Introduction

When it comes to construction and drilling projects, the pneumatic hammer drill is an essential tool that offers power and precision. However, using this powerful tool safely is of utmost importance to prevent accidents and injuries on the job site. In addition to safety, understanding the benefits of effective pneumatic hammer drill usage can lead to improved efficiency and productivity. Moreover, choosing the right drill bit is crucial for achieving success in any drilling project, making it a key factor in the overall operation.

Importance of Using Pneumatic Hammer Drill Safely

Using a pneumatic hammer drill safely is crucial due to several key reasons that impact both the operator and the environment around them. A pneumatic hammer drill is a powerful tool that uses compressed air to drill or break into hard materials like concrete, stone, and metal. The importance of using this tool safely can be outlined as follows:

1. Prevention of Accidents and Injuries

The most immediate reason for emphasizing safety is to prevent accidents and injuries. Incorrect usage or negligence can lead to severe injuries, including cuts, bruises, or more serious harm like fractures or concussions. Ensuring proper handling and safety measures can significantly reduce the risk of such incidents.

2. Protection of Hearing and Vibration-Related Health Issues

Pneumatic hammer drills generate significant noise and vibrations, which can lead to hearing loss or conditions such as Hand-Arm Vibration Syndrome (HAVS) if proper precautions are not taken. Using personal protective equipment (PPE) like ear protection and anti-vibration gloves can mitigate these risks.

3. Longevity and Maintenance of the Tool

Using the tool safely includes following the manufacturer's guidelines for operation and maintenance. This not only ensures the safety of the operator but also prolongs the life of the tool, ensuring it remains efficient and reliable over time.

4. Efficiency and Productivity

Safe use of a pneumatic hammer drill also means using it correctly and efficiently. This ensures that the job is done effectively, with minimal waste of time and resources. Knowing how to use the tool properly can also prevent damage to the material being worked on.

5. Legal and Compliance Reasons

There are often legal requirements and safety standards that must be adhered to when using industrial equipment like pneumatic hammer drills. Failure to comply with these regulations can result in fines, legal action, or both. Ensuring safety is also a part of fulfilling workplace health and safety obligations.

6. Environmental Considerations

Safe use includes being mindful of the surrounding environment. This means preventing unnecessary pollution, noise, and damage to surrounding areas or structures, which is part of responsible and sustainable work practices.

Benefits of Effective Pneumatic Hammer Drill Usage

Effective usage of a pneumatic hammer drill, beyond ensuring safety, brings a multitude of benefits that enhance productivity, work quality, and overall efficiency in construction, renovation, and demolition projects. Here are some key benefits of utilizing a pneumatic hammer drill effectively:

1. Increased Efficiency and Productivity

Pneumatic hammer drills are designed for high performance in drilling through or demolishing hard materials like concrete, brick, and stone. When used effectively, these tools can significantly speed up work processes, allowing for faster completion of tasks compared to manual methods or less powerful tools.

2. Precision and Control

Modern pneumatic hammer drills are equipped with features that offer greater control and precision. This precision ensures that work is not only done more quickly but also with a higher degree of accuracy, reducing the likelihood of mistakes that could waste materials or require time-consuming corrections.

3. Versatility

Effective use of pneumatic hammer drills often involves utilizing different bits and attachments that can be suited to various tasks, from drilling precise holes to chipping away at concrete or even cutting through metal. This versatility makes the pneumatic hammer drill an invaluable tool in a wide range of construction and maintenance tasks.

4. Cost-Effectiveness

By increasing efficiency and reducing the time required to complete tasks, effective pneumatic hammer drill usage can lead to significant cost savings. These savings come from reduced labor costs, less time spent on projects, and minimized need for redoing work due to errors.

5. Reduced Physical Strain

Pneumatic hammer drills take on the bulk of the physical effort required to break through tough materials, reducing the strain on the operator. When used properly, these tools can help prevent fatigue and reduce the risk of musculoskeletal injuries, which are common in manual labor.

6. Enhanced Durability and Tool Life

Effective use also means adhering to operational guidelines and performing regular maintenance. This not only ensures the safety and productivity mentioned but also enhances the tool's durability, ensuring it remains in good working condition for a longer period, thus offering a better return on investment.

7. Environmental Considerations

Efficient use of pneumatic hammer drills can also contribute to environmental sustainability. By reducing the time and energy required for tasks, these tools can help lower the carbon footprint of construction projects. Additionally, precise and efficient work reduces waste materials, further contributing to environmental benefits.

Choosing the Right Drill Bit: The Key to Success

The selection of the right drill bit plays a critical role in achieving successful drilling operations. Different materials and surfaces require specific types of bits for optimal results. Understanding these requirements and choosing the appropriate Tianhe's DTH rock drill bits can make all the difference in the outcome of a project.

