Introduction

The choice of drill attachments is crucial to efficient and effective drilling. Whether you're working with a power drill or an impact driver, having the right drill bits can make all the difference in achieving precision and maximizing impact. In this guide, we'll explore the options available, including button bit, DTH hammer, and DTH drill bit, to help you decide on your drilling needs.

Understanding the Importance of DTH Drill Attachments

Drill attachments are like a toolbox full of superpowers for your drill. They transform your trusty drill from a simple hole maker into a versatile tool that tackles various tasks. By understanding the different attachments available, you'll be equipped to select the perfect partner for any drilling project.

- Precision Punches: Button bits, with their compact design, create small, clean holes ideal for intricate rotary drilling tasks.

- Tough Rock Tamers: DTH hammers are the titans of the attachment world. They easily conquer challenging rock formations, making them perfect for large-scale projects.

- Speed and Straightness: DTH drill bits are the ultimate combo of efficiency and accuracy. They deliver impressive penetration rates while ensuring straighter holes, a valuable asset for many drilling applications.

Understanding these unique functionalities empowers you to choose the right attachment and confidently conquer any drilling challenge. So, next time you reach for your drill, remember the power of attachments and unlock a world of drilling possibilities!

Exploring the Options: Button Bit, DTH Hammer, and DTH Drill Bit

Choosing the right drill attachment can significantly impact the efficiency and success of your drilling project. Here's a breakdown of three popular options:

- Button Bit: Renowned for its precision and drilling efficiency, the button bit features tungsten carbide inserts that excel in hard rock formations.

- DTH Hammer: Prioritizing power and impact, the DTH hammer delivers strong blows that are ideal for breaking through tough materials.

- DTH Drill Bit: Designed for durability and deep penetration, the DTH drill bit is built to withstand demanding drilling projects in various conditions.

Understanding the strengths of each attachment can help you make an informed decision. The button bit reigns supreme when dealing with rocky terrain that demands precision drilling. On the other hand, projects requiring maximum impact and power might be better suited for the DTH hammer. Finally, the DTH drill bit is a reliable choice for long-lasting drilling performance across diverse conditions.

Factors to Consider When Choosing the Best DTH Drill Attachments

Selecting the best Down-The-Hole (DTH) drill attachments requires careful consideration of various factors. Here's a breakdown of key aspects to evaluate before making your choice:

- Compatibility: Ensure the attachments seamlessly integrate with your existing drilling equipment. Opt for versatile options that work with various drilling rigs and machinery. This avoids needing separate attachments for different setups, saving you time and money. Consider ease of installation and removal for efficient project transitions.

- Performance: Evaluate the attachment's drilling efficiency in your target material. Research factors like penetration rates, footage drilled per bit life, and overall drilling speed. Choose attachments optimized for the specific material you'll work with, maximizing productivity and minimizing drilling time.

- Durability: DTH drilling can be demanding. Select attachments built with high-quality, wear-resistant materials to withstand tough conditions. Consider the manufacturer's reputation and warranty offerings. Durable attachments minimize downtime due to repairs or replacements, leading to long-term cost savings.

- Cost-Effectiveness: While upfront cost is important, consider the total cost of ownership. Factor in the attachment's lifespan, maintenance needs, and potential repair costs. Attachments with a lower initial price might not be cost-effective if they require frequent replacements or extensive maintenance.

- Customer Reviews: Read reviews from other users to gain valuable insights into the attachment's real-world performance, durability, and ease of use. Customer experiences can highlight potential strengths or weaknesses you might miss through technical specifications alone.

By carefully considering these factors, you'll be well-equipped to choose the optimal DTH drill attachments for your specific needs, ensuring efficient, cost-effective, and successful drilling projects.

Types of DTH Drill Attachments

1. Button Bit: Achieving Precision and Efficiency

When it comes to precision drilling, button bits are the go-to choice for achieving accurate and efficient results. These drill attachments are designed with strategically placed buttons that enable smooth and precise penetration into various rock formations. With their advanced design and cutting-edge technology, button bits offer exceptional durability and performance, making them essential for any drilling operation.

2. DTH Hammer: Maximizing Impact and Power

The DTH hammer is a powerhouse for maximizing impact and power during drilling operations. This drill attachment delivers high-energy blows to the drill bit, enabling rapid and efficient penetration into hard rock formations. With its robust construction and superior impact force, the DTH hammer is designed to tackle even the toughest drilling challenges with ease, making it an indispensable tool for achieving optimal results in demanding drilling projects.

