Introduction

Are you familiar with RC drilling, also known as reverse circulation drilling? This innovative method has revolutionized the geotechnical drilling industry, offering numerous benefits and precise sampling techniques. When it comes to RC Drilling, Tianhe is a leader in the field, providing top-quality equipment and expertise for all your drilling needs.

Understanding RC Drilling

RC drilling, or reverse circulation drilling, is a method used to collect rock samples quickly and efficiently. This technique involves using a dual-wall drill pipe system to retrieve rock cuttings up to the surface for analysis. With its ability to reach greater depths than traditional methods, RC drilling has become a popular choice for geotechnical projects.

RC drilling is also known for its ability to provide accurate and reliable samples, making it a preferred method for mining and exploration companies. The dual-wall drill pipe system ensures minimal sample contamination, resulting in high-quality data for analysis. This level of precision is crucial for making informed decisions about the viability of a potential mining site or the composition of rock formations.

Benefits of RC Drilling

Reverse Circulation (RC) drilling is a popular method used in the mining and exploration industry, primarily for mineral exploration. This technique offers several benefits over traditional drilling methods, such as diamond drilling or rotary air blast (RAB) drilling, making it a preferred choice for many projects. Here are some of the key benefits of RC drilling:

- Sample Quality: RC drilling provides high-quality, uncontaminated samples. The drilling mechanism ensures that the sample is not contaminated by fluids or materials from different depths. This is because the cuttings are returned to the surface inside the rods, minimizing the risk of contamination and providing a more accurate representation of the subsurface material.

- Speed: Compared to diamond drilling, RC drilling is faster. This increased drilling speed means that projects can be completed more quickly, reducing the time and cost associated with the exploration phase. The rapid penetration rates make it an efficient option for both shallow and deep drilling.

- Cost-Effectiveness: Although RC drilling might have higher upfront costs than some other methods (like RAB drilling), its speed and efficiency can make it more cost-effective in the long run, especially for deep drilling projects. It reduces the overall project cost by completing the drilling phase faster.

- Depth Capability: RC drilling can reach considerable depths, often several hundred meters, while still providing good sample quality. This makes it suitable for deep exploration projects where understanding the geology at depth is crucial.

- Versatility: RC drilling is versatile and can be used in a variety of geological settings, from hard rock to softer sedimentary environments. It's effective in a range of conditions and can be adapted to meet the specific needs of a project.

- Environmental Impact: The method has a relatively low environmental impact compared to some other drilling techniques. The process generates less waste and disturbance to the site, as the cuttings are collected at the surface for disposal or analysis, reducing the footprint of the drilling operation.

- Safety: RC drilling is considered safer than some other methods. The risk of accidents is reduced due to the method's inherent design and operation, which limits the exposure of workers to the drill hole and machinery.

- Water Use: Unlike diamond drilling, which requires large amounts of water, RC drilling can be more efficient in terms of water usage. This is particularly beneficial in arid regions where water resources are scarce.

The benefits of RC drilling include high-quality samples, speed, cost-effectiveness, depth capability, versatility, reduced environmental impact, safety, and efficient water use. These advantages make it a preferred method for many mineral exploration and mining projects.

Tianhe: A Leader in Geotechnical Drilling

When it comes to choosing the right equipment for your geotechnical drilling projects, Tianhe is your go-to partner. As a professional manufacturer specializing in research, design, production, sales, and management of geotechnical drilling rigs, Tianhe offers top-of-the-line solutions tailored to your specific needs. With a commitment to innovation and quality, Tianhe's rigs are designed to maximize efficiency and productivity on the job site. Whether you're working on soil investigation, foundation engineering, or mineral exploration, Tianhe has the expertise and equipment to ensure successful project outcomes.

The Basics of RC Drilling

RC drilling, also known as reverse circulation drilling, is a method used to collect rock samples quickly and efficiently. It involves using a dual wall drill pipe that allows the drill cuttings to be transported to the surface in a reverse circulation flow. This process ensures minimal contamination of the sample and provides accurate results for analysis.

RC drilling is a popular choice for mineral exploration and sample collection due to its speed and efficiency. The dual wall drill pipe used in RC drilling allows for continuous sample retrieval, eliminating the need for frequent stops to clear the holes of cuttings. This results in significant time savings compared to other drilling methods, making RC drilling an attractive option for projects with tight deadlines or budget constraints.