Understanding Your Pneumatic Hammer Drill

When it comes to understanding your pneumatic hammer drill, it's essential to familiarize yourself with its features and functions. A pneumatic hammer drill, also known as an air hammer drill or rock hammer drill, is a powerful tool that uses compressed air to create rapid, repetitive hammering motions.

This makes it ideal for drilling through tough materials like rock and concrete. Understanding the various settings and modes of your pneumatic rotary hammer drill will allow you to maximize its efficiency and performance.

Knowing the Features and Functions

The features of a pneumatic hammer drill can vary depending on the model, but most will include adjustable speed settings, a forward/reverse switch, and a depth gauge for precise drilling. Some models may also come with additional features, such as vibration reduction technology or dust extraction systems. Understanding how each feature works will enable you to tailor the tool to different drilling tasks and ensure optimal results.

Proper Handling and Maintenance

Proper handling of your pneumatic rock drill is crucial for both safety and longevity. Always ensure that you have a firm grip on the tool during operation, and never force it into the material being drilled. Regular maintenance, such as cleaning the air intake vents and lubricating moving parts, is essential for keeping your pneumatic hammer drill in top condition. Following the manufacturer's guidelines for maintenance will help prevent malfunctions and extend the lifespan of your tool.

Importance of Regular Inspections

Regular inspections of your pneumatic hammer drill are vital for identifying any potential issues before they escalate into major problems. Check for signs of wear on the chuck, inspect the cord or hose for any damage, and listen for any unusual sounds during operation. Addressing these issues promptly can prevent accidents and costly repairs down the line.