3. DTH Drill Bit: Enhancing Penetration and Durability

When it comes to enhancing penetration and durability, the DTH drill bit stands out as a top performer in the world of drill attachments. Engineered with precision-engineered cutting structures and high-quality materials, this drill bit is built to withstand extreme drilling conditions while delivering exceptional performance. Its ability to enhance penetration rates while maintaining long-lasting durability makes the DTH drill bit valuable for maximizing productivity in any drilling operation.

Furthermore, the DTH drill bit's innovative design allows for efficient energy transfer, resulting in faster drilling speeds and reduced equipment wear. This means less downtime for maintenance and repairs, ultimately saving drilling operations time and money. Additionally, its advanced engineering ensures consistent performance across various rock formations, making it a versatile and reliable tool for any drilling project.

Compatibility with Different Drilling Setups

When identifying the right attachments for various drilling equipment, it's crucial to consider the specific needs of your drilling projects. Whether working with a power drill, hammer drill, or impact driver, choosing the appropriate drill bits and attachments can make all the difference in achieving optimal results. By understanding the compatibility of different drill attachments with various drilling setups, you can ensure seamless integration and enhance overall efficiency.

Identifying the Right Attachments for Various Drilling Equipment

Selecting the right drill attachments for different drilling equipment involves assessing factors such as size, power output, and intended application. For instance, when using a power drill for precision work, a button bit may be the ideal choice due to its ability to achieve accuracy and efficiency. On the other hand, a DTH hammer might be more suitable for heavy-duty applications that require maximum impact and power. By understanding the unique capabilities of each attachment in relation to your specific drilling equipment, you can make informed decisions that lead to optimal performance.

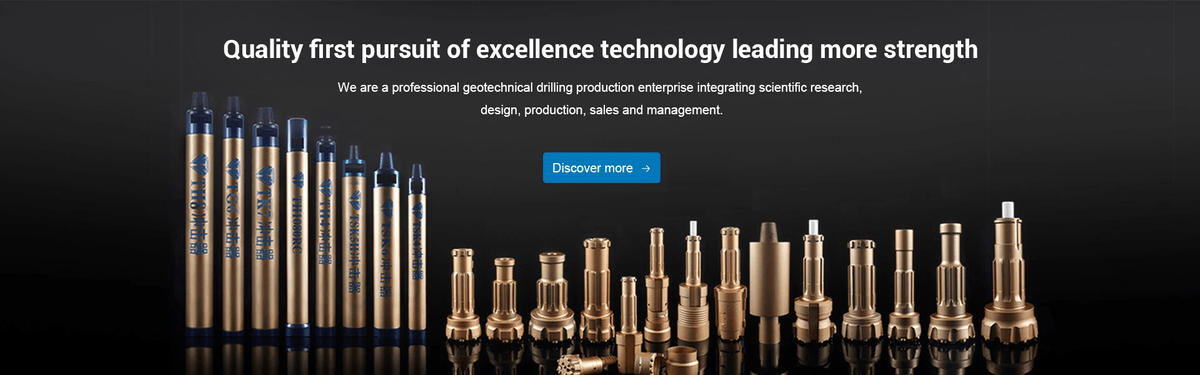

Ensuring Seamless Integration with Tianhe Drilling Machinery

Compatibility is key to ensuring seamless integration with Tianhe drilling machinery. Tianhe offers a wide range of high-quality DTH drill attachments designed to work seamlessly with its state-of-the-art drilling equipment. By choosing compatible attachments from Tianhe's product line, you can maximize the performance and longevity of your drilling setup while benefiting from enhanced efficiency and reliability. With a focus on precision engineering and advanced technology, Tianhe's drill attachments are engineered to deliver exceptional results across diverse drilling setups.

In addition to being compatible with Tianhe drilling machinery, the high-quality DTH drill attachments undergo rigorous performance and durability evaluations. This ensures that they can withstand the demands of various drilling conditions and deliver consistent results over time. With a focus on longevity and reliability, Tianhe's attachments are built to endure heavy usage and harsh environments, making them a cost-effective choice for any drilling operation.

Performance and Durability Evaluation

Assessing the Reliability and Longevity of Drill Attachments

When evaluating the reliability and longevity of drill attachments, factors such as wear resistance, corrosion protection, and overall build quality must be considered. Drill bits' ability to maintain sharpness and integrity over time directly impacts their performance and durability in various drilling conditions. By conducting thorough testing and analysis, we can ensure that our drill attachments are built to withstand the demands of heavy-duty drilling operations.