How RC Drilling Works

The RC drilling rig operates by using compressed air to drive a rotating hammer into the ground, which then breaks up the rock formation. The cuttings are forced up through the inner tube of the drill pipe and collected at the surface for further examination. This method is preferred for its ability to provide high-quality samples with minimal disturbance to the surrounding environment.

The equipment needed for RC drilling includes a drill rig, air compressor, and drill pipe. The drill rig is essential for supporting the drilling operation and providing stability. The air compressor is used to generate the compressed air needed to power the rotating hammer, while the drill pipe serves as a conduit for transporting the cuttings to the surface. Each of these components plays a crucial role in ensuring the efficiency and effectiveness of the RC drilling process.

Equipment Needed for RC Drilling

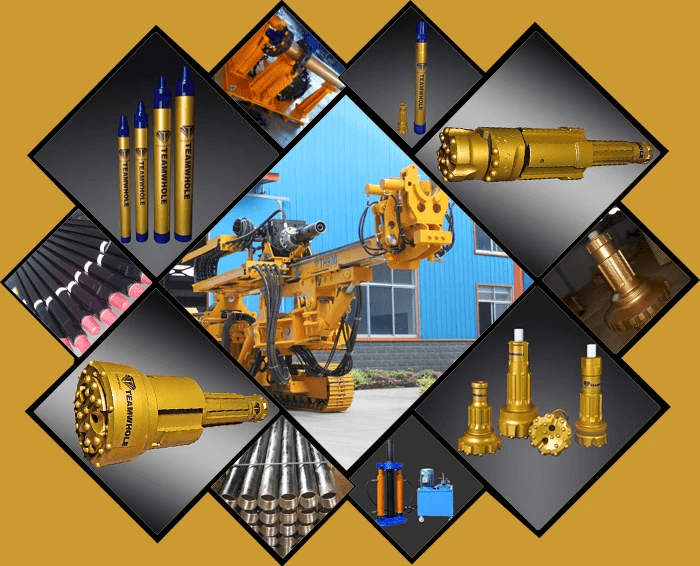

The key equipment needed for RC drilling includes an RC drill rig, reverse rotary drilling tools, compressors, and sampling systems. The RC drill rig is essential for its ability to operate and control the drilling process efficiently. At the same time, reverse rotary drilling tools are used to break up the rock formation effectively.

In addition to the RC drill rig and reverse rotary drilling tools, compressors are also a crucial piece of equipment for RC drilling. These compressors provide the necessary power to drive the drilling process and ensure efficient operation of the rig. Without the compressors, the drilling operation would not be able to function at its full capacity, making them an indispensable part of the equipment needed for RC drilling.

Applications of RC Drilling

RC drilling is commonly used in mineral exploration, geotechnical investigation, and environmental assessment projects. It is ideal for obtaining accurate samples in a variety of geological formations, including hard rock and unconsolidated materials such as sand and gravel.

RC drilling is also favored for its efficiency in reaching greater depths compared to other drilling methods, making it a valuable tool for exploration in remote or challenging terrains. Additionally, the minimal waste produced during RC drilling operations reduces environmental impact and allows for easier site remediation. This method's ability to provide continuous and reliable samples aids in the accurate assessment of mineral resources and environmental conditions, making it an indispensable technique in various industries.

Advantages of RC Drilling

1. Cost Efficiency of RC Drilling

One of the key advantages of RC drilling is its cost efficiency. The use of a reverse circulation drilling rig allows for faster and more efficient drilling, reducing overall project costs. With the ability to drill deeper and faster than traditional methods, RC drilling rigs save both time and money, making them an attractive option for geotechnical projects.

Additionally, RC drilling provides precise sampling, allowing for accurate analysis of soil and rock formations. This precision is crucial in geotechnical projects where the composition of the earth is a determining factor in project success. The ability to obtain high-quality samples efficiently reduces the need for re-drilling or additional testing, saving both time and resources. As a result, RC drilling offers a cost-effective solution for obtaining reliable data for geological and geotechnical studies.

2. Precise Sampling with RC Drilling

RC drilling provides precise sampling, allowing for accurate data collection in geotechnical projects. The use of an RC drill rig ensures that the samples collected are representative of the subsurface conditions, providing valuable information for engineering and construction purposes. This level of precision is crucial in ensuring the success and safety of any project.

