Introduction

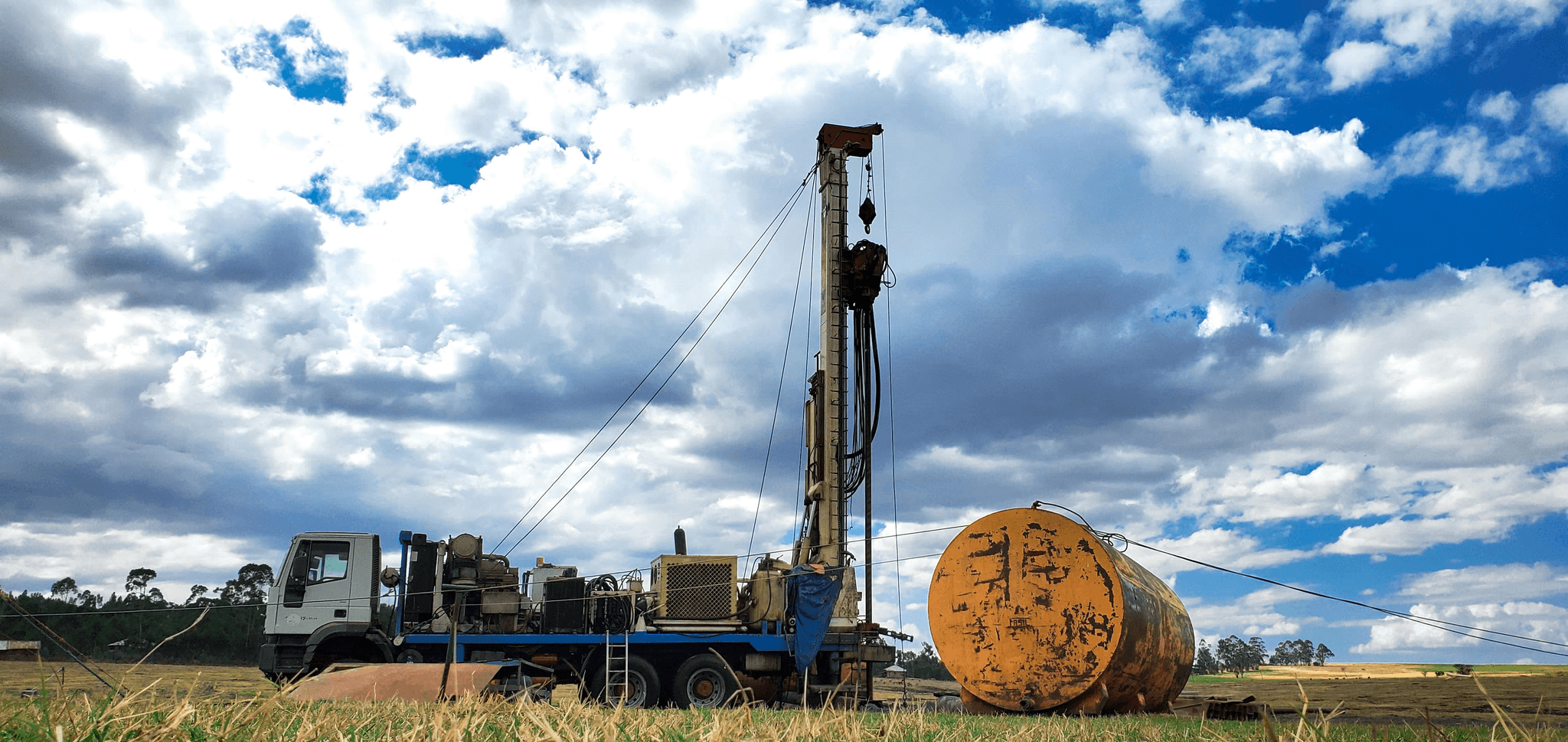

When it comes to the best truck-mounted water well drilling rig, understanding the composition and configuration selection is crucial. The drill rig equipment plays a pivotal role in the success of any drilling project, making it essential to explore these aspects in detail.

Understanding the Best Truck-Mounted Water Well Drilling Rig

Selecting the right composition and configuration of a truck-mounted water well drilling rig is vital for optimal performance and efficiency. It involves considering factors such as the type of terrain, depth of drilling, and specific project requirements.