Understanding the Impact of Material and Design on Performance

The material composition and design of drill attachments play a significant role in determining their overall performance. High-quality steel alloys, advanced carbide inserts, and innovative bit designs can greatly enhance drilling efficiency, penetration rates, and productivity. Understanding how different materials and designs interact with various rock formations is essential for optimizing performance and achieving reliable results in challenging drilling environments.

The choice of material and design in drill attachments also impacts their durability and longevity. High-quality steel alloys and advanced carbide inserts can resist wear and tear, resulting in longer tool life and reduced maintenance costs. Additionally, innovative bit designs can minimize vibration and heat generation, reducing stress on the equipment and prolonging its operational lifespan.

Cost-Effectiveness and ROI

When it comes to drill attachments, the investment value of different options is a crucial factor to consider. By analyzing the long-term performance, durability, and efficiency of drill bits and hammers, you can make an informed decision that maximizes your return on investment.

Analyzing the Investment Value of Different Drill Attachments

Choosing the right drill attachments can significantly impact your drilling operations' overall cost-effectiveness and return on investment. By carefully evaluating factors such as durability, precision, and compatibility with your drilling equipment, you can invest wisely in tools that will deliver long-term value.

Maximizing Efficiency and Minimizing Operational Costs with the Right Choice

Selecting the most suitable drill attachments for your specific drilling needs is essential for maximizing efficiency while minimizing operational costs. Whether you're looking for powerful hammer drills or precision-oriented button bits, making the right choice can significantly save time, labor, and maintenance expenses.

Remember that choosing high-quality drill attachments is an investment in your drilling operations' success. By carefully considering their value and impact on efficiency and costs, you can make a decision that ensures optimal performance while delivering a strong return on investment.

Customer Reviews and Recommendations

Learning from Real-World Experiences and Insights

Customer reviews are a goldmine of information about drill attachments. From construction professionals to DIY enthusiasts, real-world experiences provide valuable insights into the performance and durability of different drill bits and attachments. By learning from their experiences, you can make informed decisions and avoid costly mistakes when choosing the equipment for your drilling needs.

Leveraging Tianhe's Expertise and Industry Reputation

Tianhe has built a solid reputation in the industry for providing top-quality drill attachments that deliver exceptional performance. With years of expertise in manufacturing drill bits, hammers, and other attachments, they have earned customers' trust worldwide. By leveraging Tianhe's expertise and industry reputation, you can be confident that you are investing in reliable, durable, and high-performing drill attachments that will meet your drilling requirements.

By choosing Tianhe's drill attachments, you are investing in high-quality products and benefiting from their extensive knowledge and experience in the industry. Their commitment to innovation and continuous improvement ensures that you will always have access to the latest technology and advancements in drilling equipment. With Tianhe as your partner, you can be confident that your drilling operations will be efficient, productive, and cost-effective.

Ensure Optimal Performance and Longevity with the Right Attachments

When making an informed decision about your DTH drilling needs, it's crucial to prioritize the quality and reliability of your drill attachments. You can maximize efficiency and minimize operational costs in the long run by ensuring optimal performance and longevity with the right attachments. Partnering with Tianhe for quality DTH drill attachments is a smart investment that guarantees superior results for your drilling projects.

Making an Informed Decision for Your DTH Drilling Needs

Choosing the right drill attachments is essential for achieving successful drilling operations. Whether you need drill bits, hammers, or impact drivers, understanding your project's specific requirements will help you make an informed decision. With a wide range of options available, it's important to consider factors such as precision, power, and durability to ensure that your chosen attachments can meet the demands of your drilling tasks.

To achieve optimal performance and longevity in your drilling operations, selecting high-quality attachments is key. Investing in durable materials and innovative designs will enhance the efficiency and effectiveness of your equipment. By prioritizing reliability and durability, you can ensure that your drill attachments deliver consistent results while minimizing downtime due to maintenance or replacement needs.

Partnering with Tianhe for Quality DTH Drill Attachments

Tianhe stands out as a trusted provider of top-notch DTH drill attachments designed to meet the highest industry standards. Committed to delivering exceptional quality and performance, Tianhe offers a comprehensive range of drill bits, hammers, and other attachments engineered for maximum efficiency and durability. By partnering with Tianhe, you can access reliable solutions that cater to all your DTH drilling requirements.