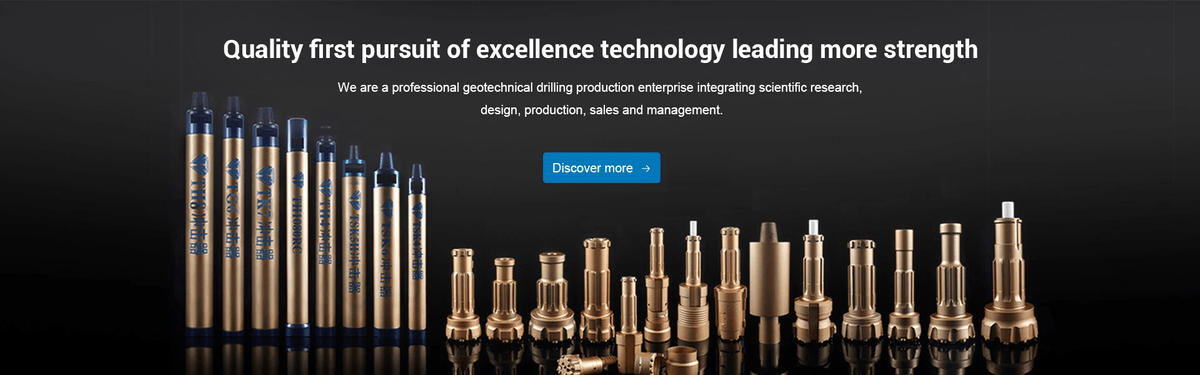

TEAMWHOLE - A Leader in DTH Hammers

When it comes to down-the-hole piling, TEAMWHOLE is a top contender in the market. Their DTH hammers offer superior efficiency for mining, water well drilling, and foundation construction. With their cost-effective alternative to casing drilling tools, TEAMWHOLE provides a reliable solution for various drilling needs. Additionally, their DTH hammers can reach single hole depths over 25m, making them a versatile choice for deep drilling projects.

Superior efficiency for mining, water well drilling, and foundation construction

TEAMWHOLE's down the hole hammers are renowned for their superior efficiency across different industries. Whether it's mining operations or water well drilling, their DTH hammers deliver exceptional performance and reliability. With advanced technology and precision engineering, TEAMWHOLE ensures optimal drilling results for their clients.

In addition to their exceptional performance in mining and water well drilling, TEAMWHOLE's down the hole hammers also provide a cost-effective alternative to casing drilling tools. By offering a more efficient and economical solution, TEAMWHOLE helps their clients save on operational costs without compromising on quality or performance. This makes their DTH hammers a smart choice for companies looking to maximize their drilling efficiency while staying within budget.

Cost-effective alternative to casing drilling tools

In comparison to traditional casing drilling tools, TEAMWHOLE's DTH hammers offer a cost-effective alternative without compromising on quality or performance. This makes them an attractive option for companies looking to maximize productivity while staying within budget constraints.

In addition to being cost-effective, TEAMWHOLE's DTH hammers also offer the advantage of single hole depths over 25m. This means that companies can achieve deeper drilling without having to invest in more expensive equipment. As a result, they can maximize their productivity and efficiency without exceeding their budget constraints. This makes TEAMWHOLE's DTH hammers a practical and economical choice for companies in need of reliable casing drilling tools.

Single hole depths over 25m

One of the standout features of TEAMWHOLE's DTH hammers is their capability to reach single hole depths over 25m. This impressive depth capacity makes them suitable for a wide range of applications where deep drilling is required.

Top Performance with SANDVIK

SANDVIK DTH hammers offer exceptional drilling through complex rock formations, making them the top choice for challenging projects. With their high penetration rates in hard rocks, SANDVIK hammers ensure efficient and effective drilling, saving time and resources. What's more, their low air consumption makes them a cost-effective and environmentally friendly option for down-the-hole piling.