Exploring Composition and Configuration Selection

The composition and configuration selection of a truck-mounted water well drilling rig involves choosing the right components and layout to ensure smooth operation and maximum output. This includes selecting the appropriate drill rig equipment that suits the geological conditions and project scope.

Importance of Drill Rig Equipment

Drill rig equipment forms the backbone of any drilling operation, impacting productivity, safety, and overall project success. Understanding its importance is key to making informed decisions when selecting a truck-mounted water well drilling rig.

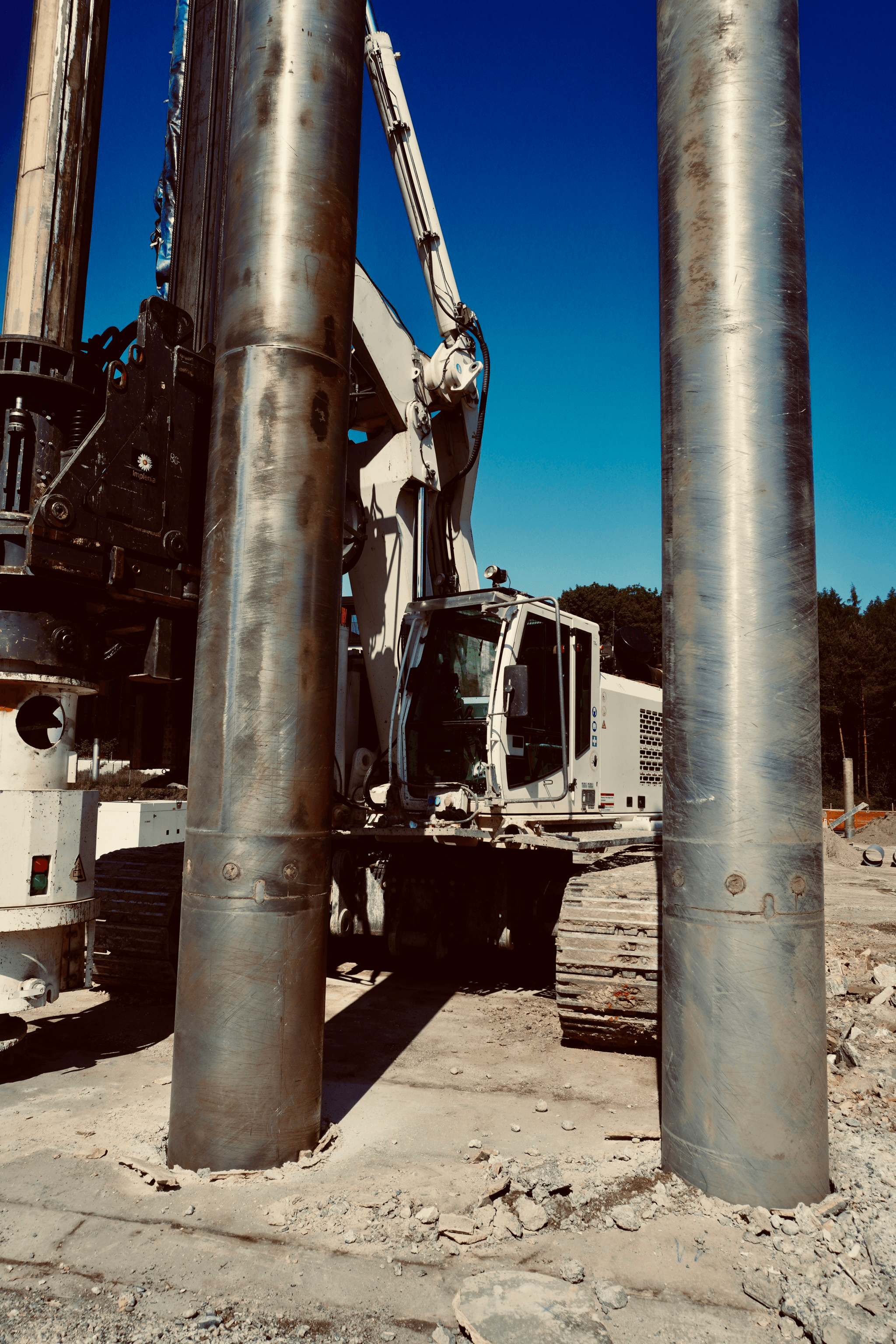

What is a Top Hammer Drill Rig?

