Introduction

Having the right tools is essential for tackling tough drilling tasks. Rotary hammer drill bits are specially designed with rotary hammers, providing the power and precision to bore through concrete, masonry, and other hard materials. Understanding the different types of drill bits for hammer drills and their unique features is crucial for achieving optimal drilling results.

Understanding Rotary Hammer Drill Bits

Rotary hammer drill bits are engineered to withstand the high-impact forces generated by rotary hammers, making them distinct from standard drill bits. They typically feature carbide tips or cutting edges that deliver exceptional durability and performance when used with a hammer drill. These specialized bits come in various designs to accommodate drilling applications and materials.

In addition to their durability and performance, the design of rotary hammer drill bits also plays a crucial role in their effectiveness. Some bits are designed with flutes or grooves to remove debris and reduce heat buildup during drilling, which helps prevent bit wear and prolongs the tool's lifespan. Other bits may feature a specially engineered head shape to optimize drilling speed and efficiency, making them ideal for specific applications such as concrete drilling or chiseling.

Importance of Quality Drill Bits

Investing in high-quality drill bits is crucial for any project requiring a rotary hammer. Here's how they benefit you:

- Enhanced Efficiency: Sharp, durable bits ensure clean cuts and faster drilling, saving you time and effort.

- Reduced Equipment Wear: Substandard bits can strain your drill, leading to premature wear and potential damage.

- Precise Drilling: Quality bits deliver clean, accurate holes, minimizing rework and ensuring project success.

- Improved Safety: Stronger bits are less prone to breakage, reducing the risk of accidents and injuries on the job site.

By prioritizing quality drill bits, you achieve efficient operations, protect your equipment, and promote a safer work environment.

Choosing the Right Rotary Hammer Drill Bit

Selecting the appropriate rotary drill bit for a specific drilling task involves considering factors such as material composition, bit size and length, and compatibility with hammer drills. The right choice of bit can significantly impact drilling speed, accuracy, and overall performance. Understanding these considerations is essential for maximizing the effectiveness of rotary hammer drill bits.

Regarding material composition, it's important to choose a rotary hammer drill bit specifically designed for the type of material you will be drilling into. For example, masonry bits are ideal for drilling into concrete, brick, and stone, while carbide-tipped bits are better suited for drilling into metal and wood. By selecting the right bit for the job, you can ensure that your drilling task is completed efficiently and precisely.

