Introduction

When it comes to power tools, the drill head is a crucial component that can make or break your drilling experience. Whether you're a professional in the construction industry or a DIY enthusiast, knowing what to look for in drill heads is essential for achieving efficient and effective drilling results. Understanding the importance of quality drill bits goes hand in hand with this, as they are the key to ensuring precision and durability in your drilling projects. The role of drill heads in efficient drilling cannot be overstated, as they directly impact the performance and longevity of your power tools.

What to Look for in Drill Heads

Selecting the appropriate drill bit is crucial for a successful drilling project. Here are key factors to consider:

1. Material Composition: Different materials require specific drill bit types.

- High-Speed Steel (HSS) bits are suitable for wood, plastic, and soft metals.

- Titanium-coated HSS bits offer increased durability for these materials.

- Tungsten Carbide-tipped bits excel in hard materials like masonry, concrete, and tile.

2. Shank Compatibility: Ensure the drill bit's shank (the end inserted into the drill) matches your power tool's chuck type. Common shank designs include round, hex, and SDS.

3. Drill Bit Type: Beyond standard twist drill bits, various specialty bits exist for specific tasks:

- Hole saws for creating large-diameter holes.

- Forstner bits for clean, flat-bottomed holes in wood.

- Masonry bits for drilling through hard and brittle materials.

4. Durability: Consider the workload and desired lifespan.

- Basic HSS bits are affordable but wear down quicker.

- Titanium-coated and Carbide-tipped bits provide extended life for frequent use.

By carefully considering these factors, you'll choose the drill bit best suited for your project, ensuring clean, efficient drilling and successful completion of your task.

Understanding the Importance of Quality Drill Bits

Quality drill bits are essential for achieving precise and clean cuts during drilling operations. Investing in high-quality drill bits will enhance your power tools' performance and ensure safety and efficiency in various drilling applications. When you use low-quality drill bits, you risk breaking or becoming dull quickly, leading to an inefficient and potentially dangerous drilling process. You can avoid these issues by choosing quality drill bits and enjoy smooth, accurate drilling with minimal effort.

The Role of Drill Heads in Efficient Drilling

Drill heads play a critical role in ensuring efficient drilling operations by providing stability, precision, and durability to power tools. Choosing the right drill bits for specific applications can maximize productivity and minimize downtime associated with tool maintenance or replacement.

Drill heads with hard rock drill bits are designed to withstand tough drilling conditions through solid rock formations. These specialized drill heads feature tungsten carbide or diamond inserts that provide exceptional hardness and resistance to wear, ensuring longevity and consistent performance in challenging environments. With the ability to maintain sharpness and stability during prolonged use, hard rock drill heads contribute to efficient drilling operations by reducing the frequency of bit changes and optimizing overall productivity.

Key Features of Hard Rock Drill Heads

The material composition of drill heads is crucial when it comes to hard rock drilling. High-quality steel alloys are often used to ensure durability and strength, allowing the drill bits to withstand the tough demands of hard rock drilling. These materials also contribute to the longevity and performance of the drill heads, making them a reliable choice for challenging drilling conditions.

1. Material Composition of Drill Heads

The material composition of drill heads significantly affects their overall performance and durability. High-carbon steel, cobalt steel, and tungsten carbide are commonly used to manufacture hard rock drilling drill bits. These materials offer exceptional hardness and resistance to wear, ensuring that the drill bits remain sharp and effective even when subjected to intense drilling pressures.

In addition to the material composition, the design and shape of drill heads also play a crucial role in their performance. The geometry of the drill head affects the efficiency of the drilling process and the accuracy and precision of the hole being drilled. Manufacturers often invest in research and development to create innovative designs that optimize drilling performance and minimize wear on the drill bits.

2. Compatibility with Different Drilling Equipment

Another key feature of hard rock drill heads is their compatibility with various drilling equipment. Whether it's handheld power tools or heavy-duty industrial drills, the design and specifications of the drill bits ensure seamless integration with different types of equipment. This versatility allows for greater flexibility in choosing the right tools for specific drilling applications.

In addition to being compatible with various drilling equipment, hard rock drill heads are also designed for maximum durability. The materials and construction of the drill bits are engineered to withstand the rigors of heavy-duty drilling operations, ensuring that they can hold up under intense pressure and friction. This durability not only extends the lifespan of the drill heads but also reduces the need for frequent replacements, ultimately saving users time and money.

3. Durability of Drill Heads

Durability is a non-negotiable feature when it comes to hard rock drill heads. The ability to withstand abrasive surfaces, high-impact forces, and extreme temperatures is essential for prolonged use in challenging geological conditions. High-quality materials and precision engineering contribute to the durability of these drill heads, making them a valuable investment for any drilling operation.

Now that we've explored the key features of hard rock drill heads, let's examine the factors to consider when choosing these essential tools for geotechnical drilling operations.