Advantages and Applications

The top hammer drill rig offers several advantages, including high drilling speed, precision, and efficiency in various geological conditions. It is commonly used in construction, mining, and quarrying operations due to its ability to handle hard rock formations and deliver consistent results.

Core Components and Functionality

The core components of a top hammer drill rig include the hammer, drill bit, rotation unit, feed system, and control panel. The hammer strikes the drill bit to penetrate the rock while the rotation unit ensures continuous drilling. The feed system controls the downward pressure on the drill bit for optimal performance.

Comparison with Other Drilling Rigs

In comparison to other drilling rigs such as rotary and DTH (Down-The-Hole) rigs, the top hammer drill rig excels in its ability to provide accurate hole straightness and depth control. It also offers faster penetration rates and lower fuel consumption, making it a popular choice for various drilling applications.

What is Hammer Drilling?

How the Process Works

Hammer drilling involves using a top hammer drill rig to deliver rapid, short percussion blows to the drill bit, allowing it to penetrate hard rock formations efficiently. The rig's hydraulic system powers the hammer, which delivers high-impact energy to the drill bit, breaking up rock and creating boreholes for water well drilling or mining operations.

Suitable Geographical and Geological Conditions

This method is ideal for areas with hard rock formations such as granite, basalt, and quartzite. It is commonly used in regions with challenging geological conditions where traditional drilling methods may struggle to achieve the desired depth or speed. Hammer drilling rigs are particularly effective in mountainous terrain and areas with limited access.

Advantages Over Traditional Drilling Methods

Compared to conventional rotary drilling techniques, hammer drilling offers faster penetration rates and increased efficiency in hard rock formations. This results in reduced operational costs and shorter project timelines, making it a preferred choice for water well drilling and mining operations in challenging geological conditions.

Is a Hammer Drill Good for Drilling?

When considering the use of a hammer drill for drilling, it's essential to take into account the different types of wells that may need to be drilled. Whether it's for water wells, geothermal wells, or mineral exploration, the suitability of a hammer drill rig can vary based on the specific requirements of each type.

Considerations for Different Well Types

Water well drilling may require a different approach compared to geothermal or mineral exploration drilling. The composition and configuration selection of the truck-mounted water well drilling rig will need to be tailored to meet the specific geological conditions and depth requirements of each type of well.

Efficiency and Productivity

The efficiency and productivity of a hammer drill rig are significant factors in determining its suitability for drilling purposes. The ability to penetrate hard rock formations quickly and effectively can greatly impact the overall success and timeliness of a drilling project.

Impact on Overall Project Costs

The choice between using a hammer drill rig or other types of drilling rigs can have financial implications for a project. While initial costs may vary, considering factors such as maintenance, fuel consumption, and operational efficiency is crucial in evaluating the overall cost-effectiveness of using a hammer drill for drilling.

Now that we've delved into whether a hammer drill is suitable for various types of wells and its impact on project costs, let's explore the specialized features and applications of mining drilling rigs in the next section.