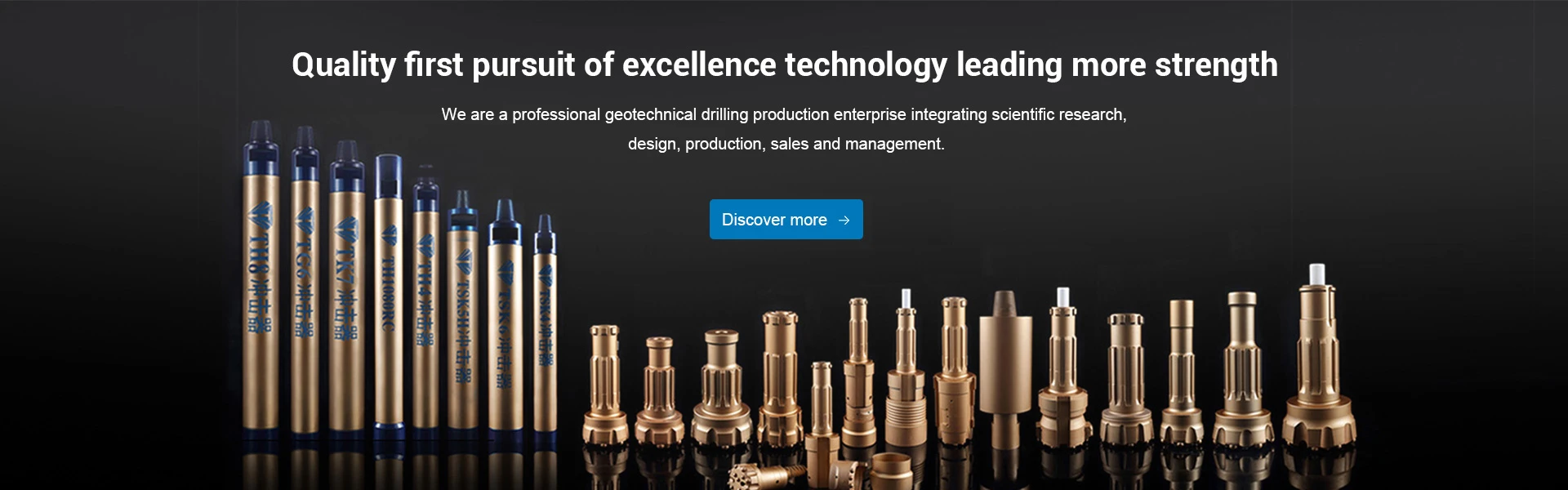

Exploring the Types of Rotary Hammer Drill Bits

When choosing the right drill bits for your rotary hammer, it's important to understand the different types available. One popular option is the SDS-Plus drill bits, designed for light to medium-duty applications. These bits feature a unique shank design that allows for efficient power transfer and reduced wear on the hammer drill. Another option is the SDS-Max drill bits, ideal for heavy-duty drilling tasks. These larger bits can withstand higher impact forces, making them perfect for tough materials like concrete and masonry. Lastly, spline shank drill bits offer excellent performance and durability for professional drilling applications.

1. SDS-Plus Drill Bits

SDS-Plus drill bits are known for their versatility and reliability in various drilling tasks. With their quick-change chuck system, these bits can be easily swapped out without additional tools, saving time and effort on the job site. The flute design of SDS-Plus drill bits helps to remove debris efficiently, reducing heat build-up and extending the lifespan of both the bit and the rotary hammer.

SDS-Plus drill bits are a professional favorite because they easily handle various drilling tasks. The quick-change chuck system allows for seamless bit swaps, eliminating the need for extra tools and streamlining the workflow on the job site. Additionally, the flute design efficiently removes debris and reduces heat build-up, ultimately extending the lifespan of both the bit and the rotary hammer. This makes SDS-Plus drill bits reliable and cost-effective for any drilling project.

2. SDS-Max Drill Bits

SDS-Max drill bits are a top choice for heavy-duty drilling jobs requiring extra power and durability. These robust bits feature a larger shank size and enhanced flute geometry to handle high-impact applications easily. With their advanced carbide tip design, SDS-Max drill bits deliver superior performance in challenging materials such as reinforced concrete and granite.

SDS-Max drill bits are designed for maximum power and durability, making them the go-to choice for heavy-duty drilling jobs. These robust bits' larger shank size and enhanced flute geometry allow them to handle high-impact applications, ensuring efficiency and precision effortlessly. With their advanced carbide tip design, SDS-Max drill bits offer superior performance in challenging materials such as reinforced concrete and granite, making them a reliable tool for professionals in construction and engineering.

3. Spline Shank Drill Bits

Spline shank drill bits are engineered to provide exceptional strength and stability during demanding drilling operations. Their solid connection with rotary hammers ensures maximum power transmission without slippage or wobbling, resulting in precise and efficient drilling performance. Spline shank drill bits are an excellent choice for professionals requiring consistent accuracy and reliability.

Factors to Consider When Selecting Drill Bits

When selecting rotary hammer drill bits, it's crucial to consider the material composition. Different materials, such as carbide, high-speed steel, or diamond, offer varying levels of durability and performance. Carbide-tipped drill bits are ideal for drilling into hard materials like concrete and masonry, while high-speed steel bits are better suited for wood and metal.

1. Material Composition

Choosing the right material composition for your rotary hammer drill bits is essential for achieving optimal drilling results. Carbide-tipped drill bits are known for their exceptional hardness and resistance to wear, making them suitable for heavy-duty applications in construction and geotechnical drilling. On the other hand, high-speed steel bits are more versatile and can easily handle a wide range of materials.

