- …

- …

CASING DRILING SYSTEM

A casing drilling system is an innovative method in which the drilling casing itself also acts as the drill string during the drilling process. This integrated system involves drilling and simultaneously casing the borehole, providing stability to the wellbore and preventing collapses. Casing drilling systems streamline the drilling process, reduce environmental impact, and enhance overall efficiency in oil and gas exploration and well construction.

⬅ Go Back

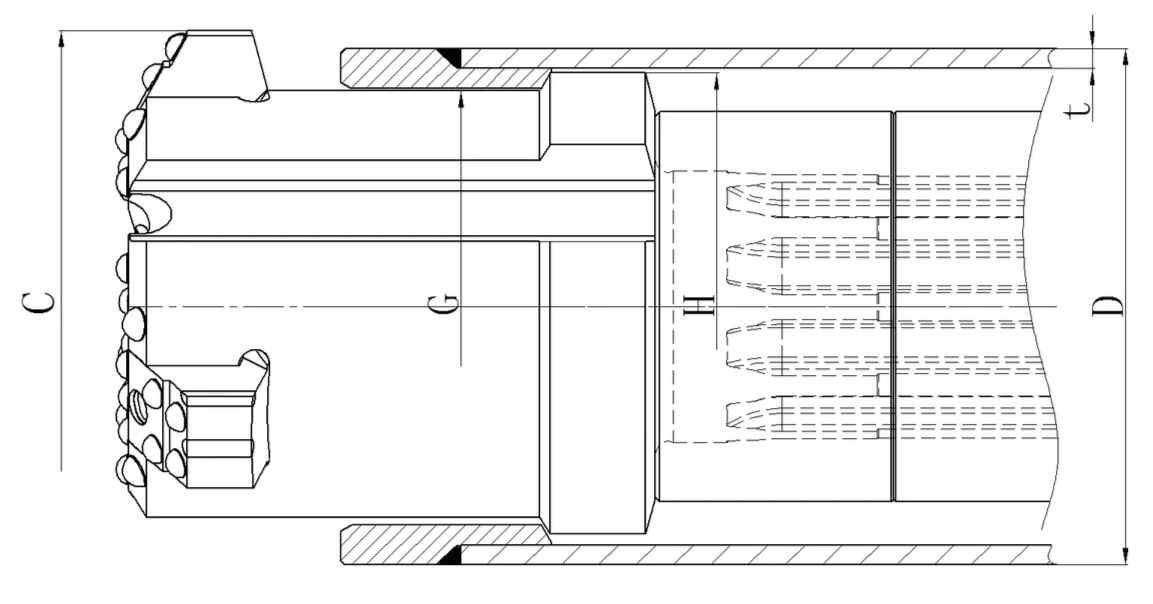

Concentric Casing System With Blocks

Applicables:

The surface of the stratum is mostly covered by loose material, sand and mud layers, backfill layers (without boulders), etc

Components:

1. When drilling starts,the pilot bit drives the casing shoe and casing tube down.

2. When reaching the bedrock, reverse rotation of the tool and pull the pilot bit out.

3. The casing tube can be left in the hole or grouting can be done while the tube is being pulled out.

4. Use normal bit to drill to the desired depth.

Features:

- The system is reinforced to be more wear-resistant;

- The structure has good concentricity, and the torque transmission is reasonable and smaller;

- The unique locking system structure is adopted to make the connection reliable (locking pin, steel ball);

- The straightness of the hole is high;

- The operation is simple and the cost is low compared to concentric drill bits;

- There is a phenomenon of drill jamming when encountering complex rock formations.

System composition:

Applications:

- Pile foundation (foundation of high-rise buildings, bridge piers. etc.);

- Water well wall protection.

Specifications:

GET A QUOTE NOW!