- …

- …

CASING DRILING SYSTEM

A casing drilling system is an innovative method in which the drilling casing itself also acts as the drill string during the drilling process. This integrated system involves drilling and simultaneously casing the borehole, providing stability to the wellbore and preventing collapses. Casing drilling systems streamline the drilling process, reduce environmental impact, and enhance overall efficiency in oil and gas exploration and well construction.

⬅ Go Back

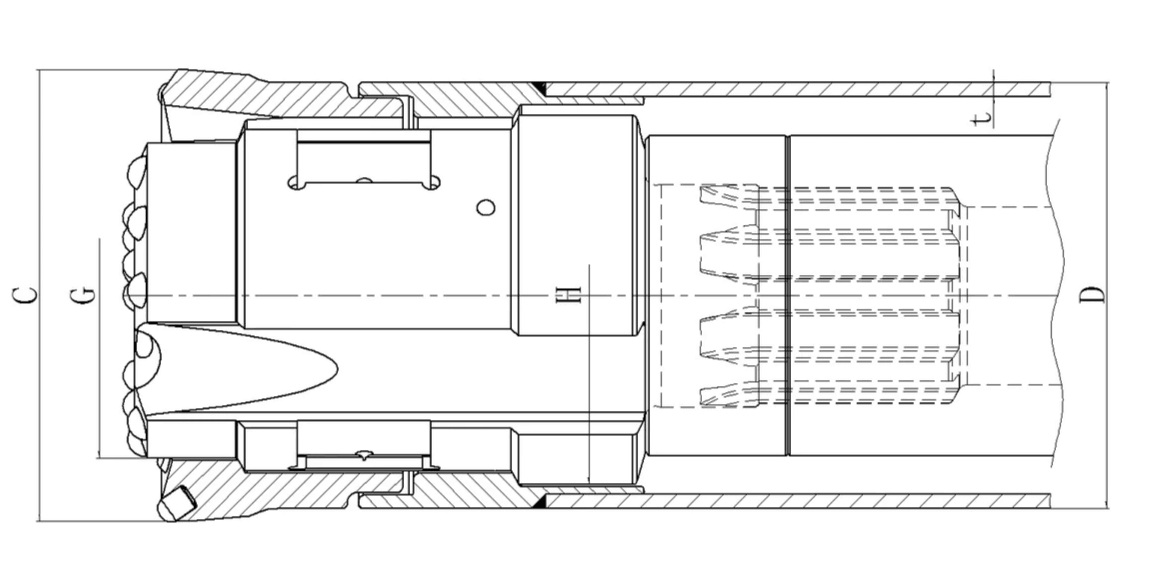

Concentric Casing System with Ring Bits

Applicables:

It is suitable for covering layers with more complex geological conditions, such as pebbles, cracks, dead stones, boulders, construction backfill waste, etc.

Components:

1. When the drilling starts, the pilot bit drive the ring bit down to the hole, followed the casing shoe and casing tube.

2. When drilling the bedrock, reserve rotation of the tools and pull the pilot bit out from the hole, leaving the ring bit in the hole.

3. Pour the concrete or do the next construction work.

4. Using normal bit to drill to the desried depth

Applications:

- Geological disaster prevention and control (anchor cables, anchoring, landslied prevention and control, high slope stabilization);

- Curtains and cofferdams (curtains and cofferdams of hydropower stations, reservoirs, etc.);

- Building foundation treatment (slope support treatment of high-rise buildings, bridge piers, deep foundation pits, etc.);

- Tunnel pipe shed support (support treatment of highwat and railway tunnels);

- Water well wall protection.

Specifications:

GET A QUOTE NOW!