Due to their exceptional hardness and wear resistance, carbide-tipped drill bits are ideal for drilling through tough materials such as concrete, masonry, and stone. Their ability to maintain sharpness even under heavy loads makes them a reliable choice for heavy-duty construction and geotechnical drilling applications. On the other hand, high-speed steel bits offer versatility. They can easily handle a wide range of materials, making them suitable for general-purpose drilling tasks in various industries.

2. Bit Size and Length

The size and length of your rotary hammer drill bits play a significant role in determining their effectiveness. Larger bit sizes are better suited for drilling larger holes, while smaller sizes offer precision when working on intricate projects. Additionally, longer drill bits provide deeper penetration into materials, making them suitable for tasks that require extended reach.

In addition to size and length, it's important to consider the compatibility of your rotary hammer drill bits with your specific hammer drill. Some bits are designed specifically for use with certain hammer drills, so it's essential to ensure that your drill bits are compatible with your equipment. Using incompatible bits can result in poor performance and potential damage to both the drill and the bit. Always check the manufacturer's recommendations for compatible drill bits to ensure optimal results and equipment longevity.

3. Compatibility with Hammer Drills

Ensuring compatibility between your drill bits and hammer drills is crucial for seamless operation. Different rotary hammers may require specific shank designs or chuck systems to accommodate different drill bit types. It's important to verify that your chosen drill bits are compatible with your hammer drill to avoid operational issues during drilling tasks.

Now that we've covered the essential factors to consider when selecting rotary hammer drill bits, you'll be well-equipped to make informed decisions based on your specific drilling needs. Remember to prioritize material composition, bit size and length, and compatibility with your hammer drills to ensure efficient and effective drilling operations.

Tips for Maintaining and Preserving Drill Bits

1. Proper Cleaning and Storage

Cleaning after each use is crucial to ensure the longevity of your rotary hammer drill bits. Use a wire brush to remove debris and wipe them down with a cloth. Store them in a dry, cool place to prevent rust and corrosion.

After cleaning your rotary hammer drill bits, it's important to inspect them regularly for signs of wear and tear. Look for any chipping or dullness on the cutting edges, as this can affect the performance of the bits. If you notice any damage, replacing the bits is best to ensure smooth and efficient drilling.

2. Regular Inspection for Wear and Tear

Regularly inspect your hammer drill bits for signs of wear and tear, such as dullness or chipping. Replace any damaged or worn-out bits immediately to prevent compromising the quality of your drilling work.

After inspecting your hammer drill bits for wear and tear, you may find that some bits are simply dull and in need of sharpening rather than replacement. In such cases, it's important to use proper sharpening techniques to restore the cutting edges of the bits. This can be done using a bench grinder or a specialized bit sharpener, ensuring that the bits are honed to their original sharpness for optimal drilling performance.

3. Sharpening and Reconditioning Techniques

When your rotary hammer drill bits start to lose their sharpness, it's time to sharpen or recondition them. Invest in a quality bit sharpener or seek professional reconditioning services to restore the cutting edges for optimal performance.

As your rotary hammer drill bits start to lose their sharpness, investing in a quality bit sharpener or seeking professional reconditioning services to maintain their optimal performance is essential. A dull bit can decrease drilling efficiency and damage the material you're working with. By regularly sharpening or reconditioning your drill bits, you can ensure that they continue to deliver precise and clean cuts, saving you time and effort on the job.