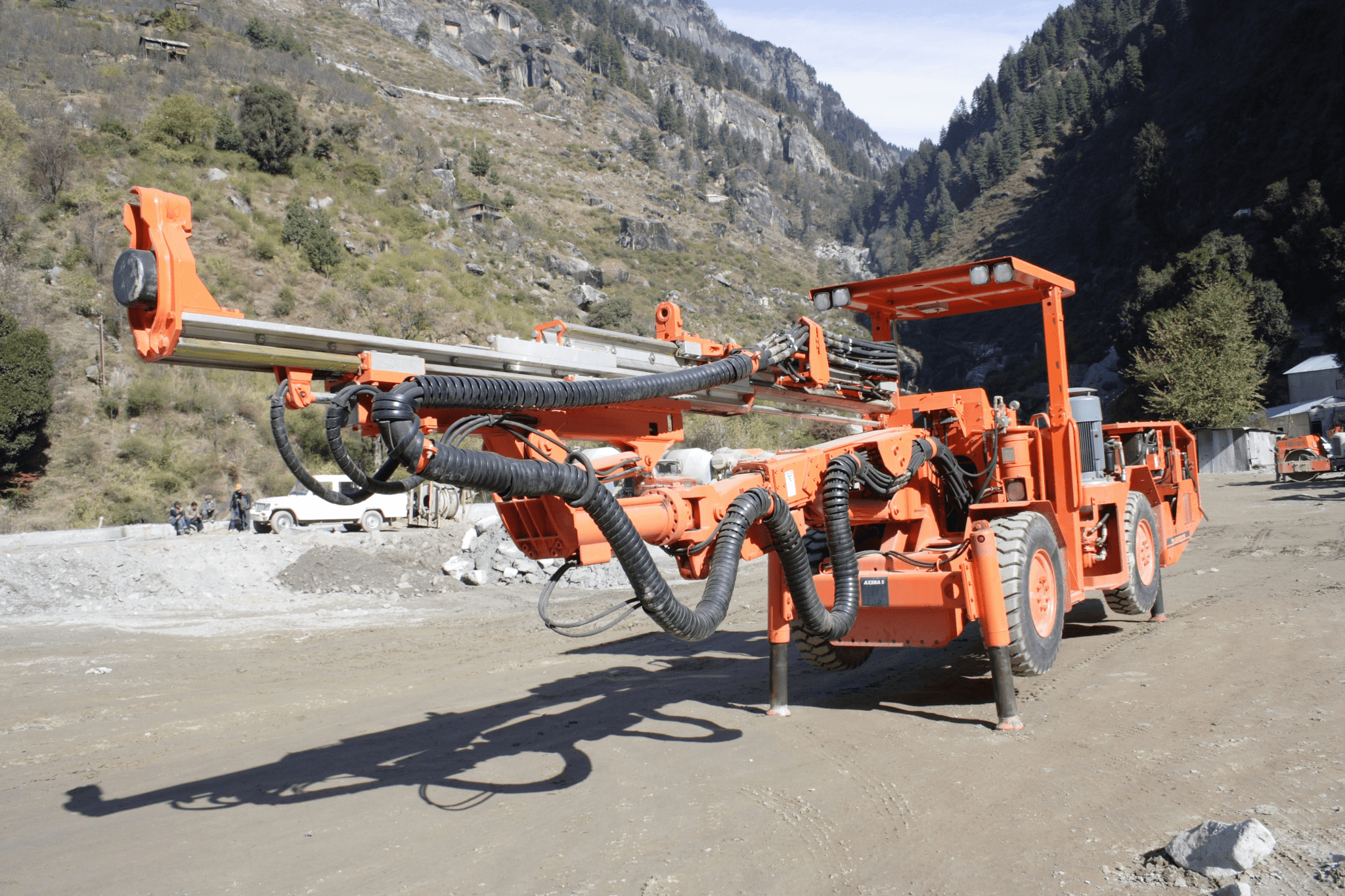

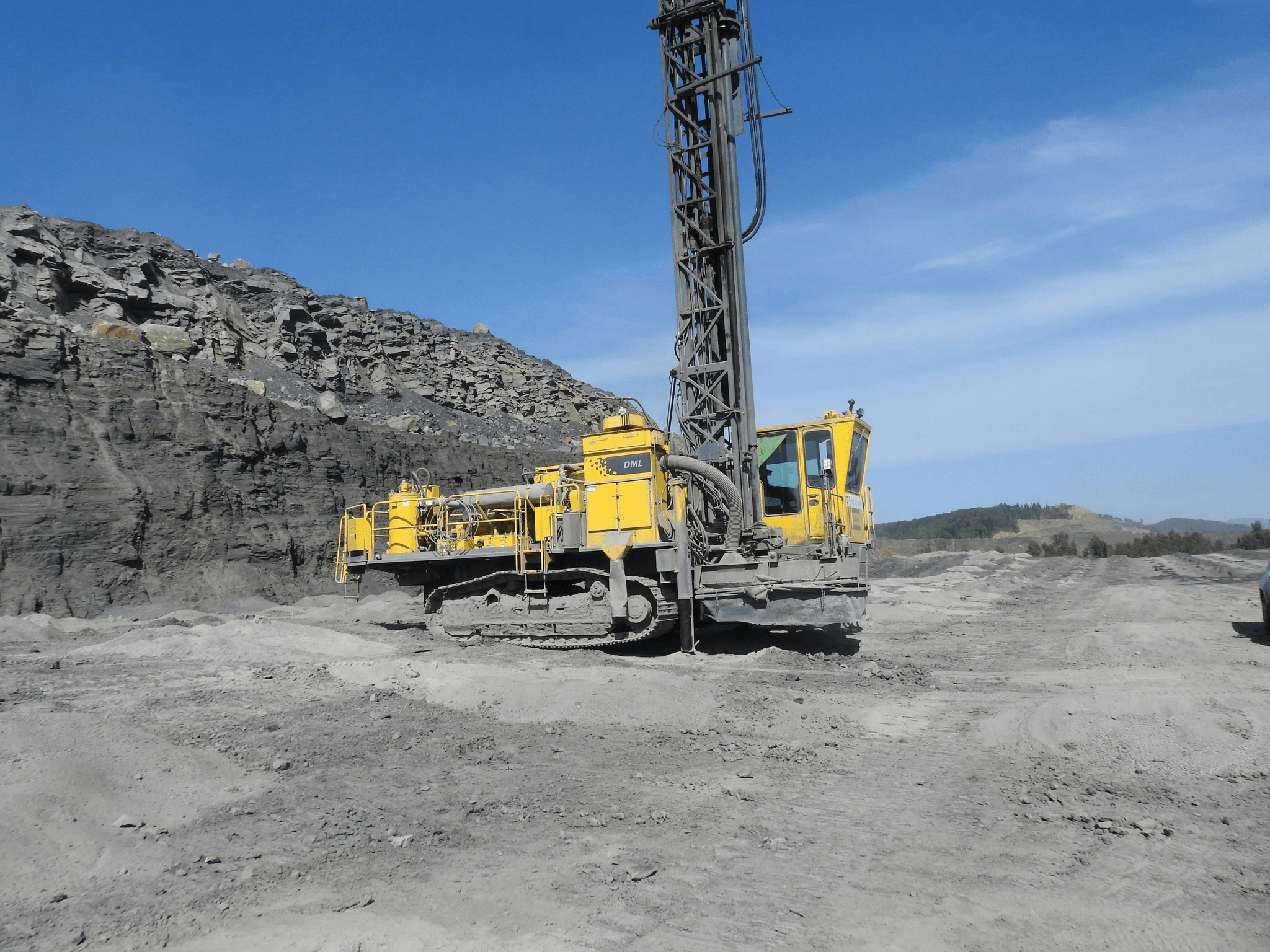

Mining Drilling Rig

Mining drilling rigs are equipped with specialized features designed to meet the unique demands of mining operations. These rigs are engineered to withstand the rigorous conditions of mining sites, offering enhanced durability and performance. From robust construction to advanced drilling capabilities, these rigs are tailored to maximize efficiency and productivity in mining applications.

Specialized Features for Mining Operations

Mining drilling rigs are equipped with heavy-duty components and specialized tools to handle the challenges of mining environments. These rigs often feature reinforced structures, powerful engines, and high-capacity hoisting systems to support the extraction of minerals from deep underground. Additionally, they may include advanced safety features such as emergency shut-off systems and protective barriers to ensure a secure working environment for operators.

Compatibility with Various Geological Conditions

Mining drilling rigs are designed to accommodate a wide range of geological conditions commonly encountered in mining operations. Whether it's hard rock formations or softer sedimentary layers, these rigs are engineered with versatile drilling capabilities that enable them to adapt to different types of strata. This flexibility allows mining companies to effectively explore and extract resources from diverse geological formations.

Enhanced Safety and Performance Standards

Safety is paramount in mining operations, and mining drilling rigs adhere to stringent safety standards to protect workers and equipment. These rigs are equipped with advanced monitoring systems, ergonomic controls, and safety interlocks to minimize the risk of accidents during drilling activities. Moreover, they undergo rigorous testing and certification processes to ensure compliance with industry regulations for safe and reliable performance.

