Introduction

When it comes to drilling techniques, down the hole drilling has been gaining popularity for its efficiency and precision. This method involves using a hammer to drill through rock formations, offering a more effective alternative to traditional top hammer drilling. The advantages of down the hole drilling are numerous, making it a preferred choice for various industries.

Understanding Down the Hole Drilling Techniques

Down the hole drilling, also known as DTH drilling, involves using a pneumatic hammer to create boreholes in hard rock formations. This technique is widely used in mining, construction, and geothermal exploration due to its ability to penetrate challenging terrains with ease.

Down the hole drilling is preferred in many industries due to its efficiency and accuracy. The pneumatic hammer used in DTH drilling delivers high-impact blows to the drill bit, allowing for rapid and precise penetration into the rock. This results in clean and straight boreholes, minimizing the need for additional reaming or other corrective measures.

Exploring Down the Hole Drilling Methods

One of the key aspects of down the hole drilling is the use of DTH hammers, which provide efficient and precise drilling capabilities. Additionally, down the hole hammer piling is another application of this method, offering a reliable solution for driving piles into the ground with minimal effort.

Down the hole drilling methods offer several advantages over other drilling techniques. The use of DTH hammers allows for deeper and more accurate drilling, making it ideal for mining and construction projects that require precision. Furthermore, the ability to drive piles into the ground with minimal effort using down the hole hammer piling makes this method a cost-effective and efficient solution for various applications. These advantages make down the hole drilling a popular choice for industries that demand high-performance drilling capabilities.

The Advantages of Down the Hole Drilling

The advantages of down the hole drilling are evident in its ability to achieve high penetration rates and accurate borehole placement. When compared to top hammer drilling, DTH offers superior performance in complex rock formations and provides better control over drilling operations.

In addition, down the hole drilling is known for its versatility in reaching greater depths and achieving more consistent results, making it an ideal choice for large-scale mining and construction projects. The ability to efficiently drill deeper into the earth's surface allows for increased access to valuable resources and the potential for larger-scale operations. Furthermore, DTH drilling equipment is designed to withstand the rigors of demanding drilling conditions, ensuring reliable performance even in challenging environments.

Down the Hole Drilling

When it comes to efficient down the hole drilling, Teamwhole’s DTH hammers are top-notch. These hammers are designed to deliver high performance and reliability in various drilling applications. With innovative features and advanced technology, Teamwhole’s DTH hammers ensure optimal productivity and cost-effectiveness for any drilling project.

Teamwhole’s Efficient DTH Hammers

Teamwhole’s DTH hammers are engineered to provide maximum energy transfer, resulting in faster drilling rates and reduced fuel consumption. Their durable construction and precision engineering make them ideal for challenging rock formations, ensuring consistent performance and longevity. Whether it's surface drilling or underground mining, Teamwhole’s DTH hammers deliver exceptional results, making them a preferred choice for professionals in the industry.

Top Hammer Drilling vs. Down the Hole Drilling

While top hammer drilling is suitable for smaller hole sizes and softer rock formations, down the hole (DTH) drilling is more effective for larger hole sizes and harder rock formations. With its ability to produce straighter holes with less deviation, DTH drilling offers greater precision and efficiency compared to top hammer drilling. This makes it a preferred choice for projects that require high accuracy and productivity.

While top hammer drilling may be more cost-effective and easier to operate, down the hole (DTH) drilling offers greater versatility and adaptability to various rock formations. Its ability to handle larger hole sizes and harder rock formations makes it a valuable choice for projects in challenging geological conditions. Additionally, DTH drilling allows for deeper hole depths, making it suitable for applications such as mining and quarrying where reaching significant depths is essential for extracting resources efficiently.

Down the Hole Hammer Piling

Down the hole hammer piling is a method commonly used in construction projects to drive piles into the ground with precision and power. The DTH hammer delivers powerful blows directly to the pile head, allowing for efficient driving into various soil conditions without causing damage to surrounding structures or the environment. This method is highly effective in creating stable foundations for buildings, bridges, and other structures.

Furthermore, down the hole hammer piling is a cost-effective method that can save time and labor on construction projects. With the ability to drive piles into the ground quickly and efficiently, this technique can help expedite the overall construction process, allowing for faster project completion and reduced labor costs. The precision and power of DTH hammers also contribute to minimizing the need for rework or adjustments, further streamlining the construction timeline.

Remember that using quality equipment like Teamwhole’s DTH hammers can significantly impact your project's success by ensuring high penetration rates and minimal downtime due to maintenance or repairs.

DTH Drilling Machine

When exploring DTH drilling machines, it's important to consider their efficiency and precision in down the hole drilling operations. These machines are designed to handle various rock formations and deliver consistent results, making them a popular choice for mining and construction projects. With advanced technology and durable components, DTH drilling machines offer reliability and high performance in challenging environments.