RC drilling not only provides precise sampling for geotechnical projects but also offers environmental benefits. By accurately collecting data from the subsurface, RC drilling minimizes the need for additional exploration and reduces the environmental impact of construction projects. This method allows for targeted and efficient drilling, reducing the disturbance to surrounding ecosystems and minimizing waste generation. As a result, RC drilling is not only crucial for project success and safety but also contributes to sustainable and environmentally friendly practices in the construction industry.

3. Environmental Benefits of RC Drilling

In addition to its cost efficiency and precision, RC drilling also offers environmental benefits. The use of a reverse rotary drilling method minimizes waste and disturbance to the surrounding environment, making it a more sustainable option for geotechnical exploration and construction projects. This eco-friendly approach aligns with modern environmental standards and regulations.

Tianhe is at the forefront of developing innovative solutions for geotechnical drilling, including advanced RC drill rigs that offer unparalleled efficiency, precision, and environmental sustainability.

Investing in Tianhe's cutting-edge technology can provide significant advantages for your geotechnical projects while also contributing to a more sustainable future for the industry.

Key Considerations for RC Drilling

1. Site Preparation for RC Drilling

Before commencing any RC drilling project, it is crucial to prepare the site properly. This involves clearing the area of any obstacles that may obstruct the drilling rig and ensuring that the ground is stable and level to support the equipment. Additionally, it is essential to conduct a thorough survey of the site to identify any potential hazards or environmental concerns that may affect the drilling process.

After ensuring the site is clear and stable, it is important to establish clear safety measures for the RC drilling project. This includes providing adequate training for all personnel involved in the drilling process, as well as implementing strict protocols for handling equipment and materials. Additionally, it is crucial to have emergency response procedures in place in case of any accidents or unexpected events during the drilling operation.

2. Safety Measures for RC Drilling

Safety should always be a top priority when undertaking any drilling project.

- Implement strict safety protocols and provide comprehensive training for all personnel involved in the operation of the RC drilling rig. This includes wearing appropriate personal protective equipment, following safe operating procedures, and conducting regular maintenance checks on all equipment to ensure optimal performance and minimize the risk of accidents.

- Conduct regular safety audits and risk assessments to proactively identify and address potential hazards. This proactive approach can help prevent accidents and ensure the well-being of all personnel on-site. Additionally, providing ongoing safety training and promoting a culture of safety awareness among all team members can further enhance the overall safety measures for RC drilling operations.

Choosing the Right RC Drilling Contractor

Selecting a reputable and experienced RC drilling contractor is paramount to the success of your project. Look for a company with a proven track record in reverse circulation drilling, state-of-the-art RC drill rigs, and a team of skilled professionals who are knowledgeable about the latest industry standards and best practices. Tianhe, as a leader in geotechnical drilling, offers top-notch services and cutting-edge technology to meet your specific project requirements.

By paying close attention to these key considerations for RC drilling, you can ensure that your project runs smoothly and efficiently while minimizing risks and maximizing results.

Conclusion

RC drilling is revolutionizing the geotechnical drilling industry, and the future looks bright for this innovative technology. With continuous advancements in RC drill rigs and reverse rotary drilling techniques, we can expect even greater efficiency and accuracy in sampling for various projects.

With the increasing demand for more sustainable and environmentally friendly drilling methods, RC drilling is well-positioned to meet these needs. The use of water-based drilling fluids and minimal waste generation make RC drilling an attractive option for projects with strict environmental regulations. This eco-friendly approach not only benefits the environment but also enhances the overall reputation of the project and the companies involved.

Investing in RC drilling for your projects is a smart move, as it offers cost-effective solutions and precise sampling that can greatly benefit your overall project success. Whether it's for mining, construction, or environmental purposes, RC drilling is a reliable choice that delivers results. Additionally, with the advanced technology and equipment used in RC drilling, you can expect faster drilling times and increased productivity on your projects. This means you can save both time and money while still achieving high-quality results.

Tianhe has established itself as a trusted partner in geotechnical drilling, with a strong reputation for producing high-quality RC drill rigs and providing exceptional support to its clients. With Tianhe by your side, you can be confident in the success of your drilling projects.

Tianhe's commitment to innovation and continuous improvement ensures that its RC drill rigs are always at the forefront of technological advancements. This means that when you choose Tianhe, you are investing in cutting-edge equipment that will streamline your drilling operations and deliver superior results. By staying ahead of the curve, Tianhe demonstrates its dedication to meeting the evolving needs of the geotechnical drilling industry.