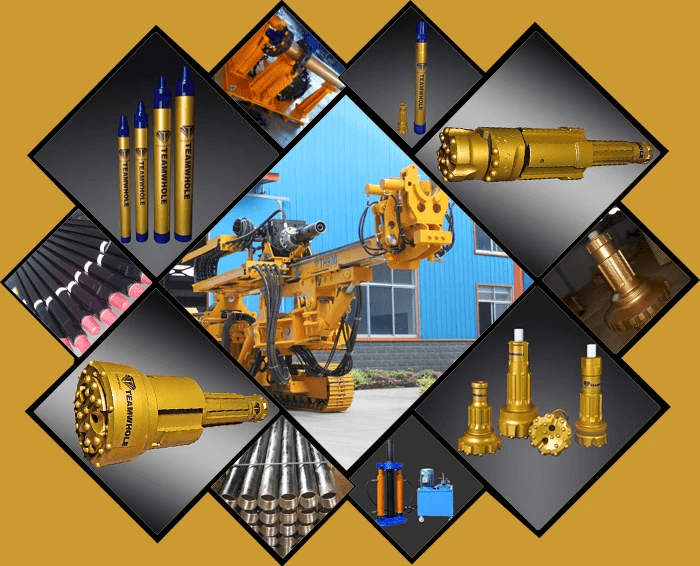

Tianhe: Leading Innovations in Rotary Hammer Drill Bits

Cutting-Edge Technologies

Tianhe is at the forefront of innovation in rotary hammer drill bits, constantly incorporating cutting-edge technologies to improve drilling efficiency and precision. Their use of advanced materials and engineering techniques ensures that their drill bits can easily handle the toughest drilling tasks.

Superior Durability and Performance

Tianhe's rotary hammer drill bits are renowned for their exceptional durability and performance, making them a top choice for geotechnical drilling professionals. Their superior strength allows for extended use without compromising on precision, providing a reliable solution for demanding drilling applications.

Customer Satisfaction and Testimonials

With a strong focus on customer satisfaction, Tianhe has garnered numerous positive testimonials from satisfied users of their rotary hammer drill bits. Customers consistently praise Tianhe's products' exceptional quality and performance, solidifying their reputation as a trusted provider of high-quality drill bits.

Furthermore, Tianhe's commitment to customer satisfaction extends beyond the quality of their products. Their responsive customer service team is always ready to address any concerns or inquiries, ensuring every customer has a positive experience with their purchase. This dedication to providing exceptional service further reinforces the trust and loyalty that customers have in Tianhe as a reliable provider of rotary hammer drill bits.

Invest in Quality Drill Bits

Investing in quality drill bits is crucial for enhancing your drilling efficiency. With the right rotary hammer drill bits, you can achieve precise and efficient drilling results, saving time and effort on your projects. Tianhe is your trusted partner in geotechnical drilling, offering cutting-edge technologies and superior durability to meet all your drilling needs.

Enhancing Your Drilling Efficiency

Choosing the right rotary hammer drill bits can significantly enhance your drilling efficiency. High-quality drill bits for hammer drills ensure smooth and accurate drilling, allowing you to complete your projects with precision and ease. With Tianhe's innovative technologies, you can experience unmatched performance and reliability in every drilling task. Investing in quality drill bits can save you time and money in the long run. Using durable and long-lasting drill bits can avoid frequent replacements and costly downtime, ultimately improving your overall productivity.

Quality should always be a top priority when investing in drill bits for a hammer drill. Inferior drill bits can lead to inefficiency, increased wear on equipment, and compromised results. Investing in premium rotary drill bits from Tianhe ensures long-lasting performance and exceptional results for all your geotechnical drilling projects.

Tianhe: Your Trusted Partner in Geotechnical Drilling

Tianhe is committed to providing the highest-quality rotary hammer drill bits designed to meet the demands of geotechnical drilling. Our dedication to customer satisfaction is reflected in our testimonials from satisfied clients who have experienced the superior performance of our products firsthand.

Our rotary hammer drill bits are engineered with precision and durability in mind, ensuring that they can withstand the toughest drilling conditions. With a focus on innovation and continuous improvement, Tianhe is constantly developing new technologies to enhance the performance of our products, giving our clients a competitive edge in their geotechnical drilling projects. Our dedication to excellence means you can trust Tianhe to deliver reliable and high-performing drill bits for all your drilling needs.