In addition to safety features, mining drilling rigs are engineered for optimal performance in challenging environments. They are designed with high-powered engines, durable components, and advanced technology to ensure efficient and reliable drilling operations. These rigs are also equipped with environmental control systems to minimize emissions and reduce the impact on surrounding ecosystems, aligning with industry standards for sustainable mining practices.

System Introduction for TEAMWHOLE

Manufacturing Quality and Reliability

When it comes to the composition and configuration selection of a truck-mounted water well drilling rig, TEAMWHOLE stands out for its exceptional manufacturing quality and reliability. With a focus on precision engineering and durable materials, their drill rigs are built to withstand the toughest drilling conditions, ensuring long-lasting performance and minimal downtime.

With a commitment to innovation, TEAMWHOLE continually seeks to improve their truck-mounted water well drilling rigs by integrating advanced technologies and design features. By staying ahead of industry trends and customer needs, they are able to offer cutting-edge solutions that enhance efficiency and productivity in water well drilling and mining operations. This dedication to continuous improvement sets TEAMWHOLE apart as a leader in manufacturing quality and reliability.

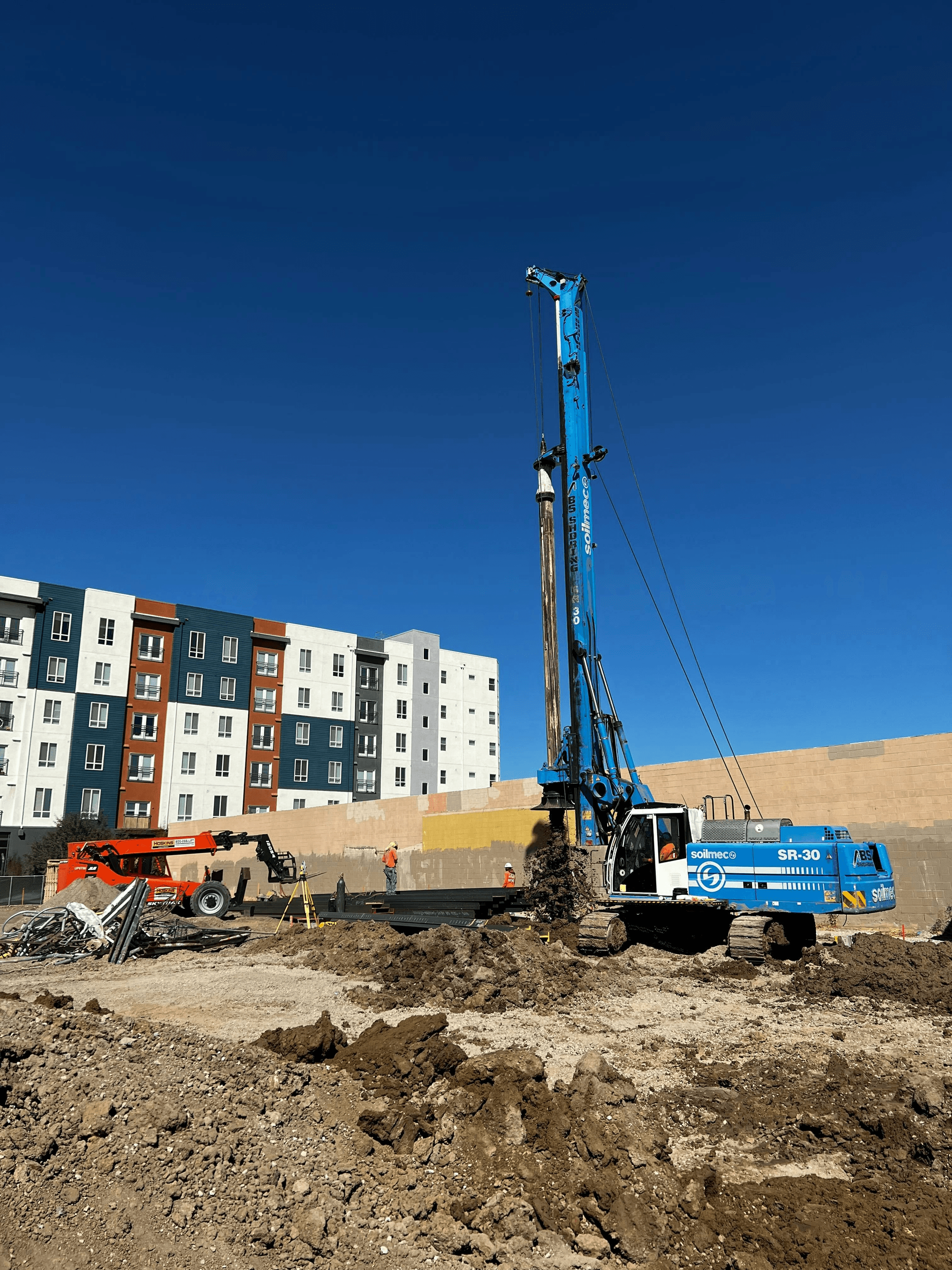

Application in Water Well Drilling and Mining