Exceptional drilling through complex rock formations

SANDVIK DTH hammers excel in drilling through complex rock formations, providing reliable performance even in the most challenging geological conditions. Their precision engineering and advanced technology make them a top performer in the industry, delivering optimal results for demanding projects.

High penetration rates in hard rocks

When it comes to hard rocks, SANDVIK DTH hammers stand out with their impressive high penetration rates. This allows for faster progress and increased productivity, making them the go-to choice for projects that require efficient drilling through tough surfaces.

Low air consumption

In addition to their exceptional drilling capabilities, SANDVIK DTH hammers boast low air consumption, contributing to cost savings and reduced environmental impact. With this feature, they provide a sustainable solution without compromising on performance or reliability.

Efficiency and Reliability with ATLAS COPCO

Atlas Copco is a renowned manufacturer of down-the-hole hammers, offering a simple yet robust structure that ensures high reliability and easy maintenance. This means less downtime for repairs and more time for productive drilling, making it an ideal choice for any drilling project.

Simple structure for high reliability and easy maintenance

The Atlas Copco DTH hammer boasts a straightforward design that minimizes the risk of malfunctions, ensuring consistent performance in even the most challenging drilling conditions. This simplicity also translates to easier maintenance, reducing overall operational costs and maximizing efficiency.

Customized DTH bit steel reduces body breakage and cracking failure

One of the key features of Atlas Copco's DTH hammers is their customized bit steel, which is specifically engineered to minimize body breakage and cracking failure. This enhances the durability and longevity of the hammer, providing reliable performance over extended periods of heavy use.

Easy modification with fixed stabilizer position

Atlas Copco's DTH hammers offer the flexibility to modify the fixed stabilizer position according to specific drilling requirements, allowing for precise control and adaptability in various geological formations. This customization ensures optimal drilling results while maintaining stability and efficiency throughout the process.

In addition to the flexibility in modifying the fixed stabilizer position, Atlas Copco's DTH hammers also boast advanced technology that allows for real-time monitoring and adjustment of drilling parameters. This feature enables operators to make on-the-fly changes to the drilling process, ensuring maximum productivity and efficiency even in challenging geological conditions. With this level of control and adaptability, Atlas Copco's DTH hammers are a top choice for contractors looking to optimize their drilling operations.

Versatility with NUMA

NUMA offers a versatile solution for various drilling needs, making it a top choice for professionals in the industry. Whether it's mining, water well drilling, or foundation construction, NUMA down hole hammers deliver exceptional performance and reliability. With its innovative design and advanced technology, NUMA ensures superior results in any drilling project.

Versatile solution for various drilling needs

NUMA down hole hammers are designed to cater to a wide range of drilling needs, from soft soil to hard rock formations. This versatility makes it an ideal choice for contractors and operators who require flexibility in their operations. With NUMA's down-the-hole hammers, you can tackle different types of projects without the need for multiple equipment setups.

With NUMA's down-the-hole hammers, you can achieve maximum productivity even in challenging drilling conditions. Whether you're dealing with abrasive formations or encountering unexpected obstacles underground, these hammers are built to deliver consistent performance and efficiency. This reliability allows contractors and operators to stay on schedule and within budget, no matter the difficulties they may face during drilling operations.

Maximum productivity in challenging conditions

When faced with challenging drilling conditions, NUMA down hole hammers rise to the occasion by delivering maximum productivity. Whether it's rocky terrain or tough soil, these hammers are built to handle the toughest of conditions with ease. Their high penetration rates and efficient operation ensure that projects are completed on time and within budget.

NUMA down hole hammers are designed with innovative features that contribute to their superior performance in challenging drilling conditions. The use of advanced materials and cutting-edge technology ensures that these hammers can withstand the rigors of demanding environments, providing reliable and consistent operation. Their innovative design allows for optimal energy transfer, resulting in maximum impact and penetration, making them the go-to choice for projects where productivity is paramount.