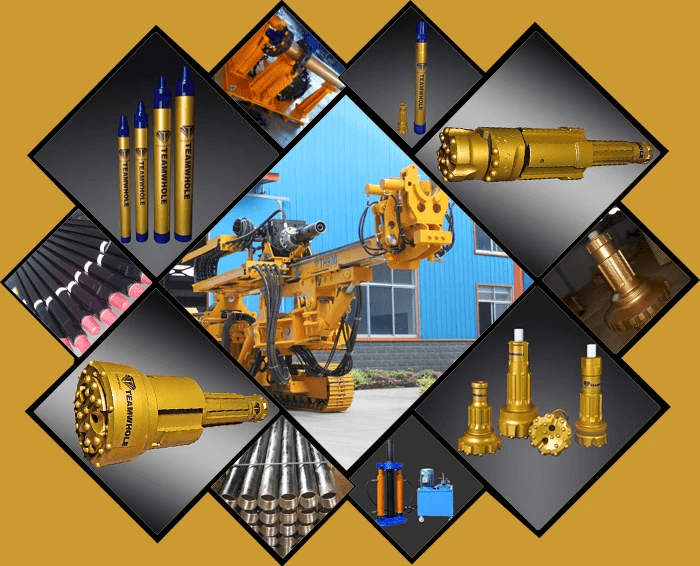

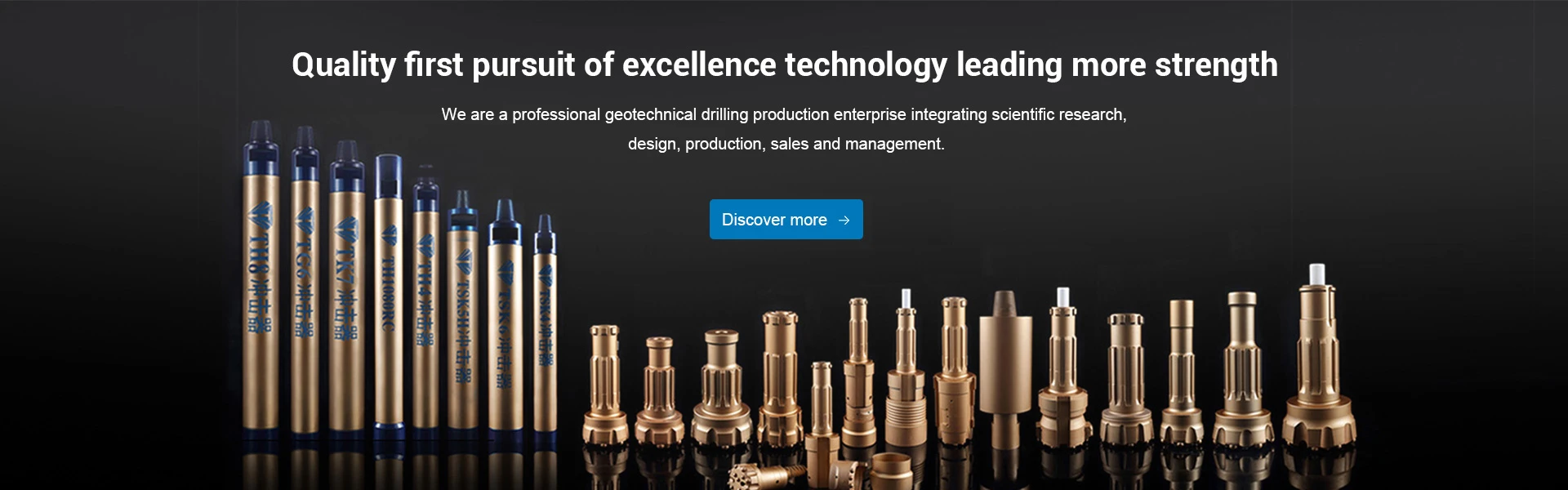

As a professional geotechnical drilling manufacturer in research, design, production, sales, and management, Tianhe understands the importance of proper understanding of pneumatic rock drills like no other!

Selecting the Right Drill Bit

When it comes to selecting the right drill bit for your pneumatic hammer drill, it's essential to understand the different types available. From pneumatic rock drill bits to hammer drills for rock, there are specific bits designed for various materials and applications. Understanding the differences will ensure that you choose the best bit for your project, leading to more efficient and effective drilling.

Understanding Different Types of Bits

Pneumatic hammer drills can be used for a variety of drilling tasks, from concrete and masonry to metal and wood. Each type of material requires a specific type of drill bit, such as a rock drill hammer for hard surfaces or an air hammer drill for softer materials. By familiarizing yourself with the different types of bits available, you can make informed decisions about which one is best suited for your needs.

Quality Matters: The Role of Tianhe's DTH Drill Bit

When it comes to quality pneumatic rock drill bits, Tianhe stands out as a professional geotechnical drilling manufacturer known for its research, design, production, sales, and management expertise. Their Down-The-Hole (DTH) drill bits are engineered with precision and durability in mind, ensuring high performance and longevity in demanding drilling applications. Choosing a high-quality bit like Tianhe's DTH drill bit can make all the difference in achieving successful drilling results.

Tips for Proper Bit Selection

To ensure proper bit selection for your pneumatic hammer drill, consider factors such as:

- the material you'll be drilling into

- the depth required

- the speed at which you'll be working

It's also important to match the shank size of the bit with your specific hammer drill model to guarantee compatibility and optimal performance. Consulting with experts or referring to manufacturer guidelines can provide valuable insights into choosing the right bit for your drilling needs.

With these tips in mind, you can confidently select the right pneumatic rock drill bits or hammer drills for rock that will deliver exceptional results while using your pneumatic hammer drill safely and effectively throughout your projects.

Safety Precautions and Best Practices

When using a pneumatic hammer drill, it is crucial to prioritize safety at all times. Wearing proper personal protective equipment (PPE) such as safety goggles, ear protection, and a dust mask is essential to prevent injuries and exposure to harmful particles. Additionally, wearing sturdy work gloves can provide added protection when handling the drill and its accessories.

1. Proper Personal Protective Equipment

Ensuring that you have the right PPE for the job can make a world of difference in keeping you safe while operating a pneumatic hammer drill. Tianhe's commitment to safety extends beyond just manufacturing drilling equipment - they also guide you in choosing the right PPE for your specific drilling needs.

When it comes to choosing the right PPE for your specific drilling needs, Tianhe understands that one size does not fit all. That's why they offer personalized guidance on selecting the appropriate gear based on factors such as the type of material being drilled, the environment in which you'll be working, and any potential hazards present. This level of attention to detail ensures that you have the best possible protection while using their pneumatic hammer drill.

2. Ensuring a Secure Work Area

Before starting any drilling project with a pneumatic hammer drill, it's important to carefully inspect the work area for any potential hazards or obstacles. Clearing away debris, ensuring stable footing, and securing loose objects can help prevent accidents and maintain a safe environment for everyone involved in the project.

After ensuring the work area is free of hazards, it's essential to familiarize yourself with the pneumatic hammer drill and its safety features. Understanding how to properly operate the drill, including how to hold it securely and maintain control, is crucial for preventing accidents. Additionally, wearing appropriate personal protective equipment such as goggles, gloves, and ear protection can help minimize the risk of injury while using the drill.

3. Safely Operating the Pneumatic Hammer Drill

Proper operation of a pneumatic hammer drill is essential for both safety and efficiency. Always follow manufacturer guidelines for starting, stopping, and controlling the speed of the drill to avoid accidents or damage to the equipment. Tianhe's expertise in geotechnical drilling ensures that their pneumatic hammer drills are designed with user safety in mind.

Remember that prioritizing safety not only protects you but also contributes to successful project outcomes and long-term satisfaction with your pneumatic hammer drill investment.