TEAMWHOLE's top hammer drill rig is designed for versatility, making it suitable for both water well drilling and mining operations. Its core components and functionality allow for efficient and precise drilling in various geological conditions, providing reliable results in different applications.

In addition to its versatility, TEAMWHOLE's top hammer drill rig offers significant advantages over competing brands in the water well drilling and mining industries. With its advanced technology and innovative design, this drill rig delivers superior performance, increased productivity, and reduced downtime. This means that operators can complete more drilling projects in less time, ultimately saving on costs and increasing overall efficiency. Furthermore, the rig's durability and reliability ensure that it can withstand the demanding conditions of both water well drilling and mining operations, making it a valuable asset for any project.

Advantages Over Competing Brands

One of the key advantages of TEAMWHOLE's drill rigs is their superior performance compared to competing brands. With advanced technology and innovative design features, these rigs offer increased productivity, reduced maintenance costs, and enhanced safety standards, making them the preferred choice for demanding drilling projects.

Conclusion

When selecting the right truck-mounted water well drilling rig, it's crucial to consider various factors such as geographical conditions, project requirements, and equipment compatibility. Understanding the composition and configuration selection of drill rigs is essential for optimal performance and efficiency. Making informed decisions about the drill rig equipment can significantly impact the success of water well drilling and mining operations.