Factors to Consider When Choosing Drill Heads

1. Size and Shape Variations of Drill Bits

When selecting drill heads, it's crucial to consider drill bits' size and shape variations. Different projects require different sizes and shapes to ensure precise drilling. The right combination of size and shape can make all the difference in achieving optimal results with power tools. The material being drilled into must be considered when choosing the appropriate drill bit. For example, drilling into metal requires a different type of bit than drilling into wood or plastic. Understanding these differences can help ensure successful drilling outcomes.

2. Performance in Hard Rock Drilling Conditions

The performance of drill bits in hard rock drilling conditions is a key factor to consider when choosing drill heads. High-quality, durable bits specifically designed for hard rock drilling will ensure efficient and effective results, minimizing downtime and maximizing productivity with the drill.

High-quality drill bits designed for hard rock drilling deliver efficient and effective results and offer cost-effectiveness and longevity. By investing in durable bits, companies can minimize downtime and reduce the frequency of bit replacements, ultimately saving money in the long run. Additionally, these high-quality drill bits are built to withstand the tough conditions of hard rock drilling, ensuring a longer lifespan and consistent performance.

3. Cost-Effectiveness and Longevity

Cost-effectiveness and longevity are essential factors when choosing drill heads for power tools. While upfront costs are important, it's equally crucial to consider the long-term value and durability of the drill bits. Investing in high-quality, long-lasting drill heads can ultimately save time and money in the long run.

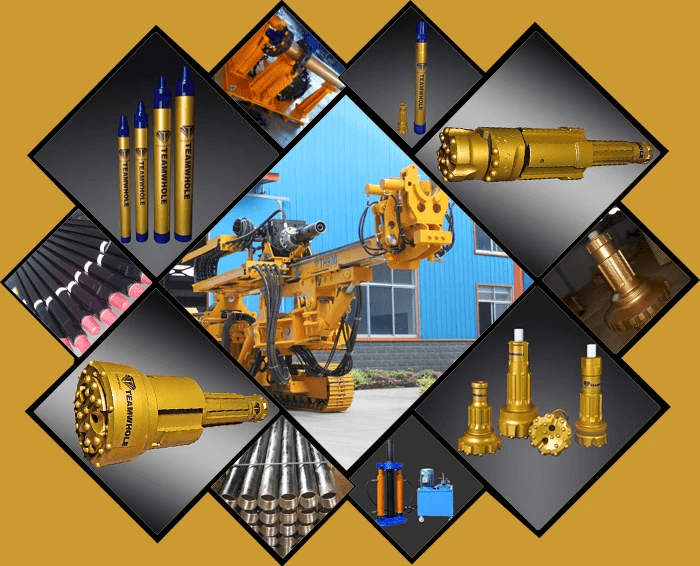

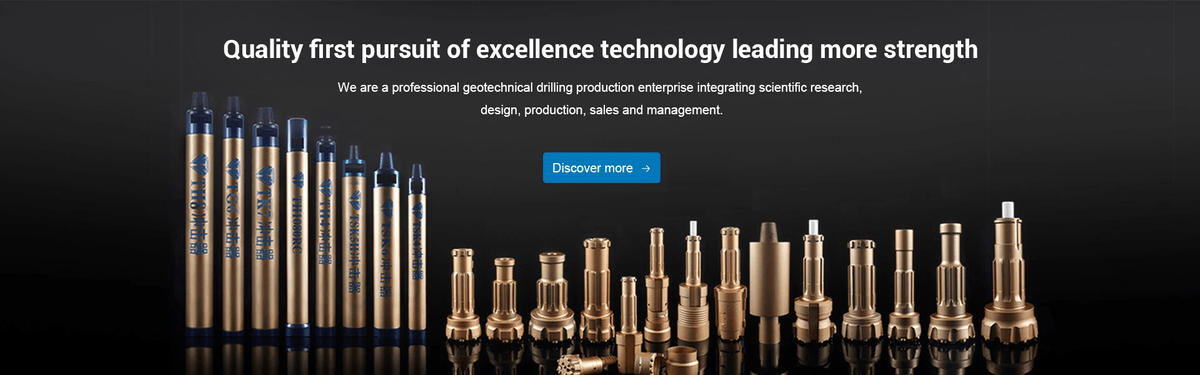

Tianhe's Expertise in Hard Rock Drill Heads

Tianhe has established itself as a leader in the industry thanks to its cutting-edge technologies that are revolutionizing the world of drill heads. With a focus on innovation, Tianhe is constantly pushing the boundaries to develop drill heads that deliver unmatched performance and durability.

Tianhe's Innovative Technologies

Tianhe's state-of-the-art manufacturing processes and advanced materials ensure that its drill heads can withstand the toughest drilling conditions. Its innovative designs and engineering expertise have also led to the development of drill bits that offer superior precision and efficiency, making it a top choice for geotechnical drilling professionals.