Innovative design for superior performance

NUMA's down hole hammers boast an innovative design that sets them apart from the competition. Their advanced engineering and precision manufacturing result in superior performance and durability. With NUMA's focus on innovation, you can trust that their down-the-hole hammers will consistently deliver exceptional results across various drilling applications.

Quality Craftsmanship with HALCO

When it comes to durable and reliable DTH hammers, HALCO is a top choice for quality craftsmanship. Their hammers are built to withstand the toughest drilling conditions, ensuring long-lasting performance and reliability in the field. With precision engineering at the core of their design, HALCO hammers deliver optimal drilling results, making them a trusted choice for professionals in the industry. Additionally, their advanced technology maximizes efficiency, allowing for seamless operation and enhanced productivity on the job site.

Durable and reliable DTH hammers

HALCO's DTH hammers are known for their durability and reliability, making them a go-to option for professionals in need of long-lasting equipment that can withstand rigorous drilling operations. With a focus on quality craftsmanship, HALCO ensures that their hammers can endure the most challenging drilling conditions while delivering consistent performance over time.

HALCO's commitment to precision engineering ensures that their DTH hammers deliver optimal drilling results, making them a top choice for professionals seeking efficiency and accuracy in their drilling operations. By incorporating advanced design and manufacturing techniques, HALCO hammers are able to consistently produce precise boreholes with minimal deviation, saving time and resources for their users. This attention to detail sets HALCO apart in the industry, providing a reliable solution for achieving high-quality drilling outcomes.

Precision engineering for optimal drilling results

HALCO's commitment to precision engineering sets their DTH hammers apart, providing operators with the assurance of optimal drilling results every time. By meticulously designing and crafting their equipment to exacting standards, HALCO ensures that their hammers deliver superior performance and accuracy in various drilling applications.

HALCO's dedication to precision engineering extends beyond just the design and crafting of their DTH hammers. They also integrate advanced technology into their equipment to maximize drilling efficiency. This combination of meticulous engineering and cutting-edge technology ensures that operators can achieve optimal results in a wide range of drilling applications, from mining to construction.

Advanced technology for maximum efficiency

Equipped with advanced technology, HALCO's DTH hammers offer maximum efficiency on the job site. From innovative design features to cutting-edge components, these hammers are engineered to streamline drilling operations and enhance overall productivity. With HALCO's focus on technological advancements, operators can rely on their equipment to meet the demands of challenging projects while maintaining peak efficiency.

Furthermore, HALCO's DTH hammers are designed with durability in mind, ensuring that they can withstand the rigors of heavy-duty drilling operations. The use of high-quality materials and precision engineering means that these hammers are built to last, reducing downtime for maintenance and repairs. This reliability allows operators to focus on their work with confidence, knowing that their equipment will perform consistently.

Conclusion

When it comes to drilling, the difference between rotary and DTH lies in the method of power transmission, with DTH using a hammering action to break through rock formations. Odex, on the other hand, stands for Overburden Drilling System and is a casing system used in drilling through unstable ground conditions. For those in need of Down the Hole (DTH) Hammers or a wholesale mini down the hole hammer drill rig, look no further than Teamwhole for top-notch quality and efficiency.

What is the difference between rotary and DTH?

Rotary drilling involves a continuous rotation of the drill string to create boreholes, while DTH piling utilizes a hammering action to break through hard rock formations. The latter is often preferred for its ability to penetrate challenging ground conditions with greater ease and efficiency.

What does Odex stand for in drilling?

Odex stands for Overburden Drilling System and is specifically designed for drilling through unstable ground conditions such as sand, gravel, and boulders. It provides casing support during drilling operations, preventing cave-ins and maintaining borehole stability.

Down the Hole (DTH) Hammers, Wholesale mini down the hole hammer drill rig

For top-quality Down the Hole (DTH) Hammers or a wholesale mini down the hole hammer drill rig, Teamwhole offers superior efficiency and reliability for various drilling needs. With their advanced technology and precision engineering, you can expect maximum productivity and optimal results in your drilling operations.