Exploring DTH Drilling Machines

DTH drilling machines are specifically designed for down the hole drilling, utilizing powerful hammers to break through hard rock formations with ease. These machines are equipped with efficient air compressors and sturdy drill rods, ensuring smooth operation and minimal downtime during drilling activities. With their versatility and adaptability, DTH drilling machines are essential for achieving productive results in demanding geological conditions.

DTH drilling machines offer a distinct advantage over rotary drilling in their ability to penetrate hard rock formations more efficiently. The powerful hammers used in DTH drilling deliver a stronger impact, allowing for quicker and more effective rock breaking. Additionally, the use of efficient air compressors ensures that the drilling process is not only powerful but also consistent, resulting in minimal downtime and increased productivity.

Difference between DTH and Rotary Drilling

One key difference between DTH and rotary drilling lies in the method of energy transfer to the drill bit. While rotary drilling relies on rotation to create boreholes, DTH drilling uses impact force from a hammer to penetrate rock formations effectively. This distinction makes DTH drilling more suitable for hard rock applications where top hammer or rotary methods may not deliver the same level of performance.

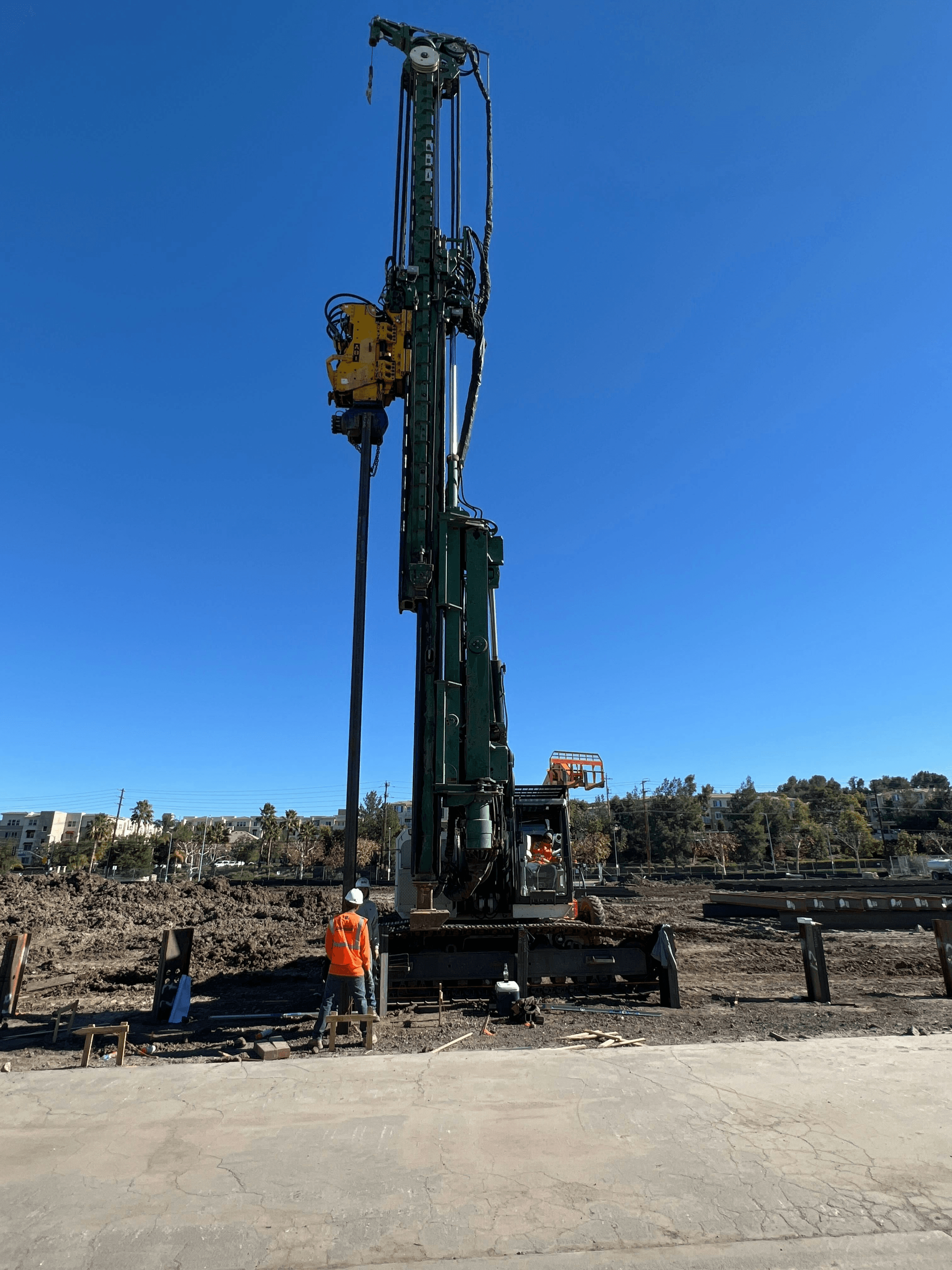

DTH Drilling Machine in Action

In action, a DTH drilling machine showcases its precision and power as it efficiently creates boreholes in challenging terrains. The down the hole hammer piling technique ensures that each impact from the hammer delivers maximum force to break through tough rock formations, resulting in smooth and consistent drilling operations. With its ability to achieve high penetration rates, the DTH drilling machine proves its effectiveness in various mining and construction projects.