Techniques for Effective Drilling

When using a pneumatic hammer drill, it's crucial to maintain the proper drilling speed and pressure for optimal results. Adjust the speed based on the hardness of the material you're drilling into - slower speeds for harder materials and faster speeds for softer ones. Additionally, always apply steady, even pressure to avoid damaging the drill or the surface you're working on.

1. Proper Drilling Speed and Pressure

To ensure efficient drilling with a pneumatic hammer drill, it's important to adjust the speed and pressure according to the type of material being drilled. For harder materials such as concrete or rock, use a slower speed and apply firm pressure to penetrate effectively without causing unnecessary strain on the drill. Conversely, when drilling into softer materials like wood or plastic, increase the speed and use lighter pressure to prevent over-penetration.

When drilling into any material, it's important to maintain control and accuracy to achieve the desired results. This can be achieved by holding the drill steady and applying consistent pressure to ensure a clean and precise hole. Additionally, using a guide or template can help to keep the drill on track and prevent any unwanted deviation in the drilling direction.

2. Maintaining Control and Accuracy

Maintaining control and accuracy while using a pneumatic hammer drill is essential for achieving precise results. Hold the drill firmly with both hands to minimize vibrations and keep it steady during operation. Additionally, use a depth stop or mark your desired drilling depth with tape to ensure accuracy.

To deal with tough materials when using a pneumatic hammer drill, it's important to use the right drill bit for the job. For harder materials such as concrete or masonry, use a carbide-tipped drill bit to ensure efficient drilling without excessive wear and tear on the equipment. Additionally, applying steady pressure and allowing the drill to work at its own pace can help prevent overheating and premature wear of the drill bit.

3. Tips for Dealing with Tough Materials

When faced with tough materials like concrete or rock, consider using Tianhe's DTH (Down-the-Hole) rock drill bits for superior performance. These specialized bits are designed to withstand high-impact conditions and deliver exceptional drilling efficiency in challenging environments. With their advanced design and durable construction, Tianhe's DTH rock drill bits are an indispensable tool for any pneumatic hammer drill user tackling demanding projects.

Troubleshooting and Maintenance

When using a pneumatic hammer drill, it's essential to be aware of common issues that may arise and how to solve them. One frequent problem is the drill bit getting stuck in the material being drilled. To resolve this, carefully reverse the drill to dislodge the bit, then continue drilling. Another issue is the drill not delivering enough power, which could be due to a worn-out piston or cylinder. In this case, it's best to have a professional inspect and repair the drill.

Common Issues and Solutions

Proper maintenance of your pneumatic hammer drill is crucial for its longevity and efficient performance. Regular cleaning of the tool, especially after drilling through tough materials like rock, helps prevent debris buildup that can affect its operation. Additionally, lubricating moving parts such as the piston and chuck ensures smooth functionality and reduces wear and tear on components.

Regular Cleaning and Lubrication

To extend the lifespan of your pneumatic hammer drill, it's important to follow manufacturer recommendations for maintenance intervals and procedures. This includes routine inspection of critical parts like seals, O-rings, and hoses for signs of wear or damage. Keeping these components in good condition not only prolongs the life of your drill but also ensures safe operation during drilling projects.

Extending the Lifespan of Your Pneumatic Hammer Drill

Proper maintenance is essential in ensuring the longevity of your pneumatic hammer drill. Regular cleaning and lubrication will help prevent wear and tear on the moving parts, keeping them running smoothly for years to come. Additionally, storing your drill in a dry and secure location when not in use will help protect it from damage and corrosion. By taking these simple steps, you can maximize the lifespan of your pneumatic hammer drill and get the most out of your investment. Remember, a well-maintained tool is a reliable tool!

Mastering the Art of Pneumatic Hammer Drill Operation

Now that you have a thorough understanding of pneumatic hammer drills and the importance of using them safely, you can confidently master the art of operating this powerful tool. By following the proper techniques and safety precautions, you can ensure efficient and effective drilling in every project.

Ensuring Safety and Efficiency in Every Project

With the right knowledge and equipment, such as Tianhe's DTH drill bit, you can guarantee safety and efficiency in all your drilling projects. By prioritizing safety measures and selecting high-quality tools, you can achieve optimal results while minimizing risks and downtime.

The Benefits of Using Tianhe's DTH Drill Bit

Tianhe's DTH drill bit offers exceptional quality and durability, making it an essential component for pneumatic hammer drills. With its superior performance in rock drilling applications, this drill bit ensures precision and effectiveness, ultimately enhancing the overall success of your projects.

Tianhe's DTH drill bit is designed to withstand the toughest drilling conditions, ensuring that it can handle any project with ease. Its exceptional quality and durability make it a reliable choice for professionals who require precision and effectiveness in their rock drilling applications. By choosing Tianhe's DTH drill bit, you can be confident that you are using a tool that will enhance the overall success of your projects, delivering impressive results time and time again.