Selecting the Right Truck-Mounted Water Well Drilling Rig

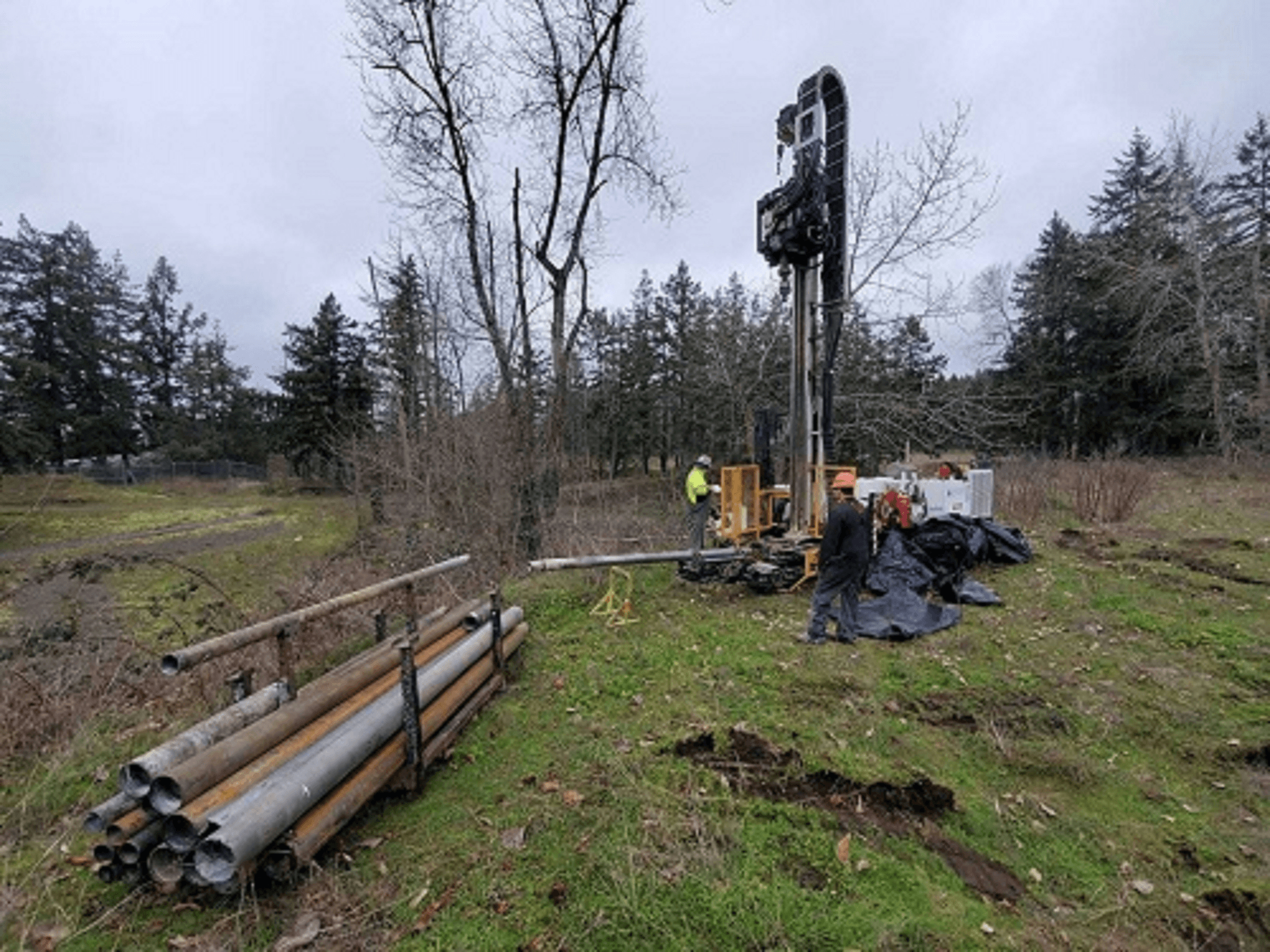

Choosing the most suitable truck-mounted water well drilling rig involves evaluating the specific needs of the project, including depth requirements, geological conditions, and available resources. It's essential to select a rig that offers versatility, durability, and efficient performance to ensure successful drilling operations in diverse environments.

After evaluating the specific needs of the project, it's important to consider the power and drilling capacity of the rig. A powerful rig with high drilling capacity will be able to handle more challenging geological conditions and reach greater depths. Additionally, it's crucial to assess the mobility and accessibility of the rig, especially if the project requires drilling in remote or difficult-to-reach locations. Choosing a truck-mounted water well drilling rig that can easily navigate through rugged terrain will ensure that drilling operations can be conducted efficiently and effectively.

Factors to Consider for Optimal Performance

Factors such as engine power, hydraulic system capacity, and drilling depth capabilities play a crucial role in determining the optimal performance of a truck-mounted water well drilling rig. Additionally, considering the mobility, stability, and ease of operation of the rig is vital for achieving efficient and productive results in various drilling applications.

Furthermore, the durability and reliability of the rig's components, such as the drill pipe, drilling bits, and mud pump, are essential factors to consider for optimal performance. Choosing high-quality materials and well-maintained equipment can minimize downtime and increase the overall efficiency of the drilling operations. Additionally, the ability to adapt to different geological conditions and varying terrains is crucial for ensuring consistent and successful well drilling outcomes.

Making Informed Composition and Configuration Decisions

Understanding the composition and configuration of a drill rig is not just about selecting the right equipment; it's also about ensuring that everything works together seamlessly. Compatibility between drill rods, hammers, and bits is crucial for achieving optimal drilling performance. By carefully evaluating these components and their suitability for different geological formations, project managers can avoid costly mistakes and delays.

Now that you have gained valuable insights into top hammer drill rigs, hammer drilling processes, mining drill rigs, and more – you are equipped with essential knowledge to make informed decisions when selecting a truck-mounted water well drilling rig for your next project!