The DTH drilling machine's versatility is evident in its ability to adapt to various ground conditions, including hard rock, gravel, and sand. Its precision and power allow for smooth and consistent drilling operations even in the most challenging terrains, making it an ideal choice for mining and construction projects. With its capability to achieve high penetration rates, the DTH drilling machine proves to be a reliable and efficient tool for creating boreholes with minimal downtime.

Down the Hole Drilling Method

When it comes to down the hole drilling method, it's important to understand the various techniques and equipment involved. From DTH hammers to drilling machines, each component plays a crucial role in achieving successful results. By mastering the ultimate guide to DTH drilling method, you can ensure that your drilling operations are efficient and effective.

The Ultimate Guide to DTH Drilling Method

Mastering the ultimate guide to DTH drilling method involves understanding the step-by-step process of how down the hole drilling works. From selecting the right equipment to optimizing drilling parameters, every detail matters in ensuring a smooth and productive operation. With proper training and expertise, you can maximize the potential of DTH drilling for various applications.

After mastering the step-by-step process of DTH drilling, it's essential to understand the challenges of drilling in complex rock formations. These formations can vary greatly in hardness, density, and composition, requiring careful consideration when selecting the right equipment and optimizing drilling parameters. With the expertise to navigate these challenges, DTH drilling can be effectively utilized in a wide range of geological conditions, from soft sedimentary rock to hard igneous formations.

DTH Drilling in Complex Rock Formations

One of the key advantages of down the hole drilling is its ability to tackle complex rock formations with ease. Unlike top hammer drilling, which may struggle with challenging geologies, DTH drilling excels in providing consistent performance even in difficult conditions. This makes it a preferred choice for projects that involve varying rock formations and densities.

Furthermore, DTH drilling is known for its high penetration rates, allowing for efficient and rapid progress in drilling through tough rock formations. This means that projects can be completed in a shorter timeframe, saving both time and money for the operators. The ability to achieve high penetration rates also contributes to minimizing wear and tear on equipment, reducing maintenance costs and downtime.

Achieving High Penetration Rates with DTH Drilling

The high penetration rates achieved with down the hole drilling are a result of its efficient energy transfer and impact force delivery. This allows for faster and more productive drilling compared to other methods such as rotary drilling. With its ability to rapidly advance through hard rock, DTH drilling proves to be a valuable asset in meeting tight project deadlines.

Furthermore, DTH drilling offers better accuracy and precision compared to rotary drilling, making it a preferred choice for projects that require specific hole sizes and depths. The impact force delivery of DTH drilling also results in minimal deviation, ensuring that the drilled holes are straight and true. This level of precision is crucial in industries such as mining and construction where exact measurements are essential for the success of the project.

Conclusion

When it comes to drilling techniques, down the hole drilling offers numerous advantages over other methods. With its ability to achieve high penetration rates and work efficiently in complex rock formations, it's clear that DTH drilling is a top choice for many industries. Choosing the right DTH drilling equipment is crucial to harnessing the full power of this technology.

Advantages of Down the Hole Drilling Techniques

One of the key advantages of down the hole drilling is its ability to achieve high penetration rates, making it a highly efficient method for various industries. Unlike top hammer drilling, DTH drilling allows for deeper and larger diameter holes, making it ideal for projects that require precision and power. Additionally, DTH hammer piling offers a cost-effective and reliable solution for foundation construction and mining operations.

In addition to its high penetration rates and ability to drill deeper and larger diameter holes, down the hole drilling techniques also offer greater accuracy and control. This precision is essential for projects that require specific hole sizes and angles, such as in the construction of oil and gas wells or geothermal drilling. The ability to achieve precise drilling also reduces the risk of errors or rework, ultimately saving time and costs for businesses in various industries.

Choosing the Right DTH Drilling Equipment

Selecting the right DTH drilling equipment is essential for maximizing productivity and achieving optimal results. With Teamwhole’s efficient DTH hammers and advanced drilling machines, companies can ensure smooth operations and superior performance in various geological conditions. Understanding the difference between DTH and rotary drilling is crucial in choosing the most suitable equipment for specific project requirements.

Harnessing the Power of DTH Drilling Technology

Harnessing the power of down the hole drilling technology involves utilizing cutting-edge equipment and following best practices in DTH drilling method. By exploring DTH drilling machines in action and understanding their capabilities, companies can leverage this technology to overcome challenges in complex rock formations and achieve remarkable results in their projects.