Tianhe's Range of Drill Head Options

Tianhe offers diverse drill head options to cater to different drilling requirements. From standard drill bits for general applications to specialized drill bits for hard rock drilling, Tianhe provides a comprehensive selection of power tools compatible with various drilling equipment, ensuring versatility and flexibility for different projects.

Tianhe's Commitment to Quality and Performance

Quality is at the core of everything Tianhe does, and its commitment to excellence is reflected in its range of high-performance drill heads. Each product undergoes rigorous testing and quality control measures to ensure reliability and longevity. This gives customers peace of mind, knowing they are investing in top-tier drill bits for their projects.

Best Practices for Maintaining Drill Heads

Drill heads are essential for any drilling operation, and proper maintenance is crucial to ensure their longevity and optimal performance. Proper cleaning and storage techniques play a significant role in preserving the integrity of drill heads. After each use, it's important to thoroughly clean the drill bits to remove any debris or residue that could affect their performance. Store them in a dry, cool place away from direct sunlight to prevent corrosion and damage.

1. Proper Cleaning and Storage Techniques

When cleaning drill heads, use a mild detergent or solvent to remove any built-up dirt or grime. Dry them completely before storing them to prevent rusting or corrosion. Additionally, consider using protective cases or organizers to keep drill bits organized and prevent them from getting damaged during storage. By following these simple cleaning and storage practices, you can extend the lifespan of your drill heads and ensure they remain in top condition for future use.

2. Regular Inspection and Maintenance Schedule

In addition to proper cleaning and storage, regular inspection and maintenance are essential for preserving the quality of drill heads. Implement a routine maintenance schedule that includes checking for signs of wear or damage, such as dull edges or cracks in the material. Replace any worn-out or damaged drill bits promptly to prevent compromising the efficiency of your drilling equipment.

3. Extending the Lifespan of Drill Heads

To extend the lifespan of your drill heads, consider investing in high-quality power tools that are compatible with various types of drill bits. Using the right equipment for specific drilling tasks can minimize wear and tear on your drill heads, ultimately extending their longevity. By following these best practices for maintaining drill heads, you can maximize their performance and get the most out of your investment.

Selecting the Right Drill Head for Specific Applications

When selecting the right drill head for specific applications, it's crucial to consider the unique needs of different projects. Whether it's a small-scale residential construction project or a large-scale commercial drilling operation, understanding the specific requirements of each project is essential in choosing the most suitable drill head.

1. Identifying the Needs of Different Projects

Before selecting a drill head, it's important to assess the scope and scale of the drilling project. Factors such as the rock formations' depth, diameter, and material composition will influence the type of drill head needed for optimal performance. You can ensure that the chosen drill head is perfectly suited by identifying these specific needs.

2. Matching Drill Head Features to Specific Geological Conditions

Different geological conditions require different features in a drill head. A drill head with strong tungsten carbide inserts may be necessary for hard rock drilling to withstand abrasive materials. A more aggressive cutting structure may be required for efficient penetration in softer formations. Matching these features to specific geological conditions ensures maximum productivity and effectiveness.

3. Maximizing Efficiency and Productivity with the Right Drill Heads

Ultimately, selecting the right drill head is all about maximizing efficiency and productivity on the job site. By carefully considering project needs and geological conditions, you can choose a drill head that meets and exceeds expectations in terms of performance and longevity.

Now that we've covered how to select the right drill head for specific applications, let's explore best practices for maintaining these essential power tools to extend their lifespan and ensure optimal performance over time.

Ensure Optimal Performance with Quality Drill Bits

When making informed decisions for drill head selection, it's crucial to consider the key features of hard rock drill heads and the factors that determine their performance in different drilling conditions. You can maximize efficiency and productivity with power tools by ensuring optimal performance with quality drill bits. Tianhe's expertise in geotechnical drilling gives them a professional edge, offering innovative technologies and a range of drill head options to meet your specific needs.

Making Informed Decisions for Drill Head Selection

Choosing the right drill head is essential for efficient drilling operations. Understanding the material composition, compatibility with different equipment, and durability of drill heads will help you make informed decisions when selecting the best option for your projects. Consider size and shape variations of drill bits to match specific geological conditions, ensuring cost-effectiveness and longevity in your operations.

Quality drill bits are essential for achieving optimal performance in drilling operations. Investing in high-quality bits will ensure precision and efficiency, whether using a handheld power tool or a larger industrial drill. By maintaining proper cleaning and storage techniques and implementing a regular inspection and maintenance schedule, you can extend the lifespan of your drill heads and maximize their performance.

The Professional Edge of Tianhe in Geotechnical Drilling

Tianhe stands out as a leader in geotechnical drilling, offering expertise in hard rock drill heads designed to meet various projects' demands. With a commitment to quality and performance, Tianhe provides innovative technologies and various options to cater to specific drilling needs. Their professional edge lies in their ability to match drill head features with specific geological conditions, ensuring maximum efficiency and productivity.